A kind of limestone powder preparation process

A technology of limestone powder and preparation process, applied in the field of limestone powder processing, can solve the problems that fine powder and coarse powder cannot be completely separated, unfavorable passage of fine powder, and smaller blade clearance, etc., and achieves ideal classification effect, improved classification effect and reduced reduction. Effect of Small Axial Velocities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

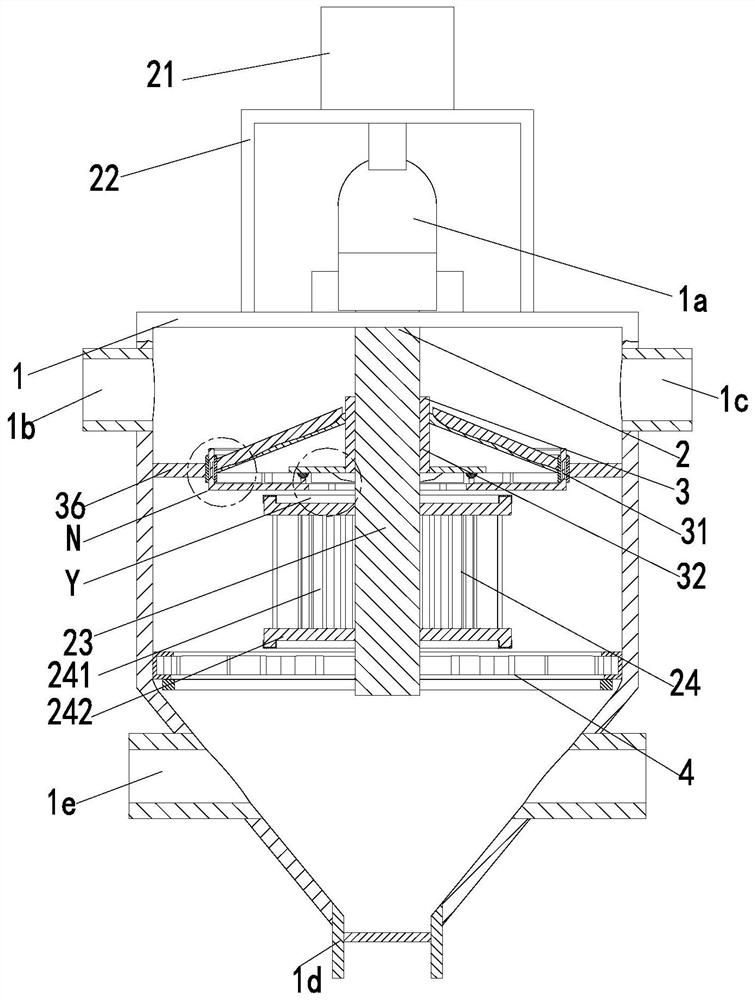

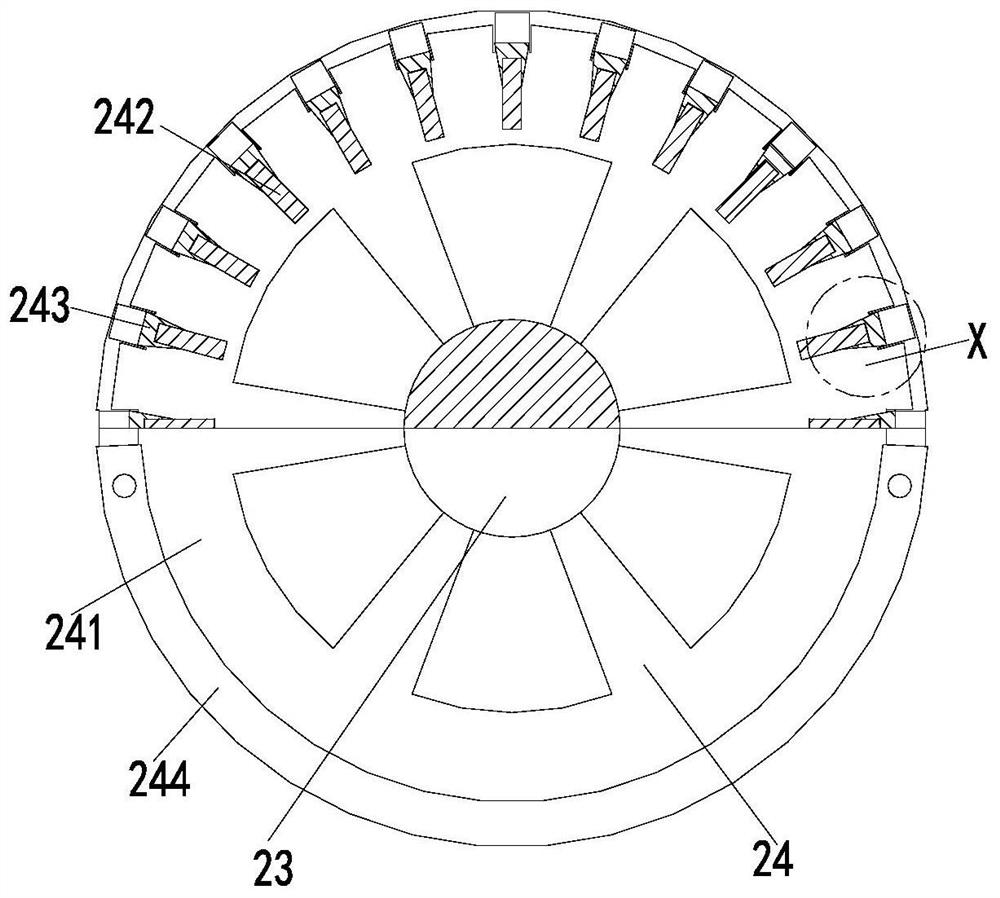

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

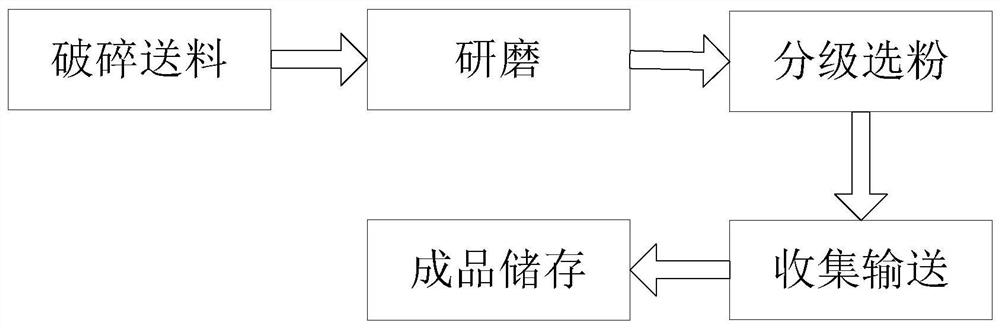

[0038] Such as Figure 1 to Figure 7 Shown, a kind of limestone powder preparation process mainly comprises following preparation steps:

[0039] S1 crushing and feeding, use the jaw crusher to crush the large limestone to obtain limestone fragments, and then transport the limestone fragments to the storage bin through the bucket elevator, the size of the limestone fragments is controlled at 30-40mm;

[0040] S2 Grinding, through the vibrating feeder, the limestone fragments are evenly sent to the European mill for grinding in batches to obtain limestone powder;

[0041]S3 graded powder selection, after the powder selection equipment is connected to the circulating fan, the limestone powder is sent to the powder selection equipment to separate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com