Method and device for plasma drilling of tipping paper

A technology of tipping paper and plasma, applied in plasma, plasma welding equipment, cigarette manufacturing, etc., can solve problems such as uneven hole size distribution, spark splashing, etc., achieve precise hole diameter and position, and avoid visible burning traces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below through specific examples.

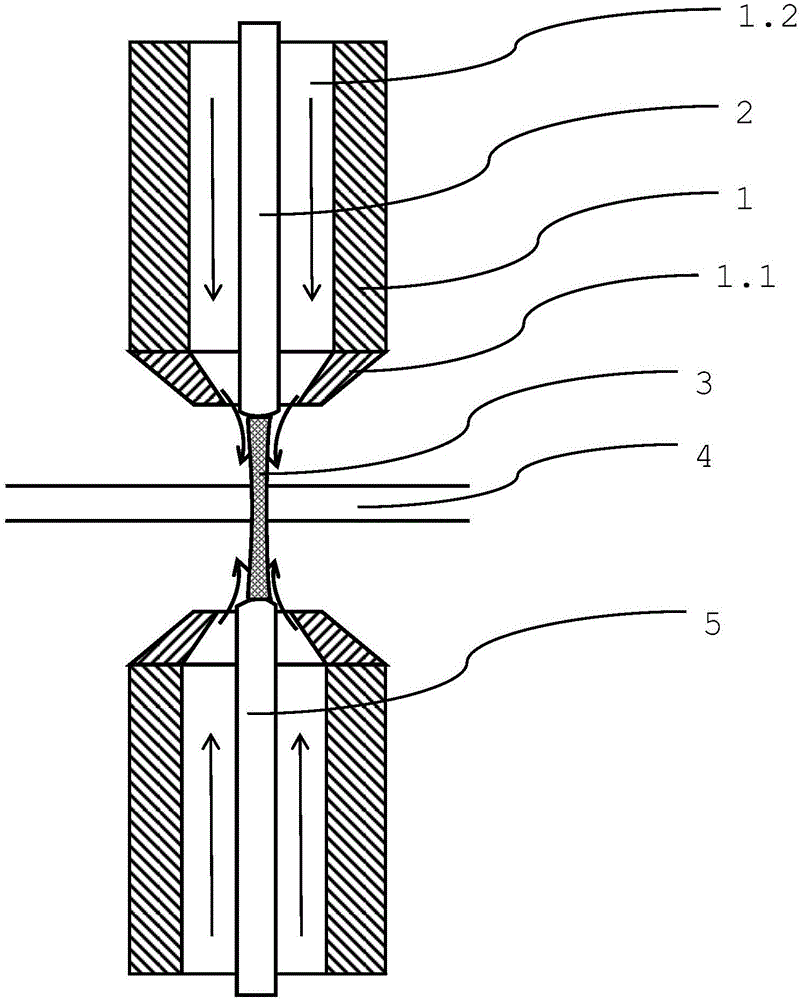

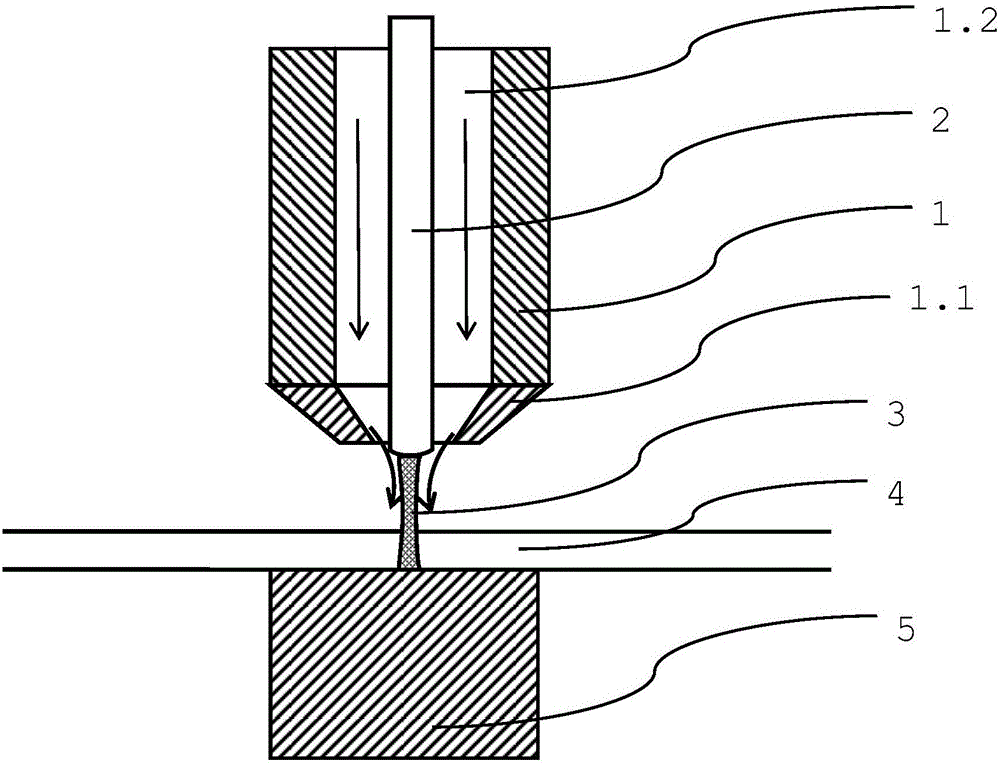

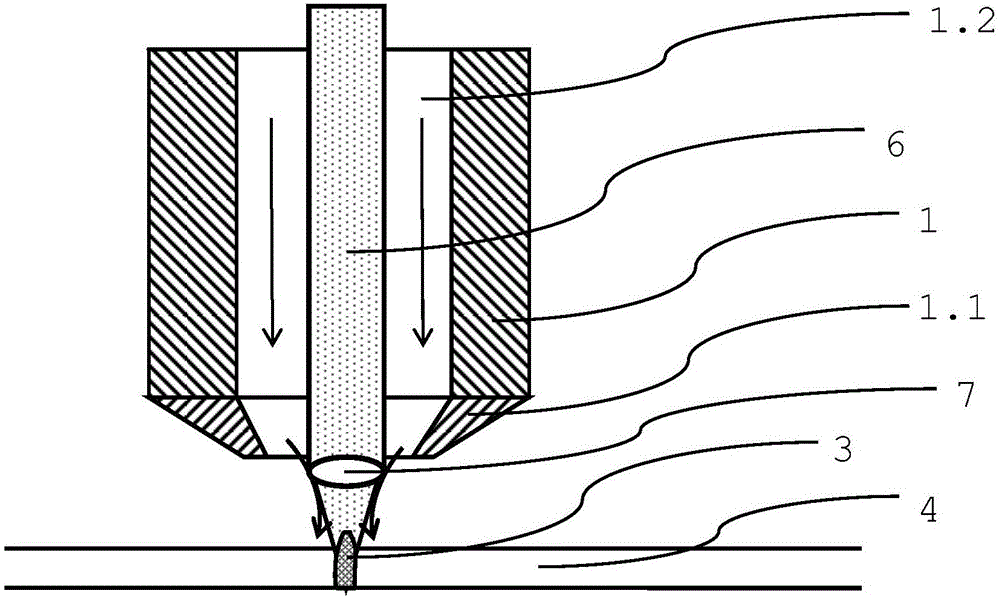

[0024] figure 1 shows an apparatus according to the invention for the plasma perforation of paper webs, in particular for the plasma perforation of tipping paper webs or tipping papers 4 . An energy source with as small an area as possible is placed on the flat side of the tipping paper 4 . In this example, a needle-shaped electrode 2 is used as an energy source, more precisely to apply a voltage between the two electrodes 2 and 5 . Electrode 2 is mounted on tube 1 . Tube 1 is used to deliver pressurized gas or gas mixture. For better understanding, the airflows in the figure are marked with arrows. At the front end of the tube 1 there is a nozzle 1.1 for narrowing the air flow. This nozzle 1.1 is mounted at its tip facing the tipping paper 4, concentrically with the electrode 2. Via the cavity 1.2 closed by the tube 1 and the nozzle 1.1, the pressurized g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com