Improvement fertilizer for plantation of vines in saline land and improvement method thereof

A saline-alkali land and rattan technology, which is applied in the saline-alkali land rattan planting improvement fertilizer and its improvement field, can solve the problems of cumbersome saline-alkali land improvement methods, affecting the progress of soil transformation, and complex improver formulations, achieving good improvement effects, low production costs, The effect of increasing the pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

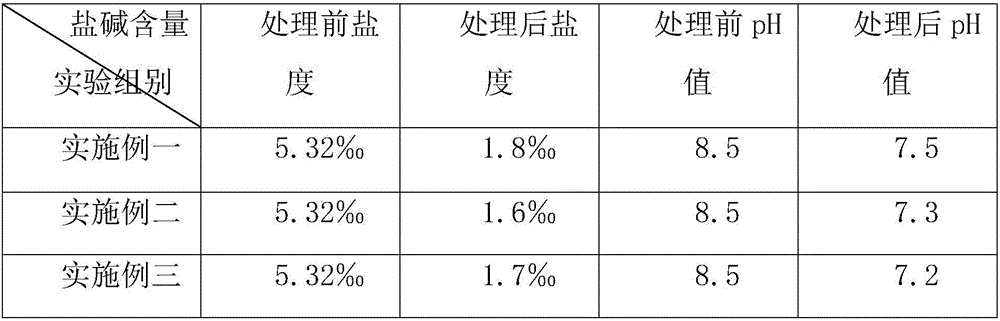

Embodiment 1

[0019] The invention provides a technical solution: an improved fertilizer for vine planting in saline-alkali land, the improver includes the following raw materials by weight: 50 parts of crop straw gypsum urea powder, 40 parts of dried livestock manure, 35 parts of yellow mud powder, superphosphoric acid 50 parts of calcium, 30 parts of ammonium chloride, 45 parts of pine needle soil, 50 parts of diammonium phosphate.

[0020] Wherein, the dry livestock manure is one or a mixture of horse manure, cow manure, sheep manure, chicken manure, and pig manure, and the dry livestock manure needs to be stirred, fermented, dehydrated, dried, deodorized, It is produced through the process steps of crushing.

[0021] Wherein, for the crop straw gypsum urea powder, the crop straw is firstly removed from impurities, then dried, and then crushed to a fiber length of 5-10 mm, and then the gypsum powder and urea are stirred, that is It can be used as an ingredient of improver.

[0022] Whe...

Embodiment 2

[0029] The invention provides a technical solution: an improved fertilizer for vine planting in saline-alkali land, the improver includes the following raw materials by weight: 70 parts of crop straw gypsum urea powder, 60 parts of dried livestock manure, 65 parts of yellow mud powder, superphosphoric acid 60 parts of calcium, 50 parts of ammonium chloride, 55 parts of pine needle soil, 60 parts of diammonium phosphate.

[0030] Wherein, the dry livestock manure is one or a mixture of horse manure, cow manure, sheep manure, chicken manure, and pig manure, and the dry livestock manure needs to be stirred, fermented, dehydrated, dried, deodorized, It is produced through the process steps of crushing.

[0031] Wherein, for the crop straw gypsum urea powder, the crop straw is firstly removed from impurities, then dried, and then crushed to a fiber length of 5-10 mm, and then the gypsum powder and urea are stirred, that is It can be used as an ingredient of improver.

[0032] Whe...

Embodiment 3

[0039] The invention provides a technical solution: an improved fertilizer for vine planting in saline-alkali land, the improver includes the following raw materials by weight: 62 parts of crop straw gypsum urea powder, 51 parts of dried livestock manure, 47 parts of yellow mud powder, superphosphoric acid 56 parts of calcium, 41 parts of ammonium chloride, 52 parts of pine needle soil, 54 parts of diammonium phosphate.

[0040] Wherein, the dry livestock manure is one or a mixture of horse manure, cow manure, sheep manure, chicken manure, and pig manure, and the dry livestock manure needs to be stirred, fermented, dehydrated, dried, deodorized, It is produced through the process steps of crushing.

[0041]Wherein, for the crop straw gypsum urea powder, the crop straw is firstly removed from impurities, then dried, and then crushed to a fiber length of 5-10 mm, and then the gypsum powder and urea are stirred, that is It can be used as an ingredient of improver.

[0042] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com