Polycarboxylate superplasticizer containing phosphate groups and preparation method

A technology of water reducer and polycarboxylic acid, which is applied in the field of polycarboxylate water reducer and its preparation, and achieves the effects of simple preparation method, low energy consumption and good slump performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

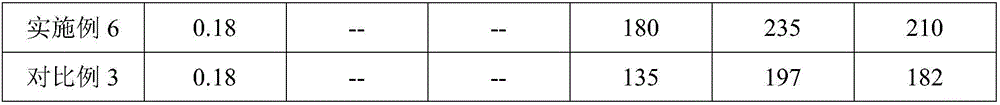

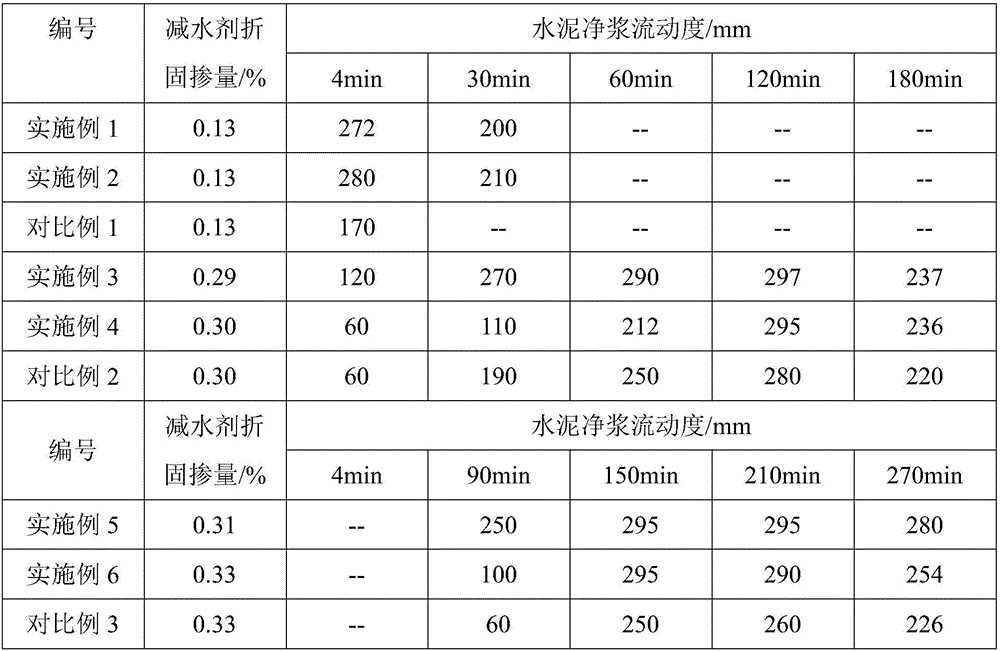

Examples

Embodiment 1

[0023] Add 75 parts of allyl polyoxyethylene ether (HPEG-2400) into the four-neck flask, stir and dissolve 52.5 parts of water, and heat up to 20°C. After the allyl polyoxyethylene ether is completely dissolved, add 0.23 parts Sodium phosphate, stir to dissolve, then add 0.98 parts of sodium hypophosphite, keep warm for 10 minutes after the solid is completely dissolved, add 0.7 parts (mass concentration: 30%) of hydrogen peroxide, stir for 5 minutes, and drop the pre-configured feed solution at the same time A, material liquid B; wherein material liquid A is formed by mixing 10 parts of acrylic acid and 9.5 parts of water, and the dropping time is 3 hours, and material liquid B is formed by mixing and dissolving 0.2 parts of L-ascorbic acid and 22.5 parts of water into, the dropping time is 3.5h. After the dropwise addition of the two materials is completed, the temperature is kept at the final temperature for 1 to 1.5 hours, and the pH is adjusted to 7±1 with 32% sodium hydr...

Embodiment 2

[0025] Add 75 parts of isopentenol polyoxyethylene ether (TPEG-2400) into the four-neck flask, stir and dissolve 52.5 parts of water, and heat up to 20°C. After the polyether is completely dissolved, add 0.23 parts of sodium phosphate, Stir to dissolve, then add 0.98 parts of sodium hypophosphite, after the solid dissolves completely, add 0.7 parts (mass concentration: 30%) of hydrogen peroxide, stir for 5 minutes, and drop the pre-configured feed liquid A and feed liquid B at the same time; Wherein feed liquid A is formed by mixing 8.7 parts of acrylic acid and 9.5 parts of water, and the dropping time is 3 hours; feed liquid B is formed by mixing and dissolving 0.2 parts of L-ascorbic acid and 22.5 parts of water, and the dropping time is 3.5h. After the dropwise addition of the two materials is completed, the temperature is kept at the final temperature for 1 to 1.5 hours, and the pH is adjusted to 7±1 with 32% sodium hydroxide solution to obtain the polycarboxylate water r...

Embodiment 3

[0029] Add 75 parts of isopentenol polyoxyethylene ether (TPEG-2400) into the four-neck flask, stir and dissolve 70 parts of water, and heat up to 25°C. After the polyether is completely dissolved, add 0.2 parts of sodium phosphate, Stir to dissolve, then add 0.87 parts of sodium hypophosphite, after the solid dissolves completely, add 1 part (mass concentration: 30%) of hydrogen peroxide, stir for 5 minutes, and drop the pre-configured feed liquid A and feed liquid B at the same time; Wherein feed liquid A is to be formed by mixing 6 parts of acrylic acid, 11.8 parts of hydroxyethyl acrylate and 28 parts of water, and the dropping time is 2.5 hours; feed liquid B is made of 0.16 parts of L-ascorbic acid and 25.8 parts of water It is formed by mixing and dissolving, and the dropping time is 3h. After the dropwise addition of the two materials is completed, the temperature is kept at the final temperature for 1 to 1.5 hours, and the pH is adjusted to 7±1 with 32% sodium hydroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com