Alternating soft and hard composite coating for bearing material surface and preparation method thereof

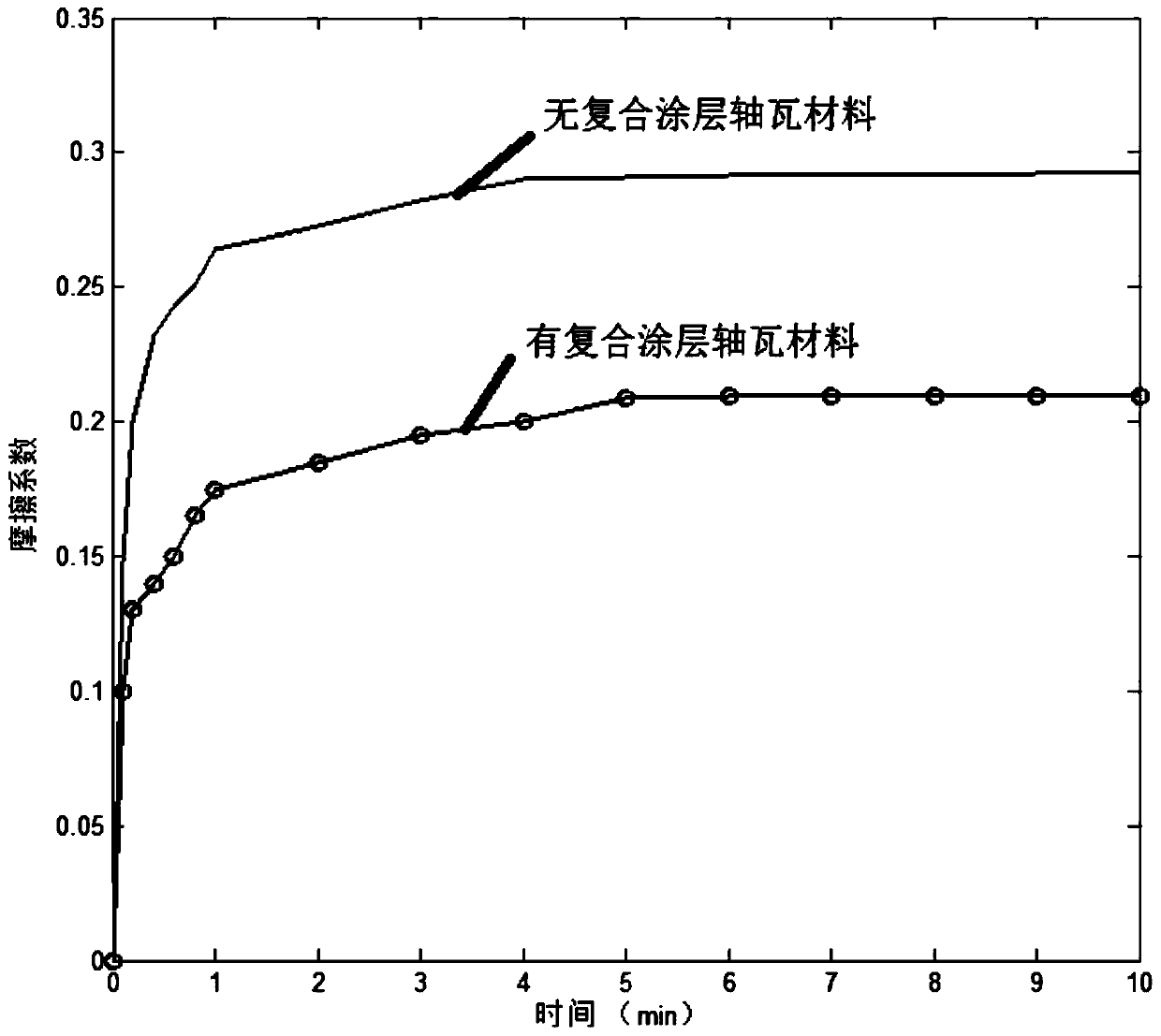

A composite coating and bearing pad technology, applied in the field of metal surface engineering, to achieve the effects of improving the bearing capacity of bearing pads, improving wear resistance and anti-friction performance, improving working life and anti-lock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a soft and hard composite coating for the surface of the bearing material, such as figure 1 As shown, it includes Cu coating, WC coating and MoS which are sequentially arranged outward from the surface of the bearing material. 2 coating. The thickness of the Cu coating is 15-50 μm, the thickness of the WC coating is 15-50 μm, and the MoS 2 The coating thickness is 15-50 μm. The total thickness of the composite coating is not more than 100 μm.

[0033] This embodiment also provides a method for preparing a soft and hard composite coating on the surface of the bearing material, which includes the following steps:

[0034] 1. Sand blast the inner surface of the bearing pad to make the roughness reach RZ 25-100μm. Put the sprayed bearing pad material into acetone solution for ultrasonic cleaning for 10 minutes. After cleaning, put the bearing pad material in an oven at 80°C for 30 min.

[0035] 2. Preparation of Cu soft coating by flame spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com