Nano composite material and preparation method thereof, and mercury ion detection method

A nano-composite material and magnetic separation technology, applied in the field of nano-materials, can solve the problems of packing column enrichment flow rate limitation, complicated operation, etc., and achieve the effects of accurate detection, simple operation and rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

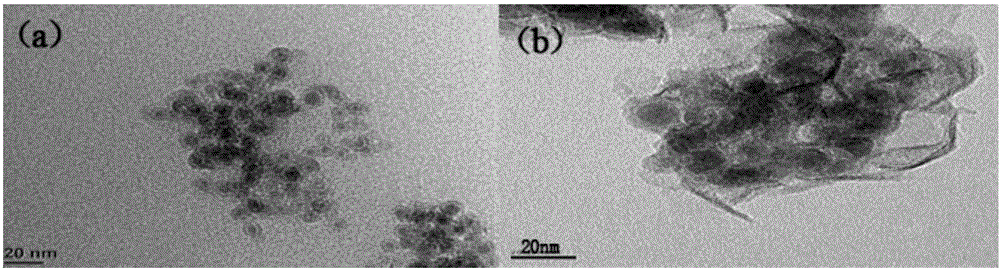

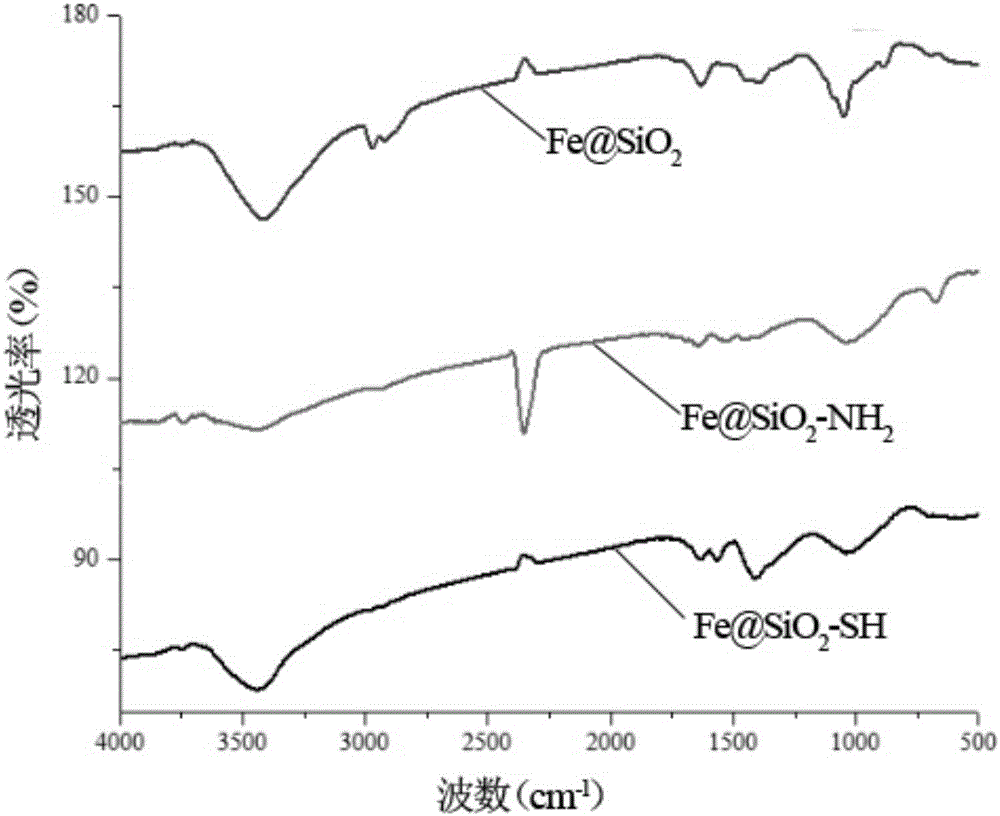

[0054] This embodiment provides a nanocomposite Fe@SiO 2 -SH, which is prepared by the following method:

[0055] Step 1, respectively weigh 0.87g of ferric chloride and 50mg of polyvinylpyrrolidone (PVP) and dissolve them in 60mL of ethanol solution with a volume fraction of 70%, add 0.2mL of tetraethyl orthosilicate (TEOS), and ultrasonically disperse for 20min Obtain solution A; Add 20mL concentration of 1mol / L sodium borohydride (NaBH 4 ) solution was reacted for 2 hours, and the experimental temperature was kept at 15°C during the reaction, followed by magnetic separation (in this embodiment, an external magnet was used to carry out magnetic separation of the reaction product), and then deionized water and absolute ethanol were used to wash 5 times successively, and the magnetic separation The non-magnetic by-products were removed, and finally vacuum-dried at 45 °C for 8 h to obtain Fe@SiO 2 .

[0056] Step 2, take the Fe@SiO obtained in step 1 2 Dissolve 0.4g in 40mL...

Embodiment 2

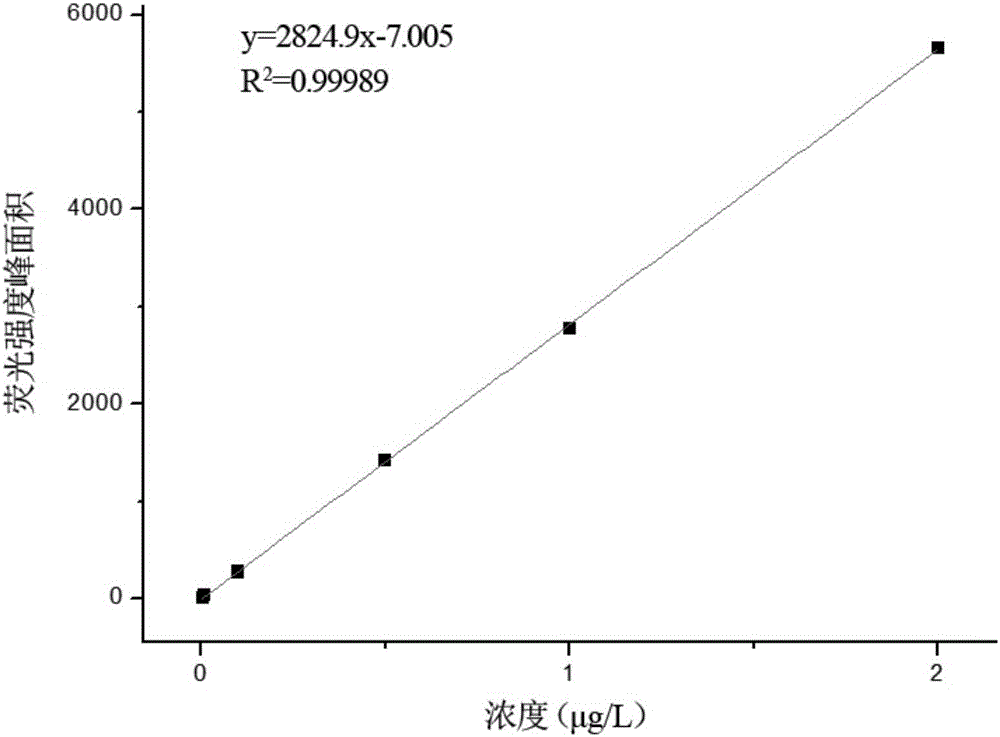

[0070] This example provides the Fe@SiO prepared in the example 2 -SH method for detecting mercury ions:

[0071] Step 1, take the nanocomposite material Fe@SiO prepared in the example 2 -SH ultrasonically disperses into the solution to be tested, adjust the pH value of the solution to be tested with hydrochloric acid and sodium hydroxide, and oscillate at a constant temperature at a temperature of 25°C with an oscillation speed of 270rpm for adsorption; then magnetically separate the adsorbed solution, Remove the solution and collect the adsorbed nanocomposites;

[0072] Step 2, adding hydrochloric acid solution to elute the adsorbed nanocomposite material with constant temperature oscillation, the oscillation temperature is 25°C, and the oscillation speed is 270rpm; then perform magnetic separation, take the supernatant and add hydrochloric acid to adjust to the amount added to the fluorescence carrier After coincidence, carry out fluorescence photometer detection, and cal...

Embodiment 3

[0085] Embodiment 3 Coexistence ion influence experiment

[0086] Weigh 8mg of the nanocomposite material Fe@SiO prepared in Example 1 2 -SH ultrasonic dispersion to 200mL mercury ion concentration is 0.0125ppb coexisting ions are Na + 、K + , Ca 2+ , Mg 2+ , Cl - The concentration is 100ppm, NO 3 - , SO 4 2- , CO 3 2- Concentration is 50ppm, Fe 3+ 、Cr 3+ , Mn 2+ Concentration of 100ppb, Cu 2+ , Pb 2+ 、Ni 2+ In different solutions with a concentration of 50ppb, 30ppb, and 30ppb, use hydrochloric acid and sodium hydroxide solution to adjust the pH to be neutral, add a film to seal, cover and tighten, and then place it in a water bath constant temperature oscillator with a temperature of 25°C and a speed of 270rpm Leave on for thirty minutes. After the shaking is completed, the reaction system is physically separated by an external magnetic field, and the solution part is discarded. After adding 2.5mL of 0.5% hydrochloric acid, place it in a water bath constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com