Tipping paper perforating device

A technology of punching device and tipping paper, applied in the field of tipping paper manufacturing, can solve the problems of not easily piercing the bronzing layer, unable to punch out, unable to work normally, etc., and achieve the effect of avoiding visible burning traces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

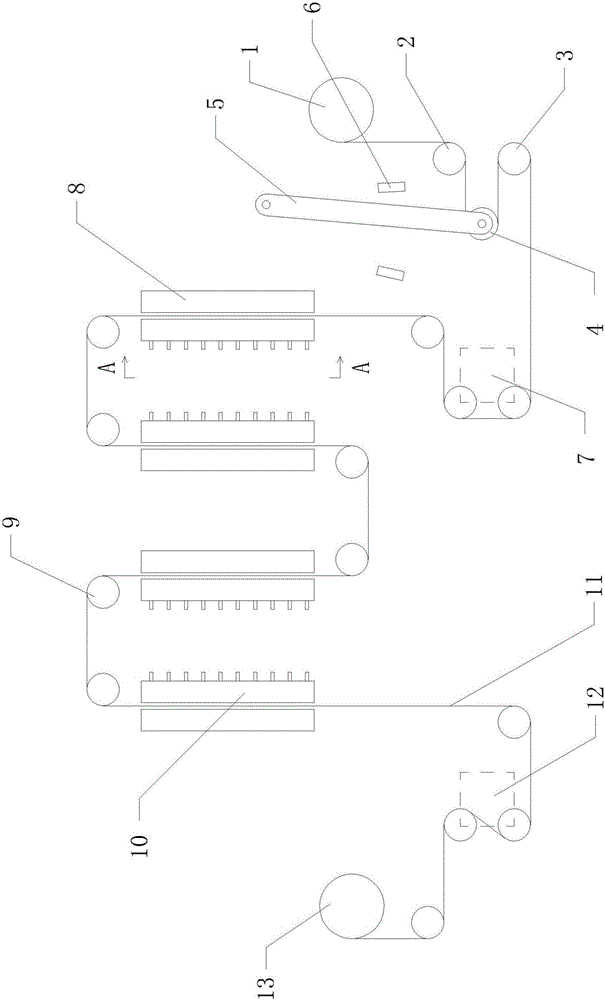

[0034] Such as figure 1 , 4 As shown, the tipping paper punching device includes a paper feeding wheel 1, a delivery wheel 13, a punching plate 10, and a back plate 8, and there is a gap between the punching plate 10 and the back plate 8. Several plasma punching devices are arranged on the punching plate 10 . It also includes a conductive wheel 4, and the side of the conductive wheel 4 is electrically conductive. Two perforated plates 10 can be used as one group, or multiple groups can be used at the same time, and holes are punched on the edges of both sides of the tipping paper tape 11 respectively.

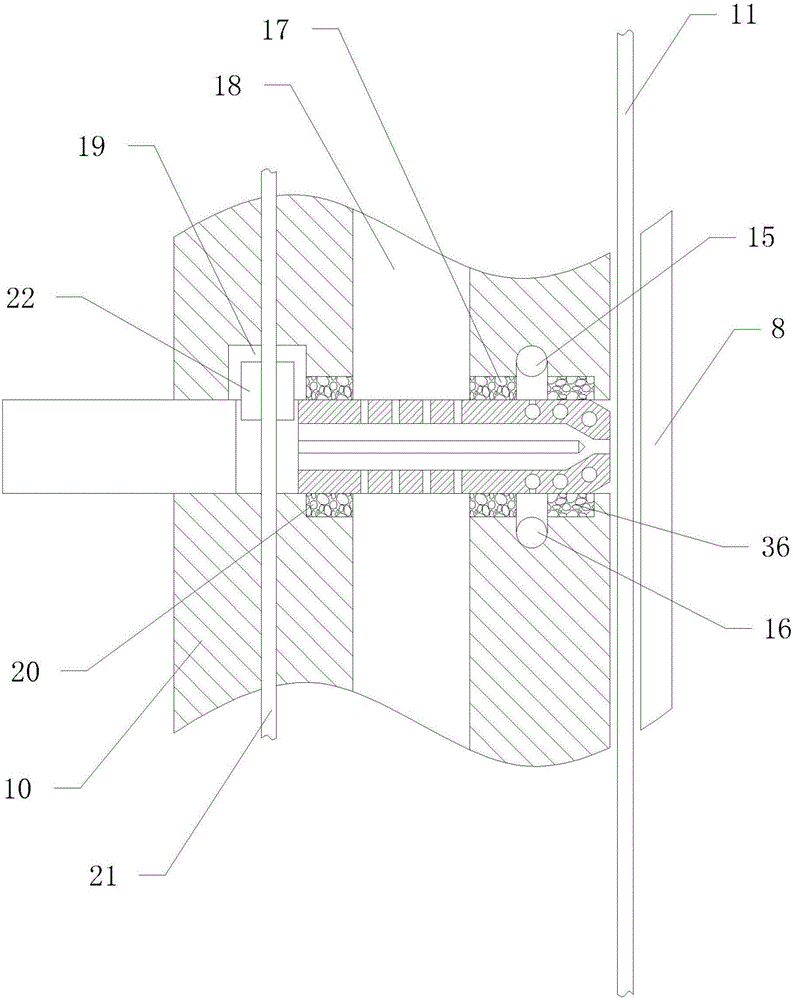

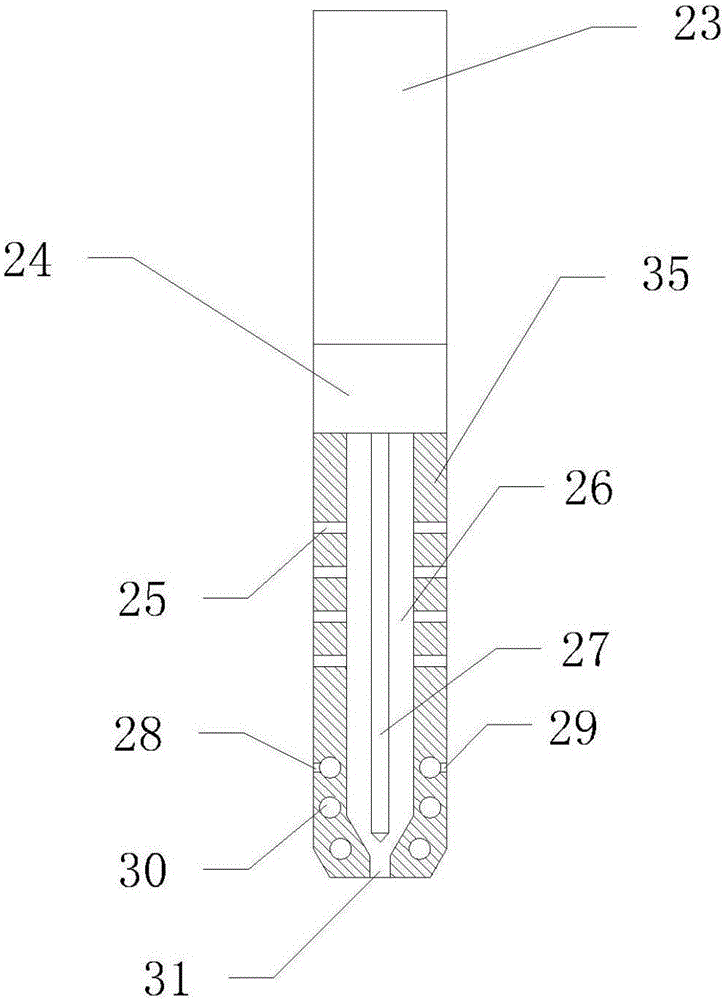

[0035] Such as figure 2 , 3 As shown, the perforated plate 10 is provided with an air pipe 18 and several installation holes 14, the installation holes 14 communicate with the air pipe 18, the ion punching device is arranged in the installation hole 14, and the plasma punching device includes a shell 35, the housing 35 is provided with a cavity 26, the side wall of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com