Wall and floor shoveling machine

A ground machine and casing technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of uneven removal surface, affecting work efficiency and progress, and high cost, so as to achieve a clean and smooth grinding surface and lower temperature of the cutter head , Large cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

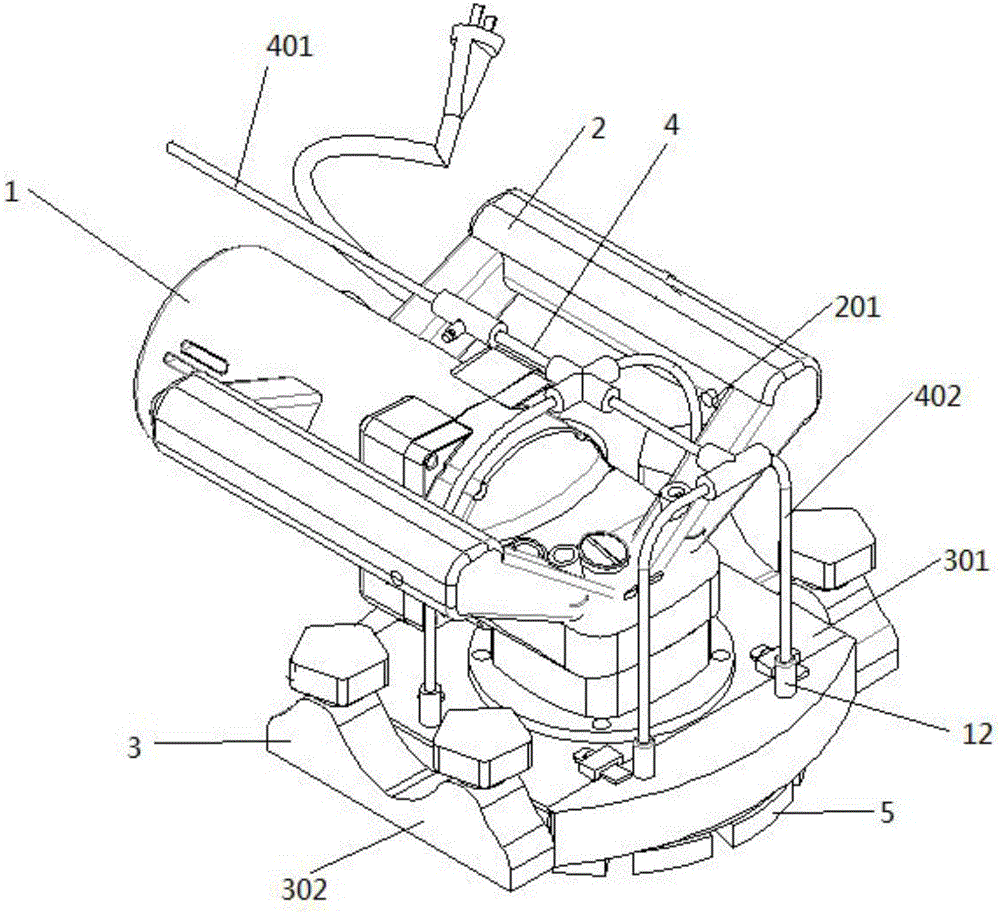

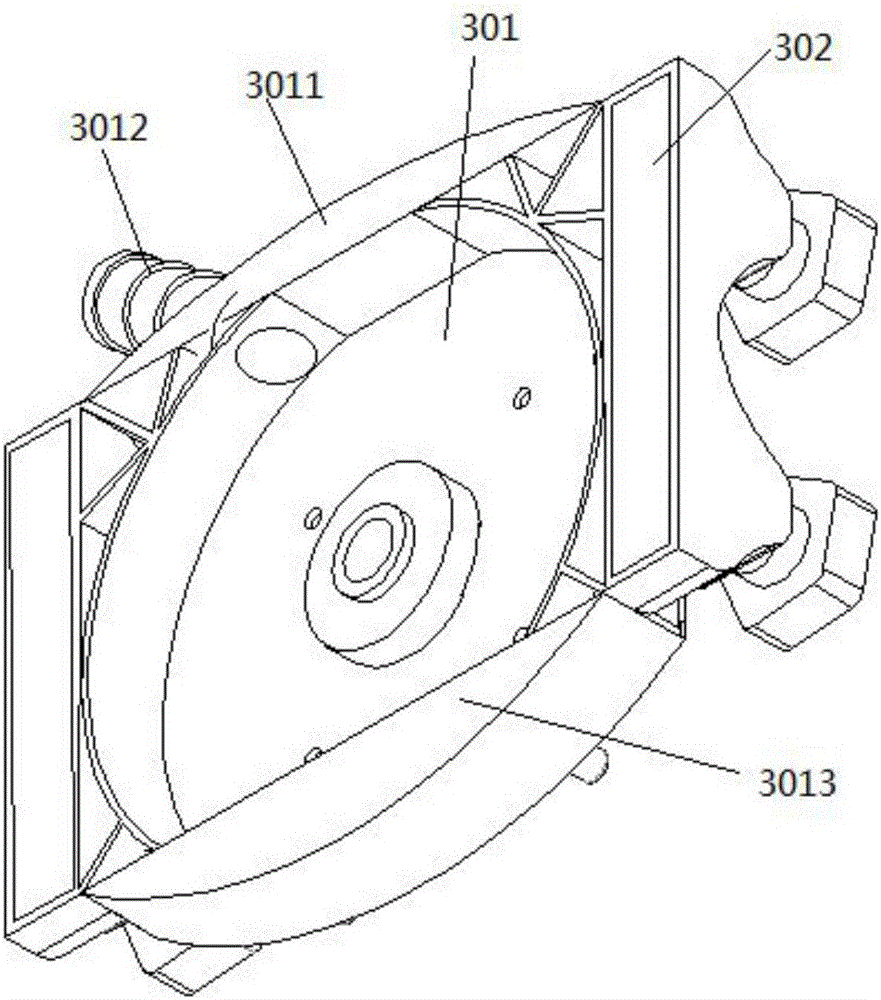

[0028] See attached figure 1 , 2 , 3, 4, 5, 6 and 7, a ground shoveling machine, comprising a casing 1, a handle 2, a dust-free depth adjustment cover 3, a water spray device 4 and a cutter 5, and a motor is installed inside the casing 1 (Installed inside, not shown in the figure), the rotating shaft of the motor is connected with the cutter 5 through the drive shaft, two handles 2 are fixed on the top of the casing 1, the casing 1 and the two handles 2 are integrally cast, and the two handles 2 Control switch 201 is respectively arranged on the top, and the start and stop of the motor can be controlled by the control switch 201. When in use, the control switch 201 on the two handles 2 must be pressed at the same time to start and close the motor, which can greatly improve the stability and stability of the work. Safety, can effectively prevent safety accidents; the dust-free depth adjustment cover 3 is installed on the bottom of the casing 1, and the dust-free depth adjustme...

Embodiment 2

[0038] See attached figure 1 , 2 , 3, 4 and 8, a multifunctional wall and floor grinding machine, the structure is the same except that the cutter head is different from that of embodiment 1, and the other structures are the same, wherein, the cutter head 502 of the present embodiment 2 includes a cuboid cutter head 5021 and a trapezoidal cutter Head 5022, cuboid cutter head 5021 and trapezoidal cutter head 50223 are arranged at intervals on the outer arc surface of disc-shaped knife holder 501, the grinding edge of the cuboid cutter head 5021 is convex, and the The grinding edge is concave. Effective heat dissipation makes diamond cutting sharper and faster, leaving no dead angle during grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com