Jet pump with volute type flume

A water diversion chamber and volute type technology, applied in the field of jet pumps, can solve problems such as internal flow field deflection, operating condition deviation, loss, etc., and achieve the effects of reducing hydraulic loss along the process, uniform flow velocity distribution, and improved hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

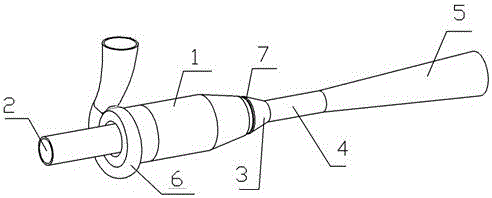

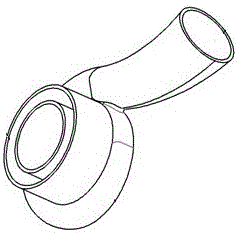

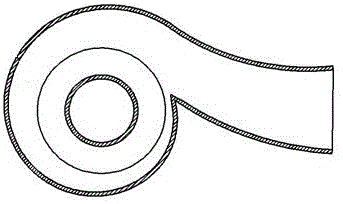

[0033] Embodiment 1: This embodiment is a volute type water diversion chamber annular jet pump. Among them, fluid A is the working fluid, which enters from the inlet pipe 1; fluid B is the sucked fluid, which enters from the inlet pipe 2. The structure at the nozzle is as attached Figure 4 shown. When the working fluid A passes through the volute-type water diversion chamber, its frontal impact with the wall is relieved due to its drainage effect, and the flow parameters such as mass flow rate, velocity, and pressure of the fluid on the circular section of the working fluid transition pipe are distributed. Uniformity, suppressing the adverse effects caused by flow asymmetry, greatly improving the internal flow of the jet pump and increasing the efficiency. In addition, due to the function of the volute-type water diversion chamber, the working fluid A flows forward in a spiral shape, which is easier to mix with the sucked fluid B, and the length of the throat can be reduced...

Embodiment 2

[0034]Embodiment 2: This embodiment is a volute type water diversion chamber center jet pump. Among them, fluid A is the sucked fluid, which enters from the inlet pipe 1; fluid B is the working fluid, which enters from the inlet pipe 2. The structure at the nozzle is as attached Figure 5 shown. When the sucked fluid A passes through the volute-type water diversion chamber, its frontal impact with the wall is relieved due to its drainage effect, and the mass flow rate, velocity, pressure, etc. of the fluid flow on the circular section of the sucked fluid transition pipe The parameters are evenly distributed, which suppresses the adverse effects caused by flow asymmetry, greatly improves the internal flow of the jet pump, and improves the efficiency. In addition, due to the function of the volute-type water diversion chamber, the sucked fluid A flows forward in a spiral shape, which is easier to mix with the working fluid B, and the length of the throat can be reduced by 20%-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com