Cotton pushing device for full-automatic cotton chopping machine

A cotton cutting machine, fully automatic technology, applied in the direction of fiber opening and cleaning machines, etc., can solve the problems of inaccurate positioning and movement of the cotton pushing mechanism and roller, and affect the quality of cotton cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

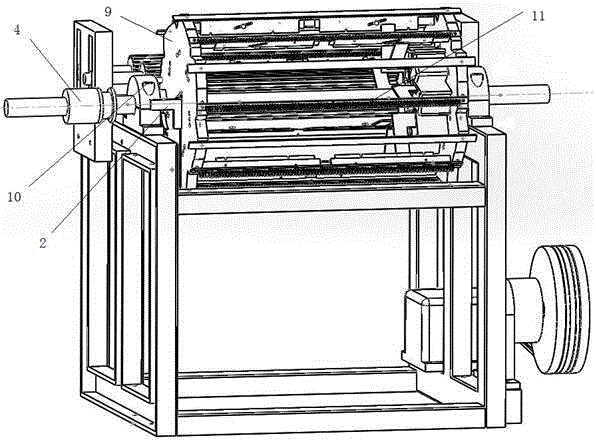

[0016] The invention provides a cotton pushing device for a fully automatic cotton cutting machine, which improves the structure of the outer grooved wheel of the existing cotton cutting machine, so that it can smoothly realize the precise positioning and movement of the cotton pushing mechanism and the roller, thereby indirectly improving the cutting efficiency. Cotton cutting quality of the cotton machine.

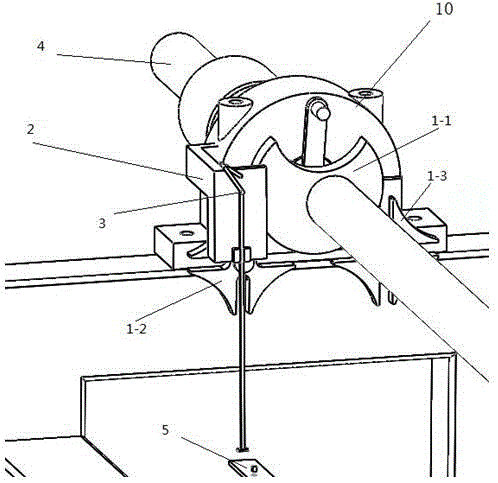

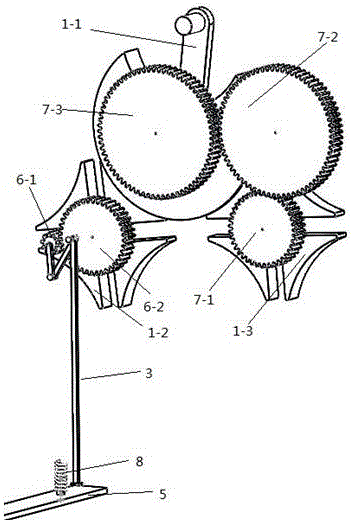

[0017] As an embodiment of the present invention, the present invention provides a cotton pushing device for a fully automatic cotton cutter, which includes a composite sheave and gear mechanism, a crank connecting rod mechanism mounting bracket 2, a crank connecting rod mechanism 3, a cotton pushing plate 5 and Compression spring 8, the central axis 4 of the cotton cutting machine is on one side of a cotton cutting drum rotating shaft sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com