A special desulfurizer and deodorization process for the deodorization process of food waste

A technology for kitchen waste and desulfurizer, which is applied in other chemical processes, separation methods, combustion types, etc., can solve the problem of lack of deodorization means, and achieve low operation and maintenance costs, no secondary pollution, and strong removal performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

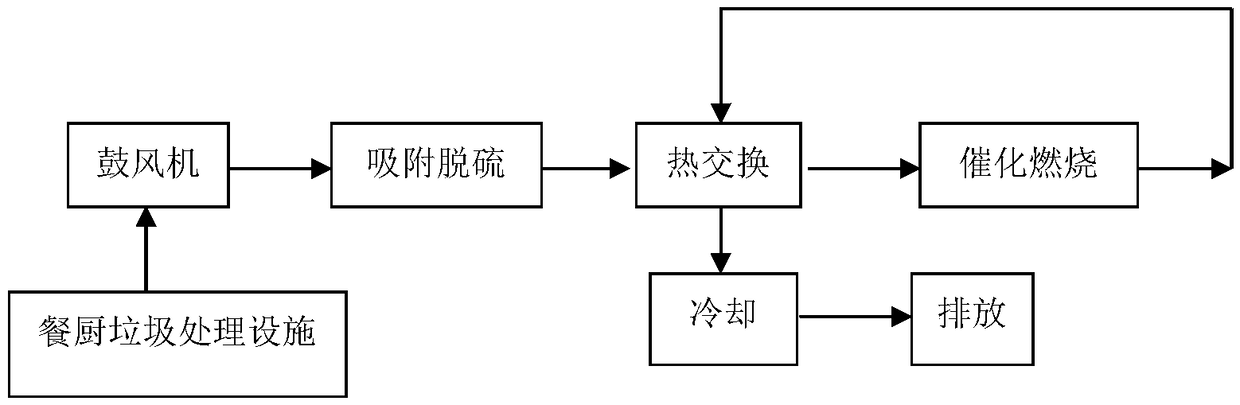

Method used

Image

Examples

Embodiment 1

[0038]The treated sludge of urban domestic sewage is placed in the mixing tank, and chemical conditioning agents ferric chloride and quicklime are added thereto. In terms of mass percentage, the addition of the chemical conditioning agent accounts for 10% of the sludge amount, and the amount of quicklime is The amount added accounts for 30% of the chemical conditioner, and after stirring, it is sent to filter plate for dehydration, the water content in the sludge is reduced to 40% after dehydration, and it is moved to the kneading tank, and nitric acid accounting for 5% by mass is added to it Copper or copper chloride or basic copper carbonate (dry basis, calculated as oxides) is extruded by kneading method, dried at 80°C for 4 hours and roasted at 400°C for 3 hours under the protection of inert gas to make a special desulfurizer.

[0039] A gas collection hood is installed above the waste treatment facilities, and the odorous gas is sent to the adsorption desulfurization devic...

Embodiment 2

[0044] Put the river sludge in the mixing tank, add chemical conditioner polyferric sulfate and quicklime therein, in terms of mass percentage, the addition amount of the chemical conditioner accounts for 1% of the sludge amount, and the addition amount of the quicklime accounts for 1% of the chemical conditioner 50%, after being stirred, it is sent to filter plate for dehydration by pressure filtration. After dehydration, the water content in the sludge is reduced to 60%, and it is moved to a kneading tank, and 50% by mass percentage of ferric nitrate or ferric chloride or Ferric oxide (dry basis, calculated as oxides) is extruded by kneading method, dried at 120°C for 2 hours and roasted at 200°C for 5 hours under the protection of inert gas to make a special desulfurizer.

[0045] A gas collection hood is installed above the waste treatment facilities, and the odorous gas is sent to the adsorption desulfurization device equipped with the special desulfurizer prepared above t...

Embodiment 3

[0050] The pond sludge is placed in the mixing tank, and the chemical conditioning agent polyaluminum ferric chloride and quicklime are added thereto. In terms of mass percentage, the addition of the chemical conditioning agent accounts for 5% of the sludge amount, and the addition of the quicklime accounts for 5% of the amount of the chemical conditioning. 40% of the agent, after being stirred, it is sent to filter plate for dehydration by pressure filtration. After dehydration, the water content in the sludge is reduced to 50%. It is moved to the kneading tank, and 40% by mass of manganese carbonate or manganese nitrate or manganese nitrate is added thereto. Ferromanganese ore powder (dry basis, calculated as oxides) is extruded by kneading method, dried at 100°C for 3 hours and roasted at 300°C for 4 hours under the protection of inert gas to make a special desulfurizer.

[0051] A gas collection hood is installed above the waste treatment facilities, and the odorous gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com