Light redirecting film having varying optical elements

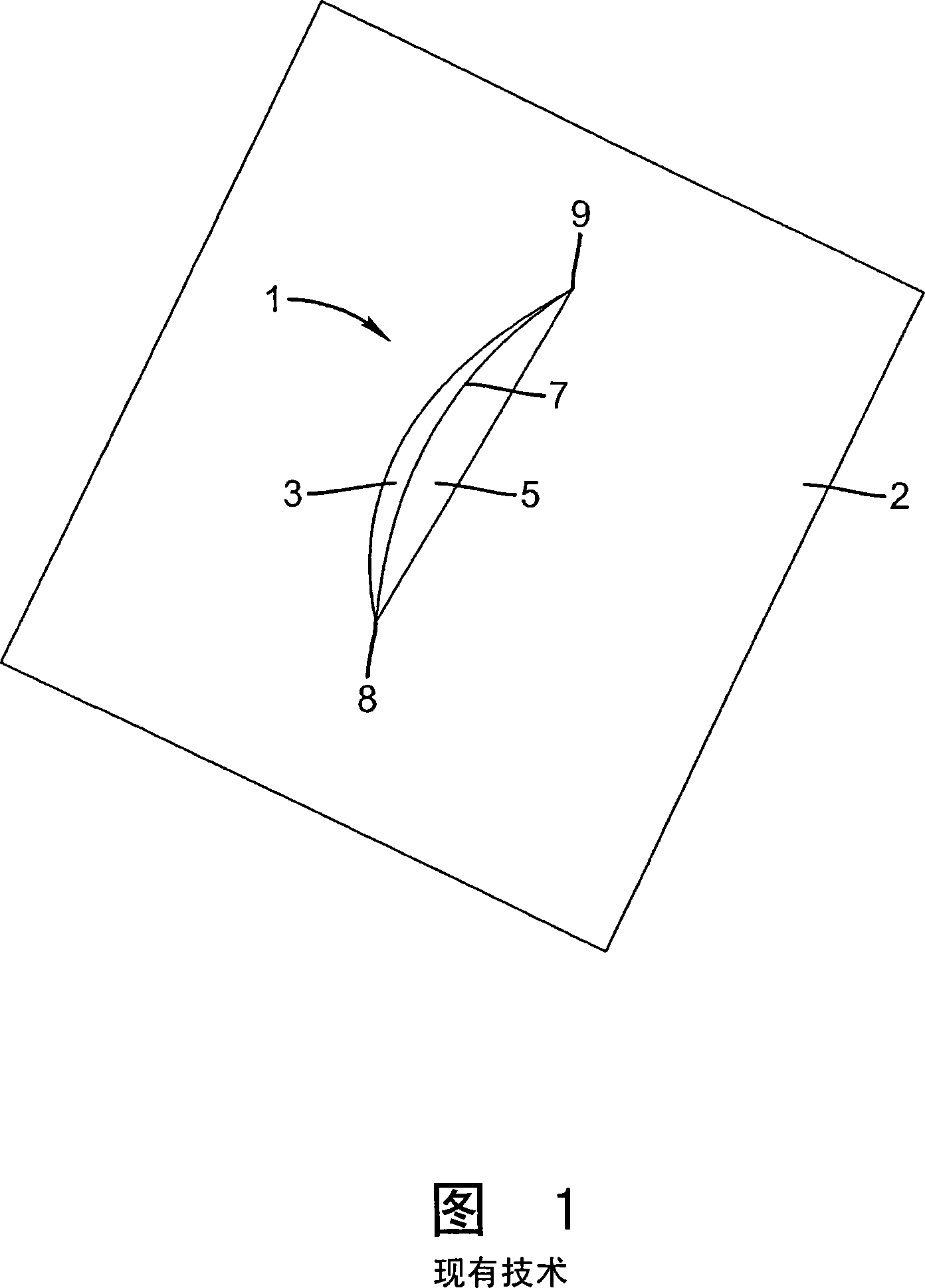

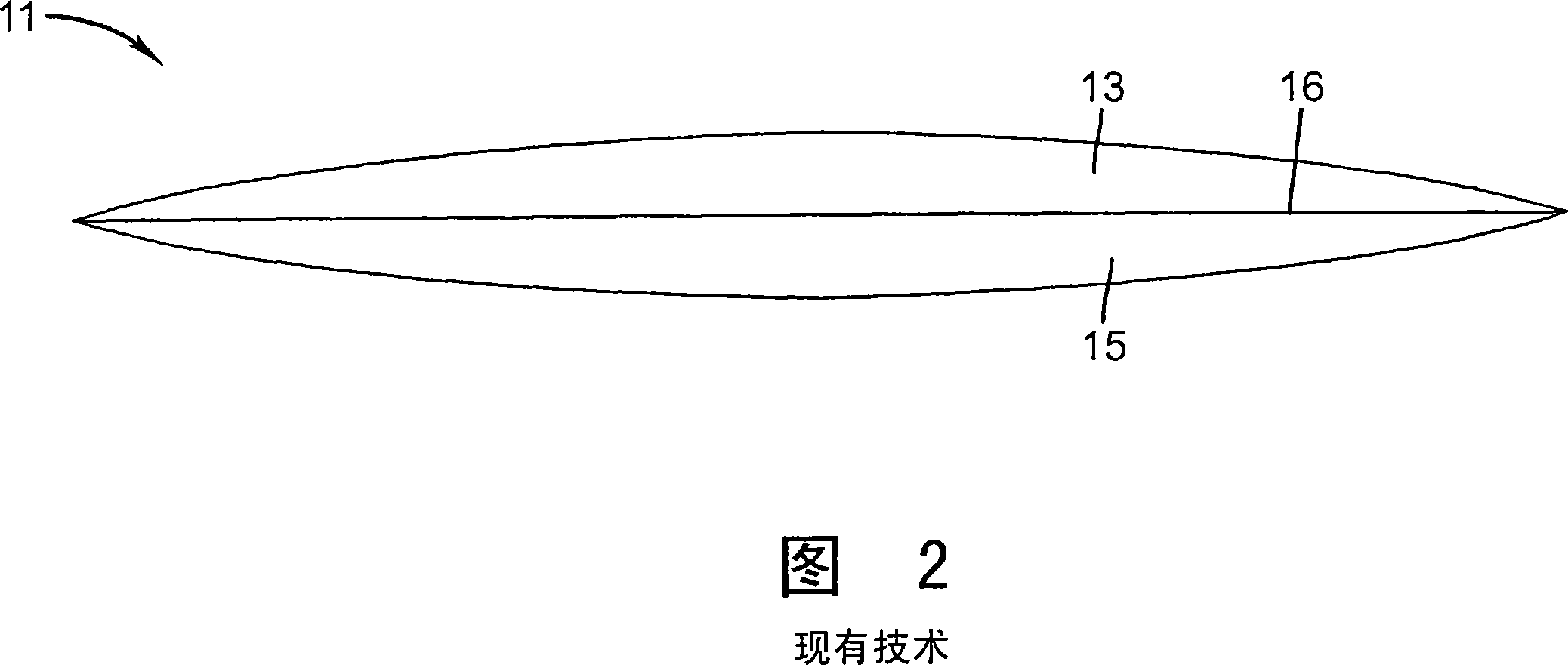

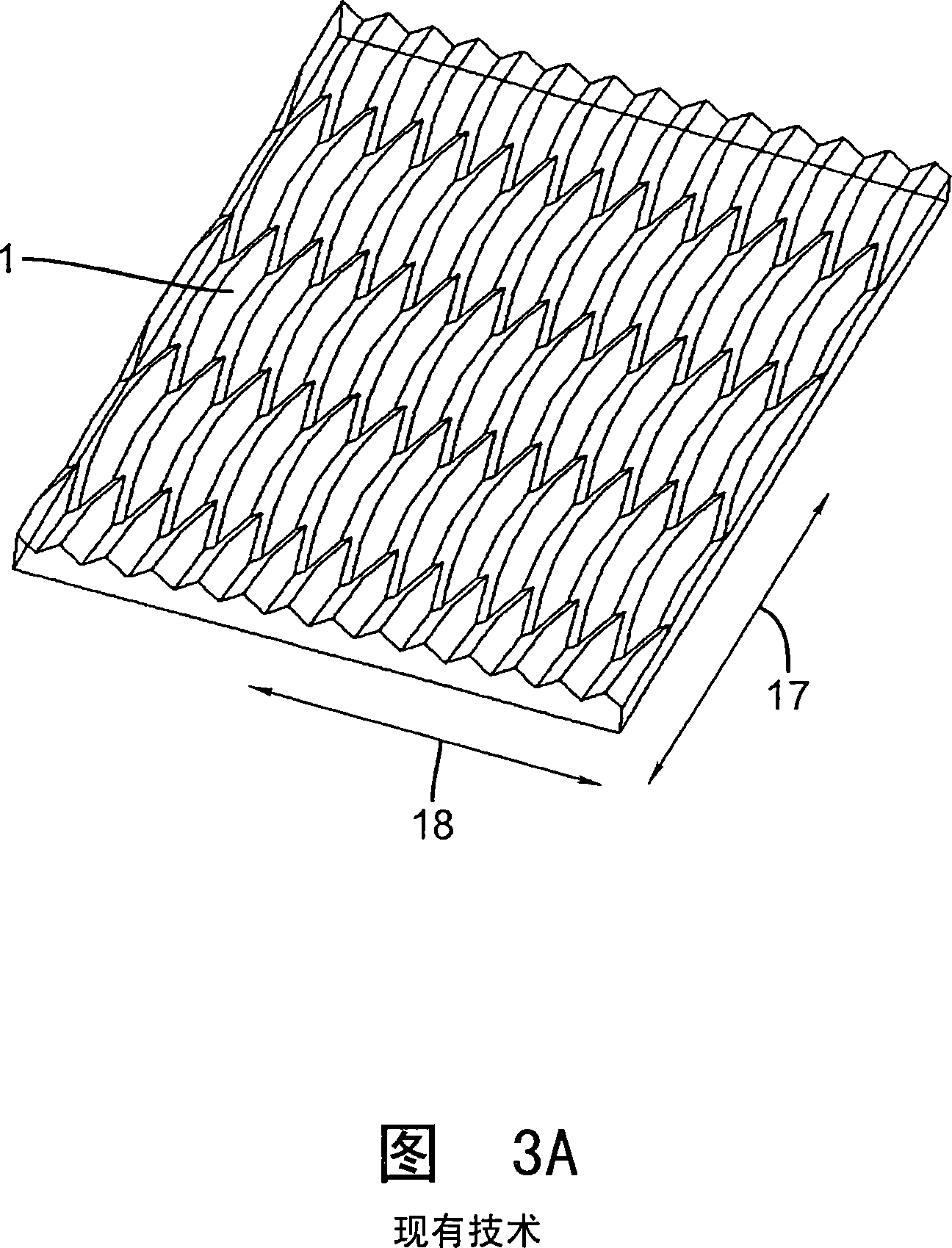

一种光重新定向、光学元件的技术,应用在光学元件、光学、非线性光学等方向,能够解决增益变化、修饰缺陷、增益损失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention have many advantages over existing light redirecting films. The two or more size and shape distributions of the optical elements and their placement on the film produce high on-axis gain while greatly reducing moire fringes. The light redirecting films of the present invention have a diffuse or textured appearance, avoiding unwanted patterns. The various shapes of the optical elements mask cosmetic defects in and under the light redirecting film. The small portion of the optical element extending over the other elements provides spacing between the film and the contact surface to avoid optical coupling at the ridges of most elements, avoid Newton's rings and protect the ridges of most elements from damage. Films of the present invention with elements of multiple sizes provide higher on-axis gain than light redirecting films with elements of only one size. These and other advantages will become more apparent from the detailed descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com