Hot air bending rivet welding machine and welding method used in automotive exterior trimming plastic parts

A technology of plastic parts and welding methods, applied in the field of plastic welding, which can solve problems such as high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

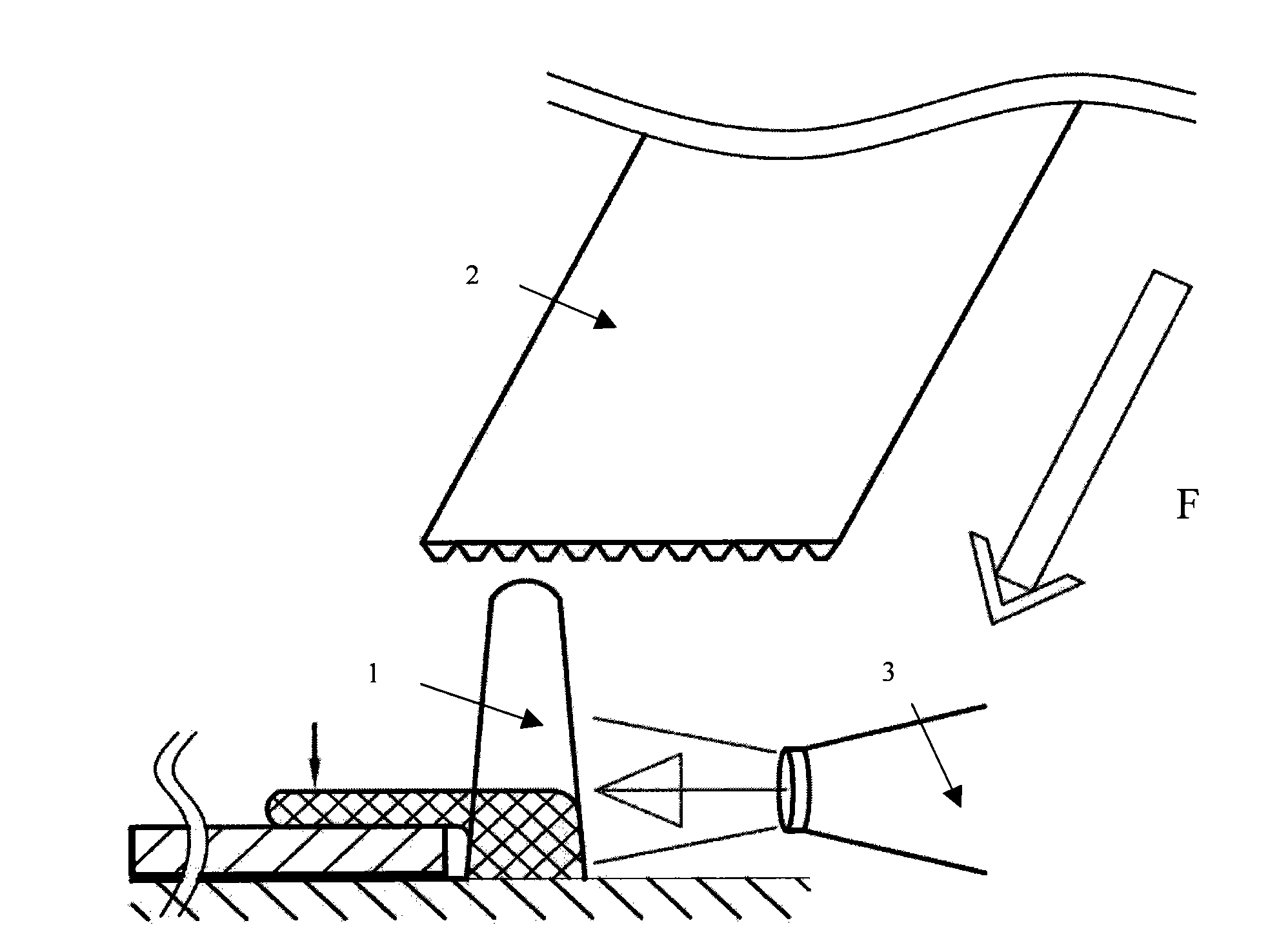

[0020] The following is based on Figure 1 to Figure 5 , the embodiments of the present invention are given, so that the functions and features of the present invention can be better understood.

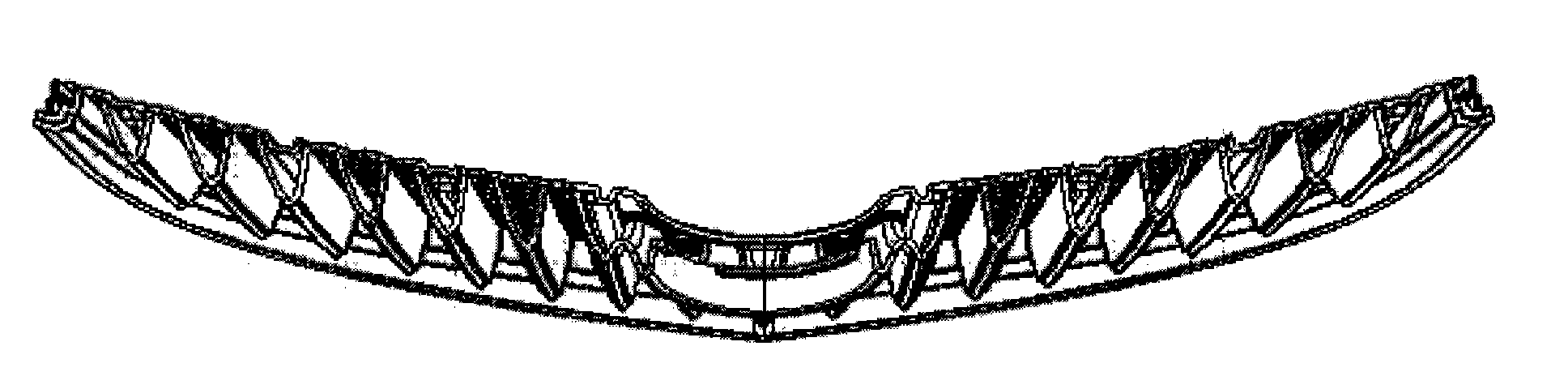

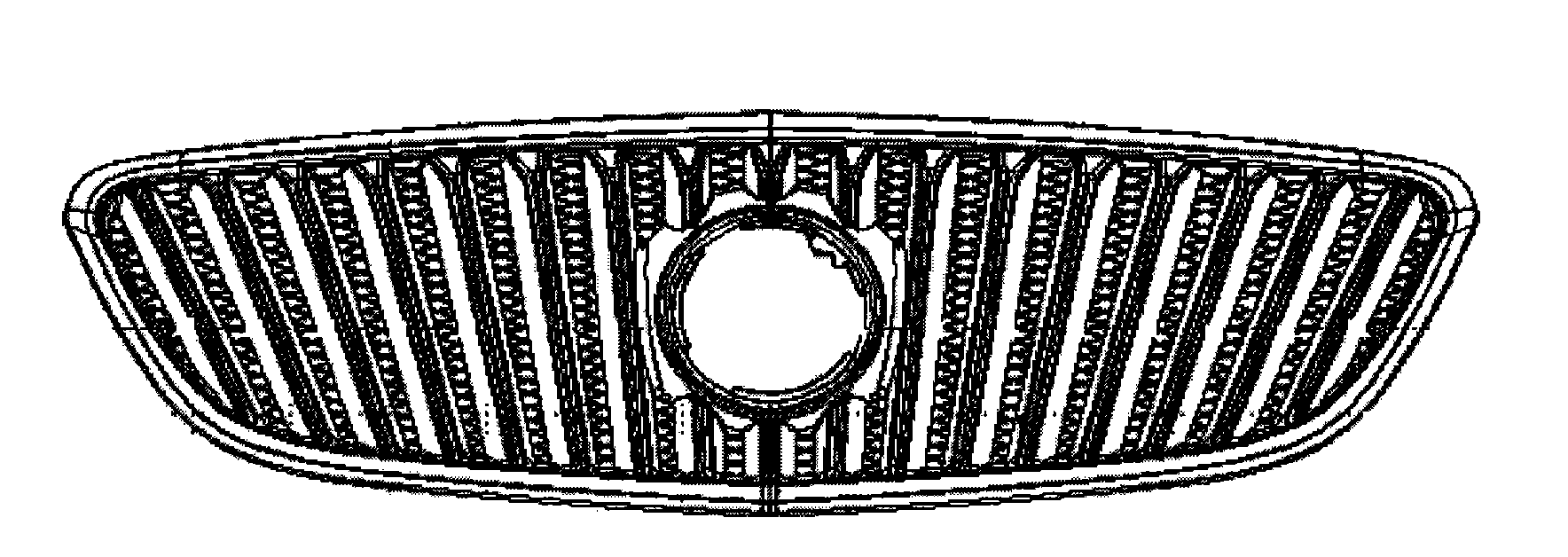

[0021] combine figure 1 with image 3 As shown, the hot air bending riveting welding machine for automobile exterior plastic parts of the present invention includes three components: a prolate welding rod 1 , a diamond-shaped welding head 2 and a blower 3 .

[0022] On non-slender parts, if the edge part needs to be connected to another part, an elongated welding rod 1 can be designed for connection, and the cross section of the elongated welding rod 1 can be in any shape.

[0023] The diamond-shaped welding head 2 is used to press down the welding rod 1 from an oblique direction F to bend the welding rod 1 to one side.

[0024] The blower 3 is used to heat the part of the welding rod 1 that needs to be bent, so that the part reaches the softening temperature of the plastic.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com