Oil-resistant low-temperature-resistant flame-retardant polyolefin rubber cable material and preparation method thereof

A technology of polyolefin rubber and low temperature resistance is applied in the field of oil-resistant and low-temperature flame-retardant polyolefin rubber cable material and its preparation. The effect of electric energy and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

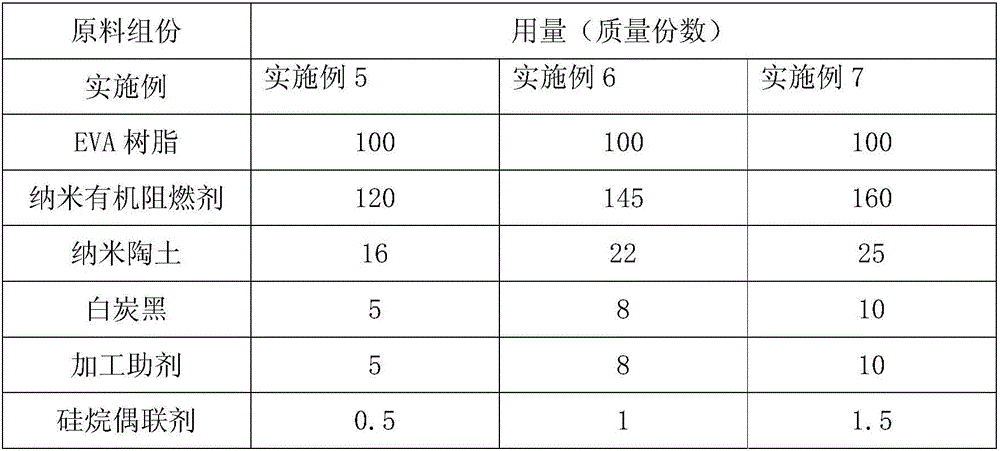

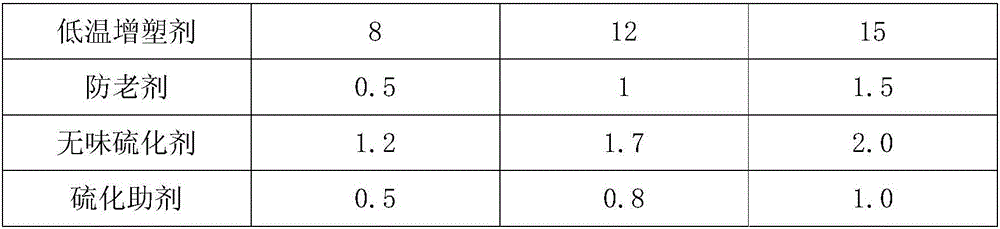

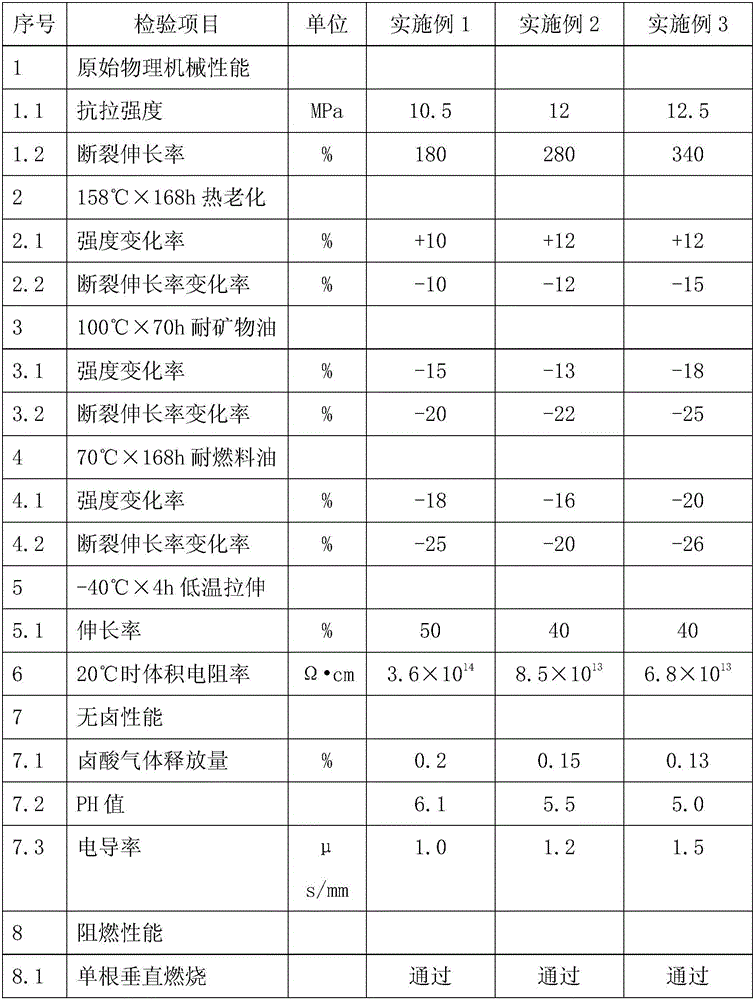

Embodiment 1

[0031] A 125°C chemically cross-linked oil-resistant, low-temperature, and flame-retardant polyolefin rubber cable material, which consists of 100 parts by weight of EVA resin, 50 nano-scale organic flame retardants, nano-aluminum hydroxide, 50 magnesium hydroxide, and 5 white carbon black. , Nano clay kaolin 15, processing aid zinc stearate 5, Dow Corning silane coupling agent A-172 1, low temperature plasticizer dioctyl sebacate 5 and 168 plasticizer 3, antiaging agent 2246S 0.5, peroxide Compound vulcanizing agent 1.2, vulcanization aid triallyl isocyanurate 0.5. Nano organic flame retardant combined with nano aluminum hydroxide and magnesium hydroxide, the surface is treated with silane coupling agent.

Embodiment 2

[0033] An oil-resistant, low-temperature, and flame-retardant polyolefin rubber cable material, which consists of 100 parts by weight of EVA resin, 80 nanometer-scale organic flame retardants, nano-aluminum hydroxide and 80 magnesium hydroxide, 10 white carbon black, and 25 nano-clay kaolin. , processing aid calcium stearate 10, Dow Corning silane coupling agent A-172 2, low-temperature plasticizer dioctyl sebacate 7 and 168 plasticizer 7, antioxidant 2246S 1.5, peroxide vulcanizing agent 2, Vulcanization aid triallyl isocyanurate 1. Nano organic flame retardant combined with nano aluminum hydroxide and magnesium hydroxide, the surface is treated with silane coupling agent.

Embodiment 3

[0035] Embodiment 1 The preparation method of oil-resistant and low-temperature flame-retardant polyolefin rubber cable material, its preparation process is as follows:

[0036] 1) Mastication

[0037] Plasticize the EVA resin particles in the internal mixer alone for 5 minutes, then roll them down and let them stand for 24 hours before they can be used; when the temperature on the internal mixer reaches 60°C, turn on the cooling water of the internal mixer for cooling;

[0038] 2) Mixing

[0039] The plasticized EVA resin is put into banburying for plastication, and the time is controlled at 0.5min;

[0040] Add processing aids, silane coupling agent, nano-clay and white carbon black, and the mixing time is 4 minutes;

[0041] Add nano-organic flame retardant, low-temperature plasticizer, anti-aging agent, odorless vulcanizing agent, and vulcanization aid. When adding nano-organic flame retardant, add nano-organic flame retardant one bag at a time, the time interval is 1min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com