Light-diffusing laminated film

A technology of light diffusing films and laminates, applied in optics, optical components, layered products, etc., can solve the problems of improving the brightness of components that are not mentioned, and achieve high brightness, improve the homogeneity of brightness, and improve brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0285] Hereinafter, examples are given to describe the present invention more specifically, but the present invention is not limited by the following examples, and can also be appropriately modified and implemented within the scope of the gist of the present invention, and these are included in the technical scope of the present invention. In addition, the measurement and evaluation methods used in the Examples are as follows. In addition, in the examples, "parts" means "parts by mass" unless otherwise stated, and "%" means "mass%" unless otherwise stated.

[0286] 1. Total light transmittance

[0287] A device with an integrating sphere (ISR-3100; manufactured by Shimadzu Corporation) was installed in a self-recording spectrophotometer (UV-3150; manufactured by Shimadzu Corporation), and a wavelength of 300 to 800 nm was scanned at high speed with a slit width of 12 nm. range, spectroscopic measurement is performed, expressed as the transmittance at 550nm.

[0288] In this ...

manufacture example 1

[0349] Using two melt extruders, 35 parts by mass of a cyclic polyolefin-based resin (TOPAS(TM) 6013S-04 manufactured by Topas Advanced Polymers, melt flow rate: 2.0 (230°C)) was mixed with the first extruder. A block copolymer resin formed of ethylene and octene (INFUSE(TM) D9817.15 manufactured by Dow Chemical Company, melt flow rate: 26 (230°C)) was used as a light diffusion layer in 65 parts by mass, and the second extrusion Machine, so that the polypropylene adhesive resin (Adomer(TM) SE800 manufactured by Mitsui Chemicals Co., Ltd., melt flow rate: 5.7 (190°C)) is used as the two surface layers, after melted and co-extruded with a T-die method , and cooled with a mirror-surface cooling roll to obtain an internal light-diffusing film having a total thickness of 400 μm and having heat-adhesive layers laminated on both surfaces. Adhesion between the film and the cooling roll during the above-mentioned cooling is performed using a vacuum chamber. The layer thickness composi...

manufacture example 2

[0352]Cyclic polyolefin-based resin (TOPAS (TM) 6015 manufactured by Topas Advanced Polymers, melt flow rate: 0.41 (230° C.)) 50 parts by mass and block copolymer resin composed of ethylene and octene (manufactured by Dow Chemical Co. Melt flow rate of INFUSE (TM) D9817.15: 26 (230°C)) 50 parts by mass, melt-mixed at a resin temperature of 250°C with an extruder PCM45 manufactured by Ikegai Iron Works Co., Ltd., and extruded with a T-die , cooled with a textured cooling roll (Ra=0.55) to obtain an internal light-diffusing film having a thickness of 400 μm. It should be noted that, as the surface opposite to the above-mentioned cooling roll, a squeeze roll whose surface was subjected to a release treatment (Ra=1.0) was used.

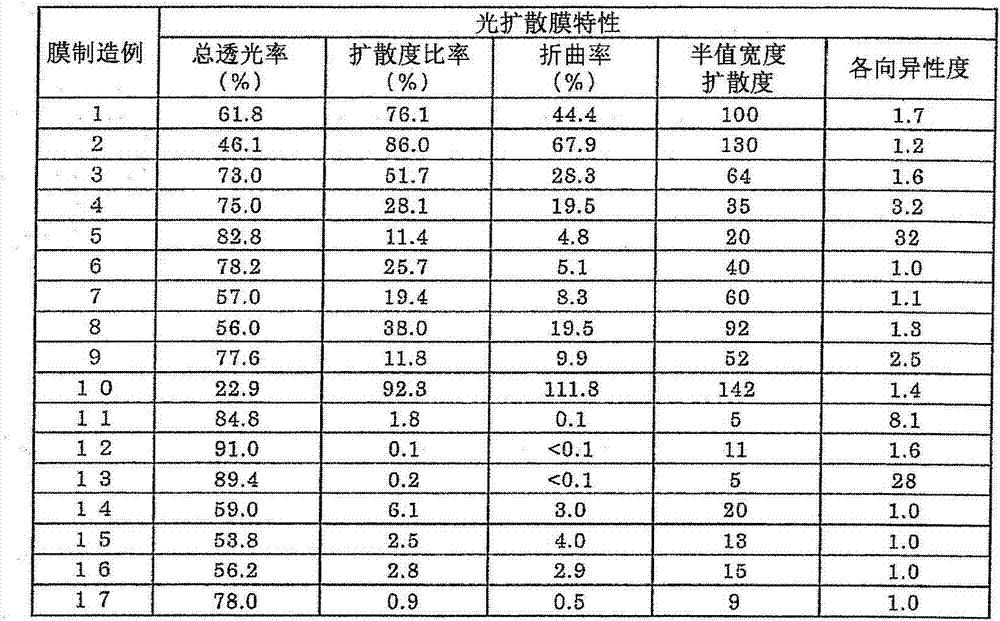

[0353] Table 1 shows the properties of the obtained inner light-diffusing film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com