Packaging tray for liquid crystal display panel and extensible and retractable unit pieces constituting packaging tray

A liquid crystal panel, retractable technology, applied in the field of retractable monomers, can solve the problems of increased difficulty in placing sheets in automatic packaging equipment, affecting packaging quality, and inaccurate placement of sheets, so as to avoid glass damage and damage , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

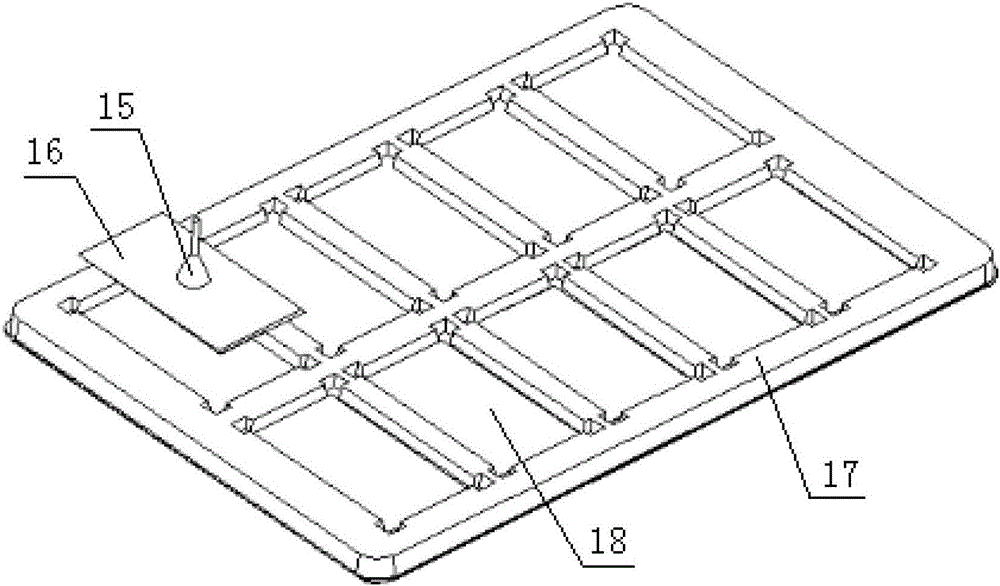

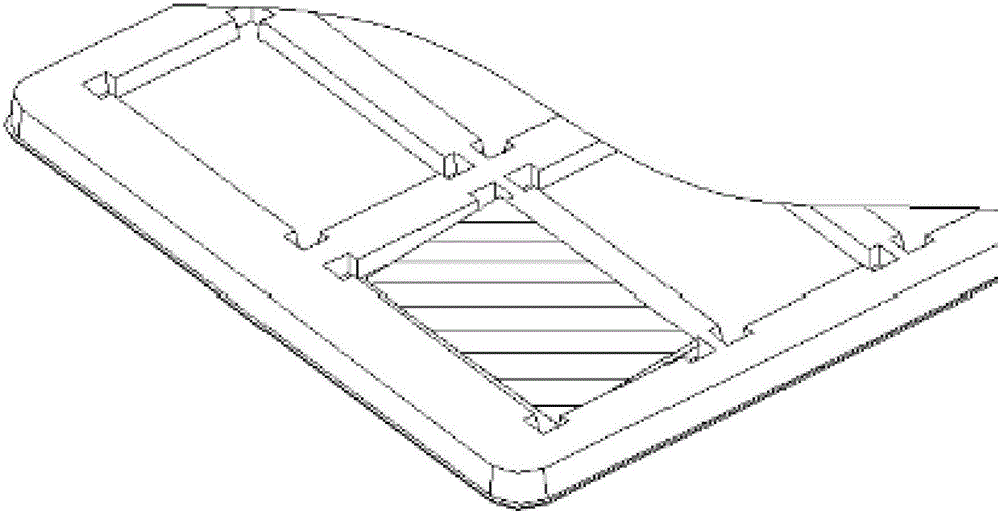

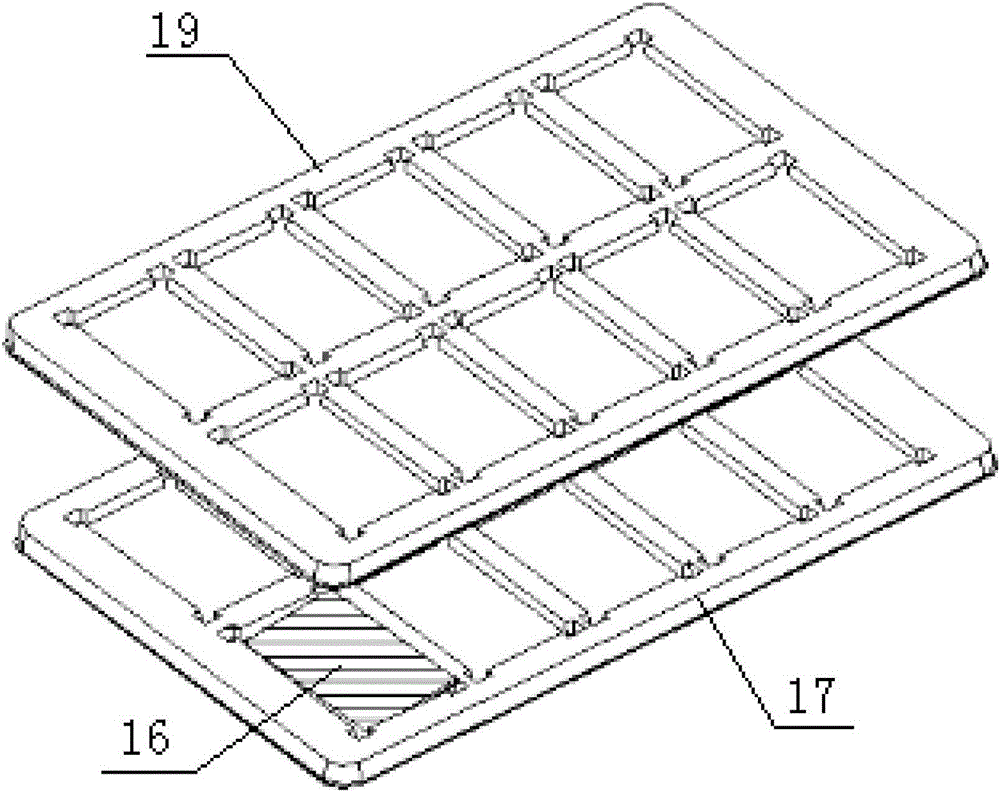

[0032] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 Describe this embodiment, this embodiment includes several telescopic monomers 1, several telescopic monomers 1 are arranged in a rectangular array, and several telescopic monomers 1 are fixedly connected in turn to form a pallet body as a whole, each telescopic The monomer 1 includes a base plate 2 and four edges 3, the base plate 2 is arranged horizontally and its top view shape is a quadrangle, and the four edges 3 are arranged in sequence along the periphery of the base plate 2 and outward in a direction perpendicular to the base plate 2 protruding, and each edge 3 is fixedly connected to an edge of the bottom plate 2, each edge 3 is a telescopic edge, and adjacent telescopic monomers 1 are spaced apart by the edge 3, and each telescopic One glass substrate 4 can be accommodated in the single body 1 .

[0033] I...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment is a further limitation of Embodiment 1. In this embodiment, the four edges 3 in each telescopic monomer 1 include two transverse edges 5 and two longitudinal edges 6, The transverse edge 5 is arranged along the length direction of its base plate 2, and the longitudinal edge 6 is arranged along the width direction of its base plate 2. The structures of the transverse edge 5 and the longitudinal edge 6 are identical, and each transverse edge 5 includes a first The elastic middle section 5-1 and two first fixed end portions 5-2, the two ends of the first elastic middle section 5-1 are respectively fixedly connected with a first fixed end portion 5-2; each longitudinal edge 6 includes The second elastic middle section 6-1 and two second fixed end portions 6-2, two ends of the second elastic middle section 6-1 are respectively fixedly connected with a second fixed end portion 6-2.

specific Embodiment approach 3

[0036] Specific Embodiment 3: This embodiment is a further limitation of Specific Embodiment 2. In this embodiment, the bottom plate 2 in each telescopic monomer 1 is a telescopic plate body, and the bottom plate 2 in each telescopic monomer 1 includes The transverse elastic slats 7, the longitudinal elastic slats 8 and the four fixing plates 9, the transverse elastic slats 7, the longitudinal elastic slats 8 and the four fixing plates 9 are on the same plane and are sequentially fixed and connected as one. The longitudinal directions of the transverse elastic slats 7 and the longitudinal elastic slats 8 are perpendicular to each other, and the two ends of the transverse elastic slats 7 in the longitudinal direction and the two second elastic middle sections 6- 1 is fixedly connected, the two ends of the length direction of the longitudinal elastic slats 8 are fixedly connected with the two first elastic middle sections 5-1 in the telescopic monomer 1, the transverse elastic sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com