Burners, burner arrays and combustion units with adjustable flow nozzles

A flow nozzle, adjustable technology, applied in the direction of burner, gas fuel burner, combustion type, etc., can solve the problems of easy oscillation, combustion instability, etc., to improve accuracy and speed, reduce dwell time, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to specific embodiments and drawings.

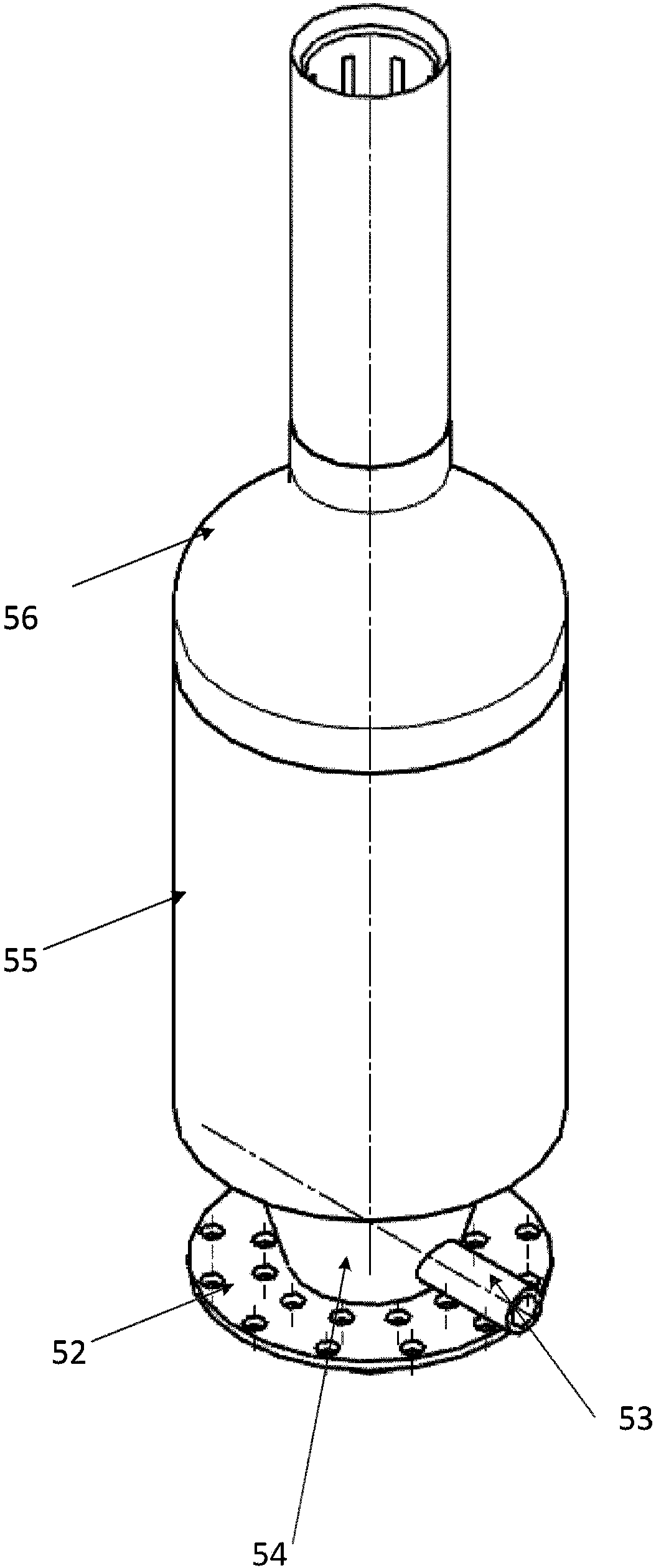

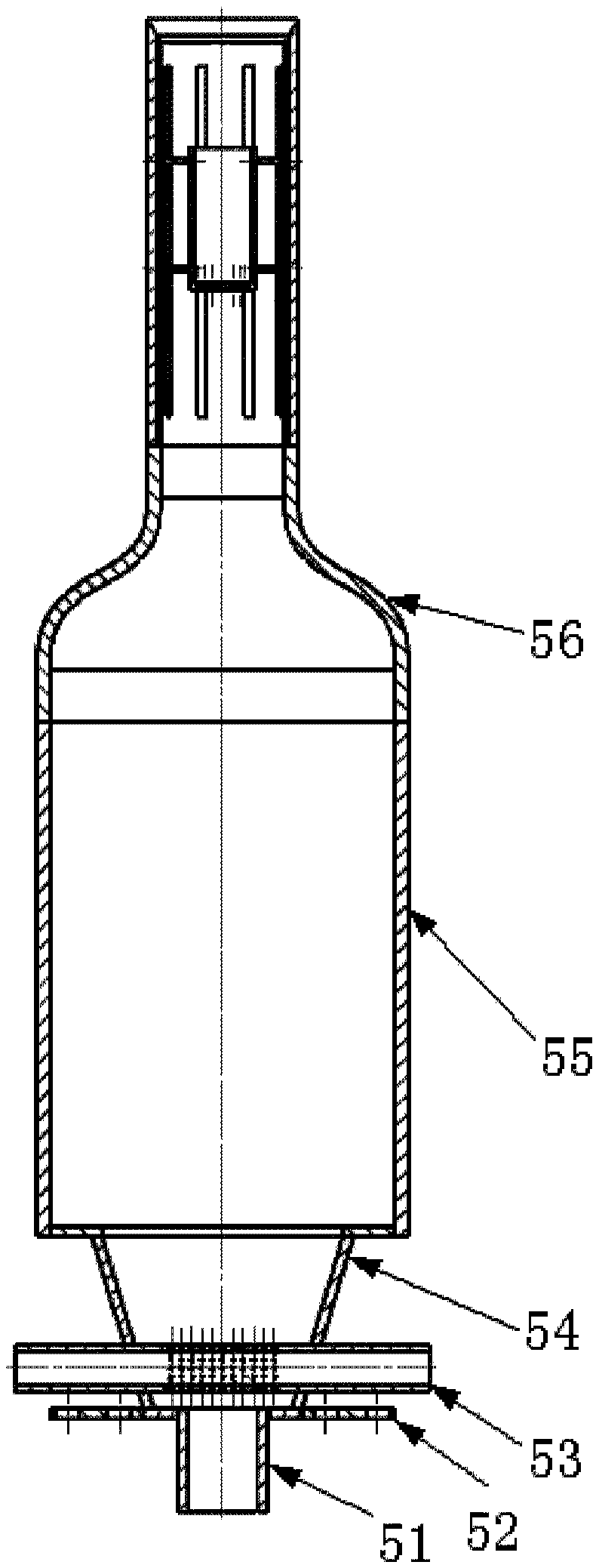

[0031] See figure 1 with image 3 , The burner with adjustable flow nozzle according to the first embodiment of the present invention includes: adjustable flow nozzle and blending rectifier. Along the upstream to downstream direction of the airflow, the blending rectifier includes air pipe 51, fixed The plate 52, the fuel pipe 53, the mixing section 54, the stabilizing section 55, and the shrinking section 56.

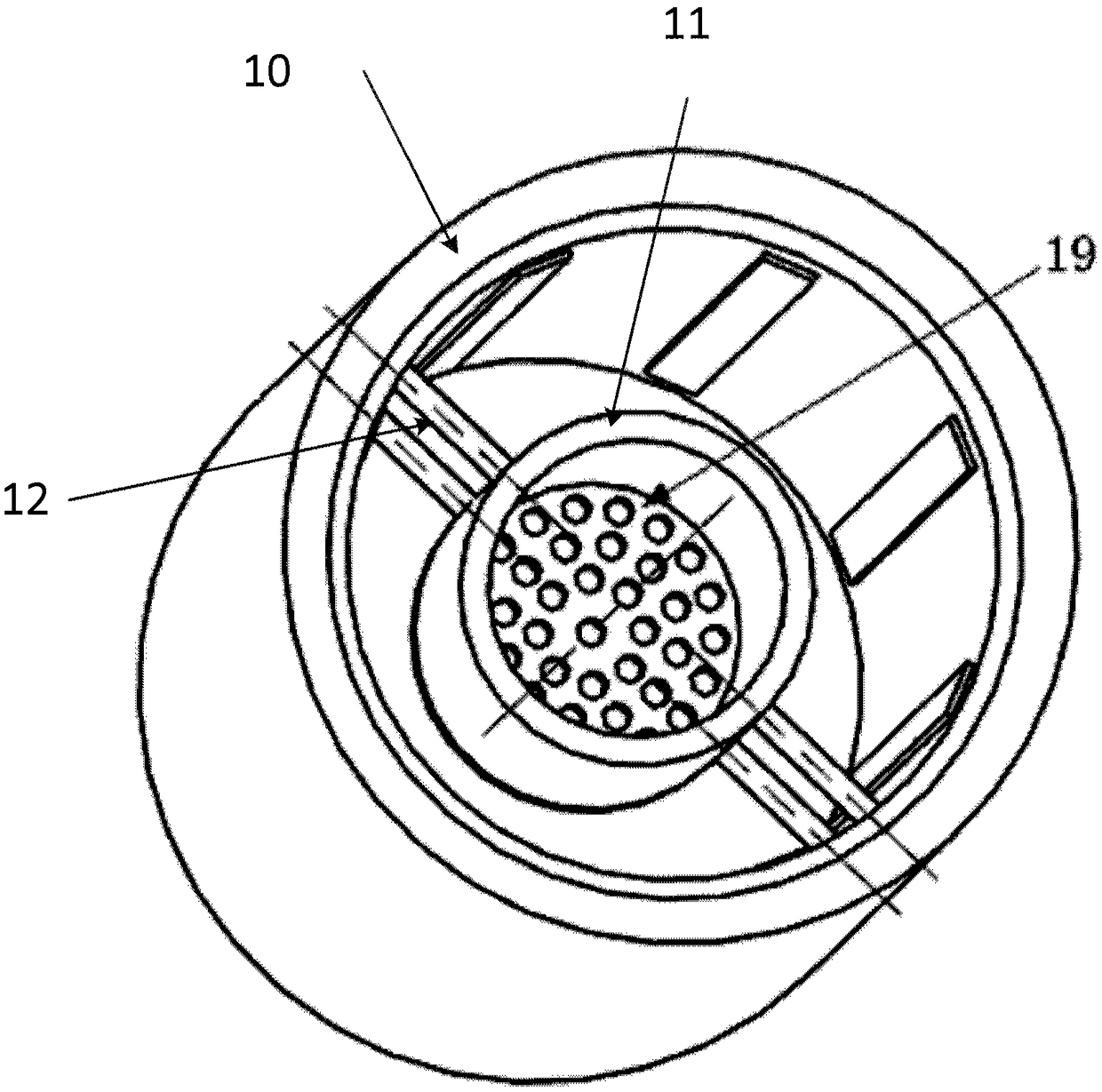

[0032] Among them, see figure 2 , The adjustable flow nozzle includes an outer cylinder 10 and an inner cylinder 11. An inner flow passage 18 is formed inside the inner cylinder, and an outer flow passage 17 is formed between the inner cylinder 11 and the outer cylinder 10. The airflow inlet of the inner cylinder 11 is equipped with a turbulent gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com