Control system for blood taking needle assembly machine

A control system and lancet technology, applied in the field of automatic assembly machine systems, can solve the problems of low wound pain, unqualified lancets, and user safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the embodiments given in the accompanying drawings.

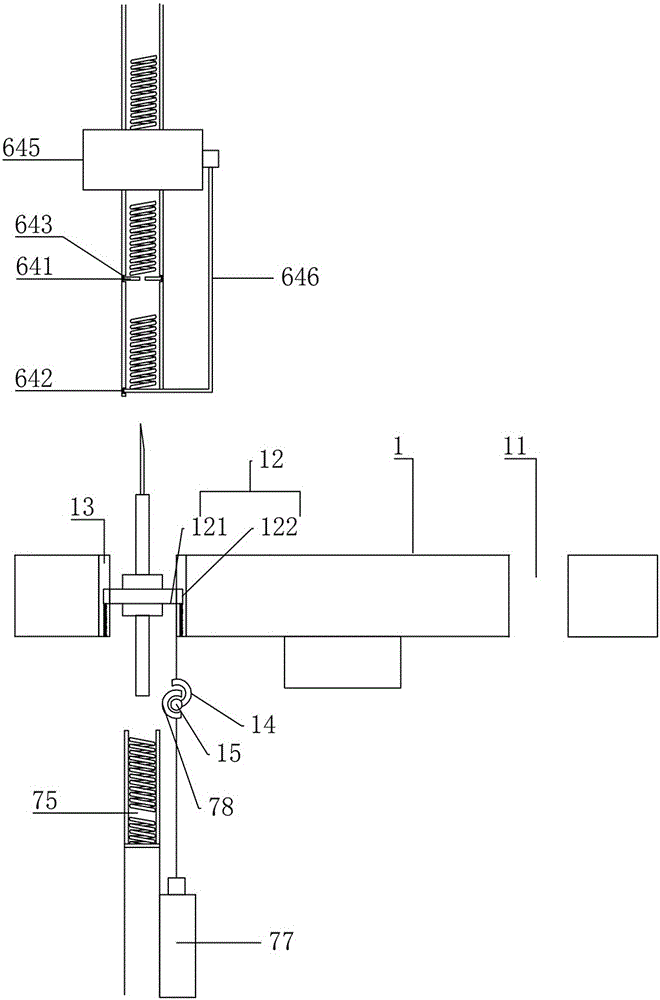

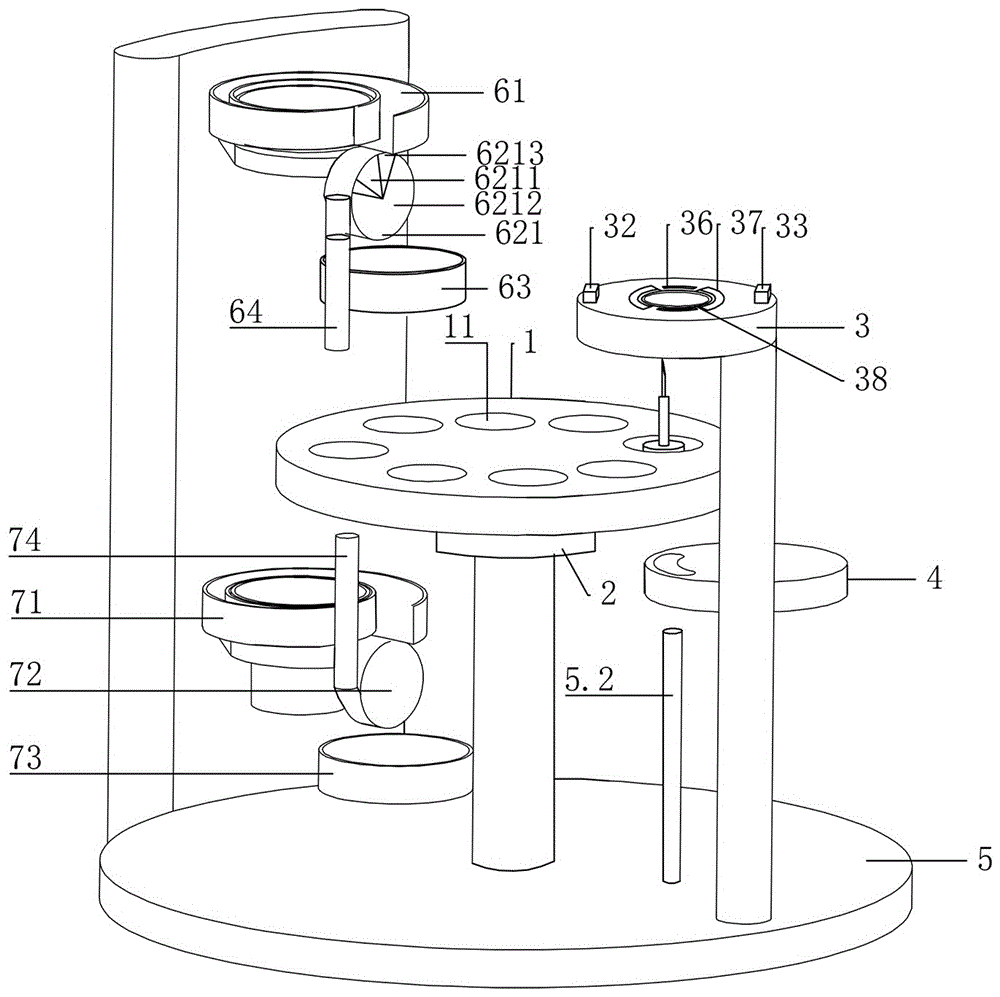

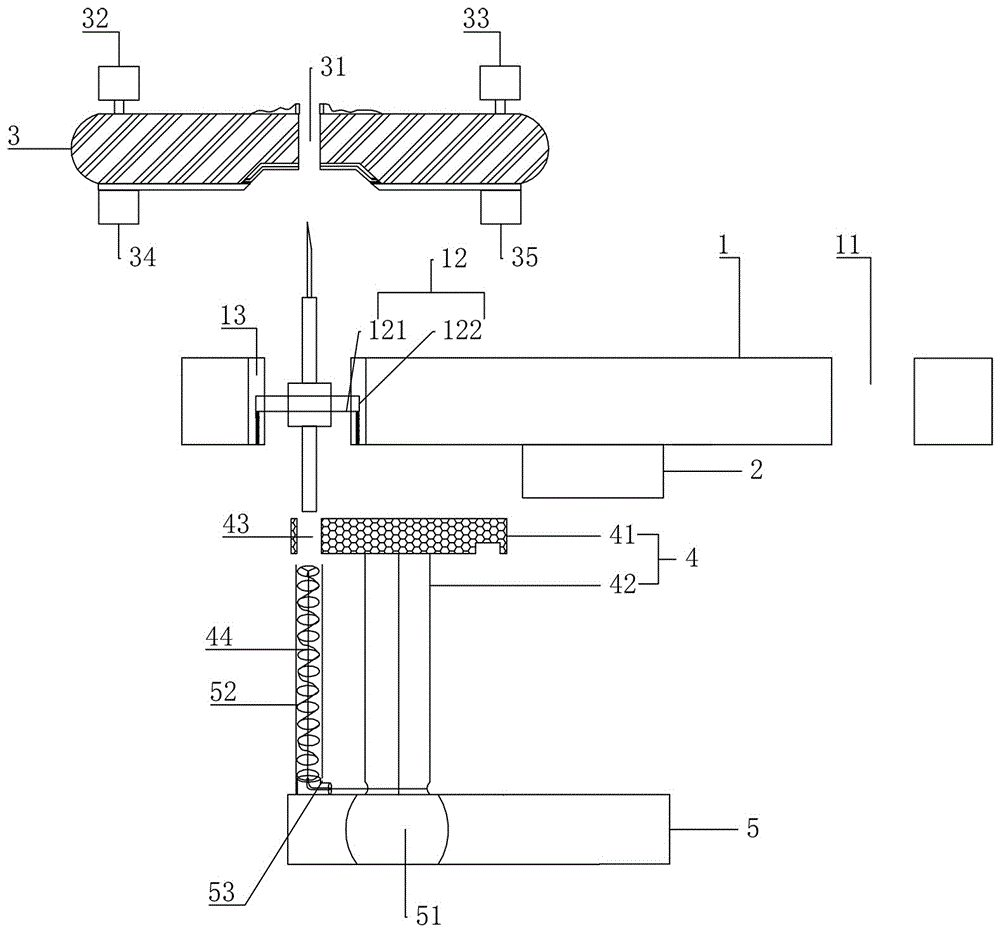

[0022] refer to Figure 1-8 As shown, the control system of a blood collection needle assembly machine in this embodiment includes a detection mechanism, an assembly mechanism, an indexing plate feeding mechanism, a manipulator mechanism and a host computer, and the assembly mechanism includes an outer casing feeding mechanism, an inner casing feeding mechanism, Front spring feeding mechanism, rear spring feeding mechanism, rear cover feeding mechanism and front cover feeding mechanism, indexing plate feeding mechanism, manipulator mechanism, outer casing feeding mechanism, inner casing feeding mechanism, front spring feeding mechanism, The rear spring feeding mechanism, the rear cover feeding mechanism and the front cover feeding mechanism are respectively provided with PLC controllers. The PLC controllers are respectively connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com