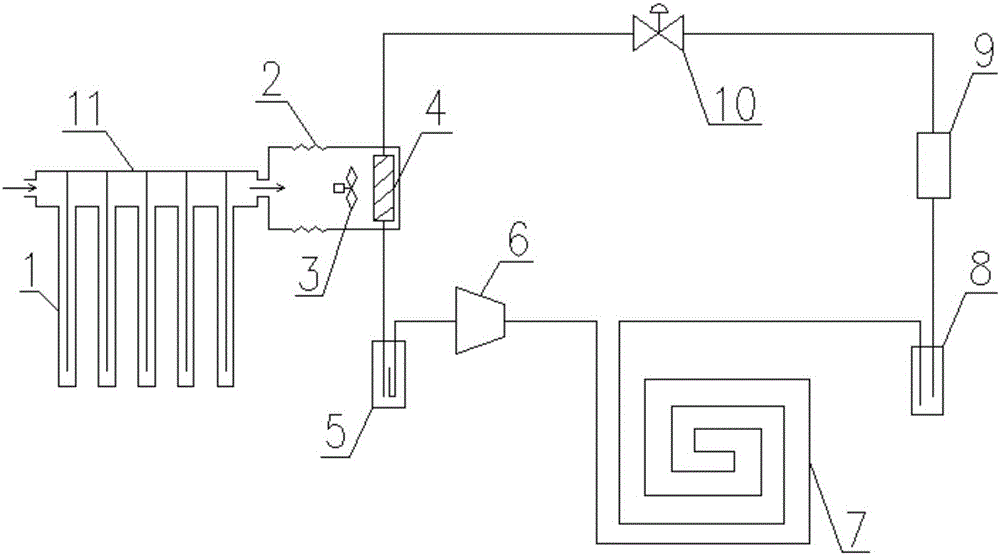

Solar-air source combined heat pump water-free heating system with heat storage function

A technology for heating systems and solar collectors, applied in the field of solar-air source composite heat pump heating systems, can solve problems such as the performance of the evaporator frosting system, reduce intermediate heat transfer processes, solve low system performance, and solve The effect of evaporator frosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

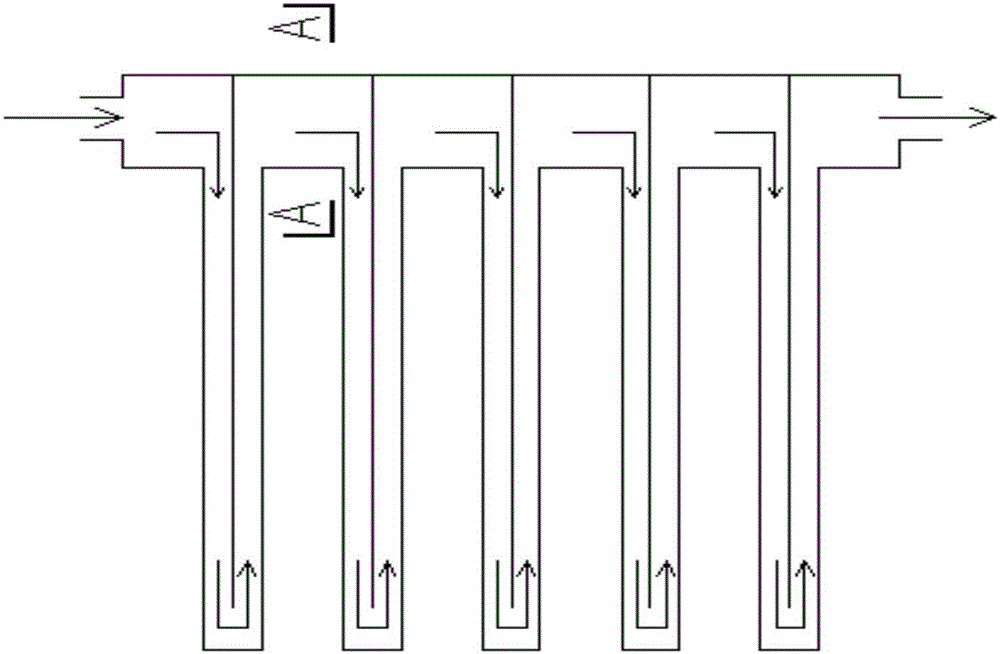

[0061] The solar heat collector 1 includes 5 vacuum heat collecting tubes, and the 5 vacuum heat collecting tubes are installed side by side on the heat collecting tube collector 11, and the two ends of the heat collecting tube collector 11 are respectively provided with an air inlet and an air outlet, and the heat collecting One end of the plate is fixed on the heat collecting tube collector 11, and the other end extends into the vacuum heat collecting tube, leaving a certain distance between the heat collecting plate entering the vacuum heat collecting tube and the bottom of the vacuum heat collecting tube. The heat collecting plate acts as a barrier to the circulation of air and introduces air into the vacuum heat collecting tube. Since the vacuum heat collecting tubes are installed side by side, the air flows through the five vacuum heat collecting tubes in sequence, and flows in an "S" shape in the solar heat collector 1 .

[0062] The outdoor temperature is -15°C, the fa...

Embodiment 2

[0068] The solar heat collector 1 includes 5 vacuum heat collecting tubes, and the 5 vacuum heat collecting tubes are installed side by side on the heat collecting tube collector 11, and the two ends of the heat collecting tube collector 11 are respectively provided with an air inlet and an air outlet, and the heat collecting One end of the plate is fixed on the heat collecting tube collector 11, and the other end extends into the vacuum heat collecting tube, leaving a certain distance between the heat collecting plate entering the vacuum heat collecting tube and the bottom of the vacuum heat collecting tube. The heat collecting plate acts as a barrier to the circulation of air and introduces air into the vacuum heat collecting tube. Since the vacuum heat collecting tubes are installed side by side, the air flows through the five vacuum heat collecting tubes in sequence, and flows in an "S" shape in the solar heat collector 1 .

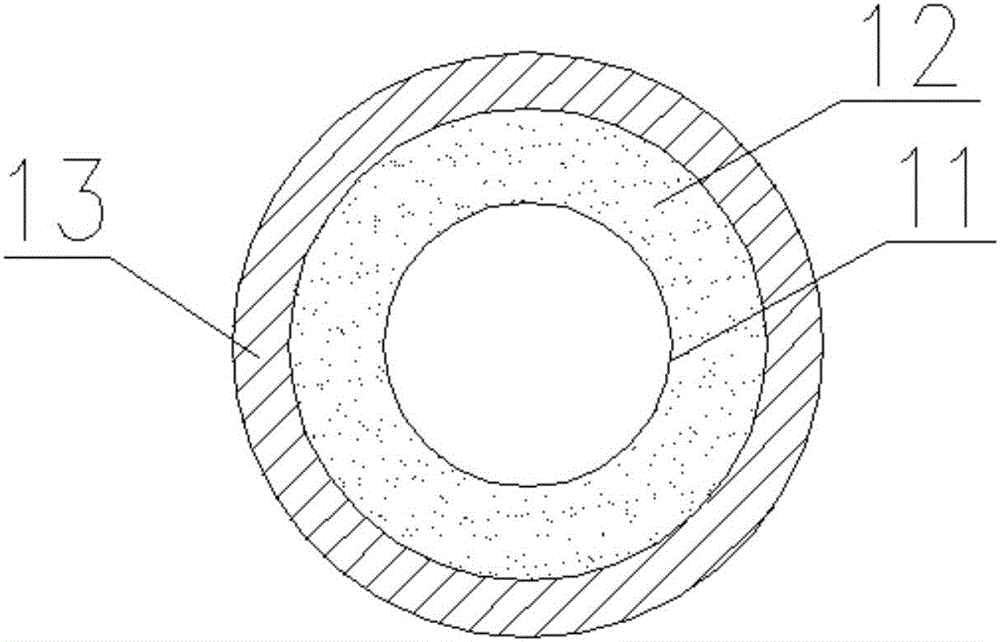

[0069] Such as image 3 As shown, the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com