Brightening film

A brightness-enhancing film and microstructure technology, applied in the direction of diffusion elements, prisms, etc., can solve the problems of difficult processing of structural wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

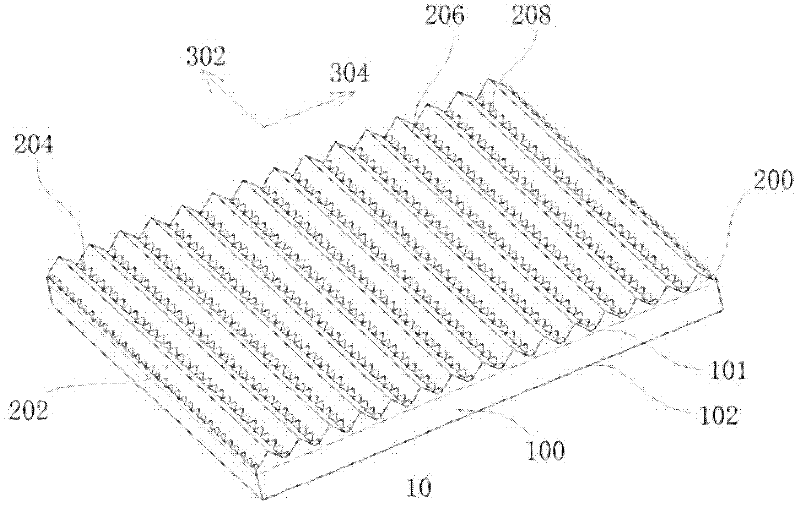

[0033] figure 1 It is the first embodiment of the present invention. Such as figure 1 As shown, polyethylene terephthalate is first selected as the substrate 100 . One surface of the substrate is the first optical surface 101 , and the opposite surface is the second optical surface 102 . On the first optical surface 101 of the substrate, a layer of polyethylene ultraviolet curable resin is coated, and the ultraviolet curable resin is pressed with a mold wheel, and irradiated with ultraviolet light to cure it, and the first optical surface arranged on the substrate 100 is obtained. The microstructure layer 200 on the surface 101.

[0034] The microstructure layer 200 produced by the above lamination includes primary microstructures 202 and secondary microstructures 204 .

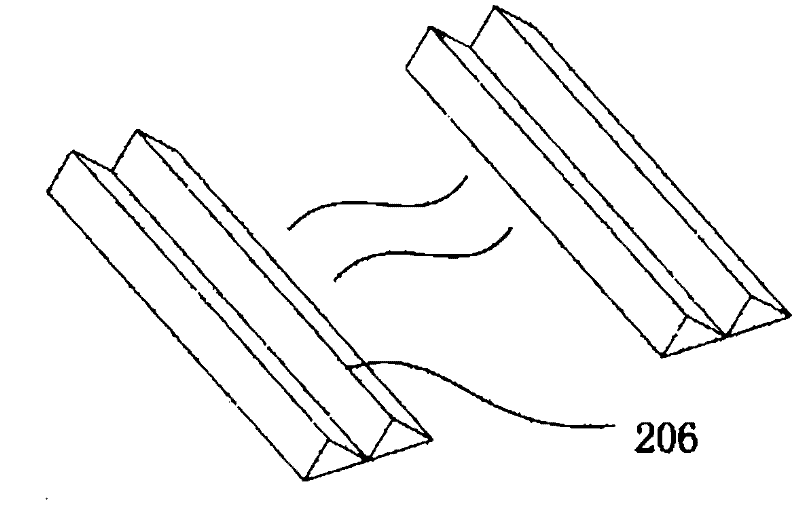

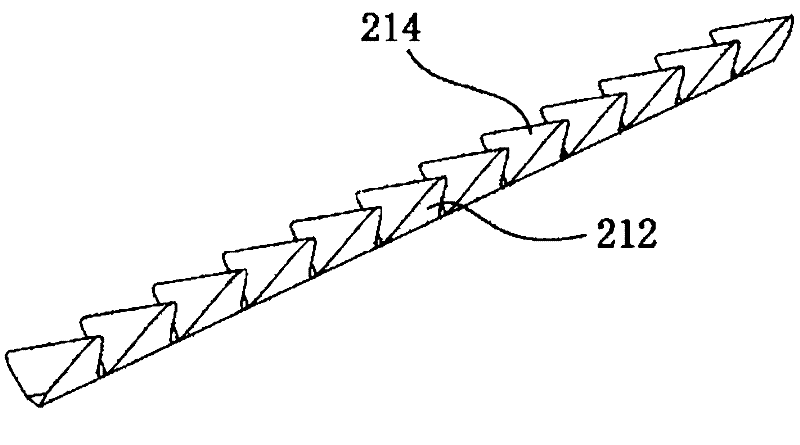

[0035] Such as figure 2 As shown in the schematic diagram of the main microstructure, the main microstructure 202 is composed of a plurality of main microstructure units 206 extending along the first di...

Embodiment 2

[0040] Figure 7A and Figure 7B It is a schematic diagram of the second embodiment of the present invention. Such as Figure 7A Brightness enhancing film 20 shown with figure 1 Brightness enhancing film 10 is shown similarly, additionally as Figure 7B As shown in the schematic cross-sectional view of the second embodiment of the brightness-enhancing film along the second direction, their difference is that the main microstructure is an isosceles triangle with a radius of 2um rounded corners on the cross-section perpendicular to the first direction. Due to the arc-shaped facets of the microstructure prism, it can play an anti-scratch role during the assembly of the brightness enhancement film, so as to improve the product assembly yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com