Sulfur/titanium dioxide/pyrolytic carbon composite positive electrode material for aluminum ion battery, preparation method for sulfur/titanium dioxide/pyrolytic carbon composite positive electrode material, and aluminum ion battery

A composite positive electrode material and aluminum ion battery technology, applied in battery electrodes, non-aqueous electrolyte storage batteries, circuits, etc., can solve the problems of limited improvement in the initial discharge capacity, energy density and cycle performance of aluminum ion batteries, and achieve improved liquid absorption and protection liquid capacity, high compatibility, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

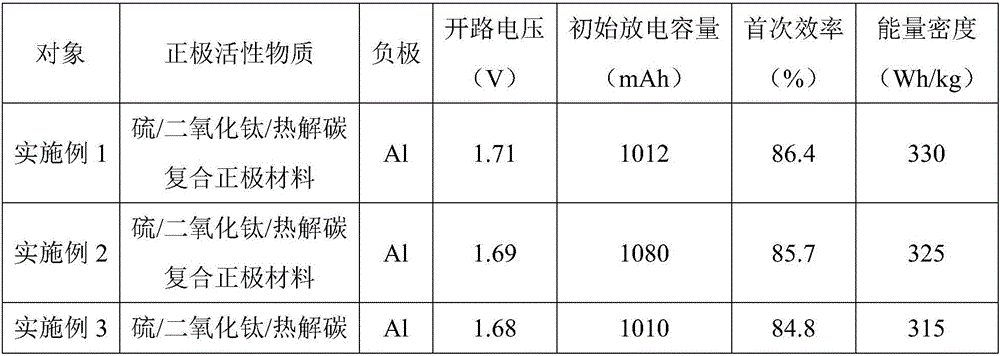

Embodiment 1

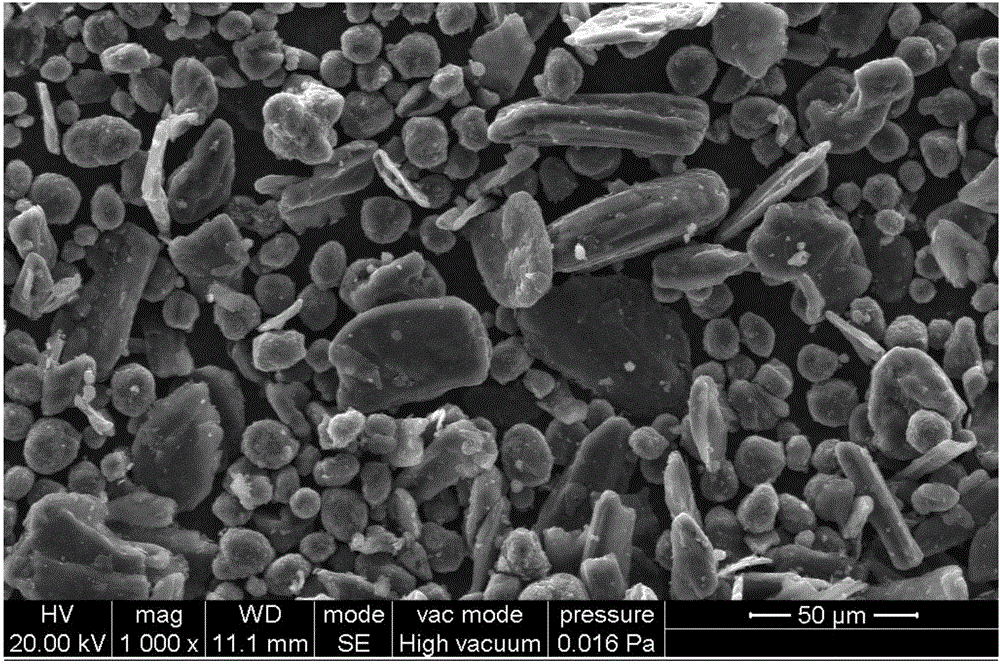

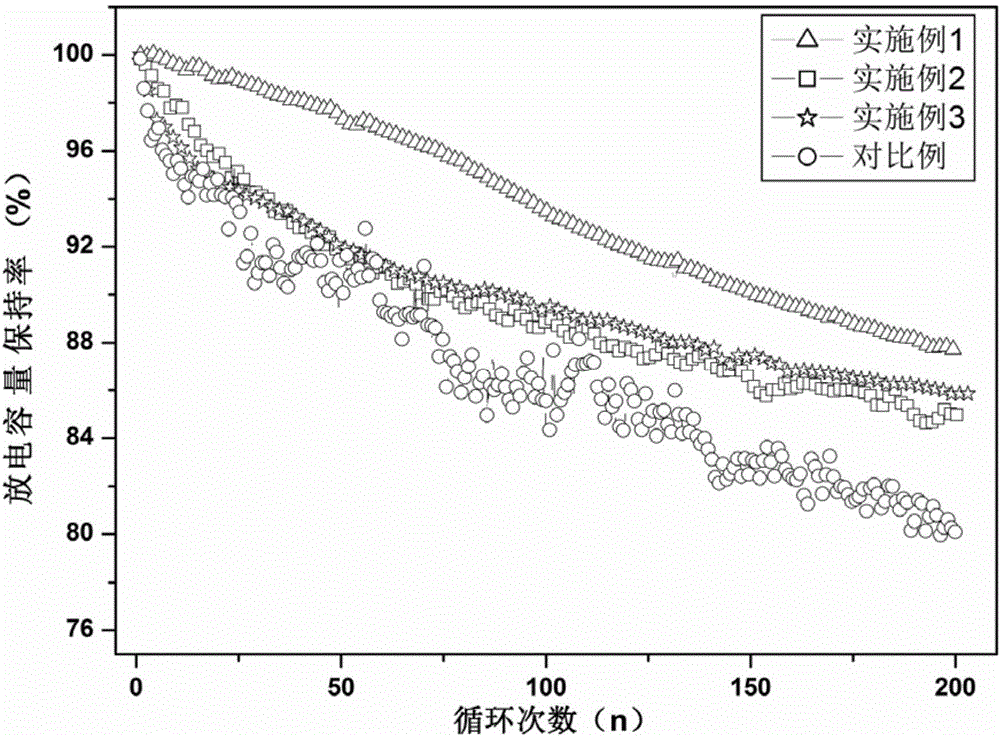

[0033] The sulfur / titanium dioxide / pyrolytic carbon composite positive electrode material for aluminum ion batteries of this embodiment has a core-shell structure, the core of the core-shell structure is elemental sulfur, and the shell is mainly composed of nano-titanium dioxide, carbon nanotubes, The coating layer formed by porous pitch pyrolysis carbon composite; wherein, the mass ratio of elemental sulfur to nano-titanium dioxide and carbon nanotubes is 1:3:0.5, and the mass ratio of nano-titanium dioxide to porous pitch forming pyrolytic carbon is 3:5 .

[0034] The preparation method of the aluminum ion battery sulfur / titanium dioxide / pyrolytic carbon composite positive electrode material of the present embodiment comprises the following steps:

[0035] 1) Preparation of porous asphalt:

[0036]Add 5g of asphalt into 150ml of anhydrous carbon tetrachloride, stir until the asphalt is completely dissolved to obtain a pitch-based carbon tetrachloride solution; place 10g of ...

Embodiment 2

[0046] The sulfur / titanium dioxide / pyrolytic carbon composite positive electrode material for aluminum ion batteries of this embodiment has a core-shell structure, the core of the core-shell structure is elemental sulfur, and the shell is mainly composed of nano-titanium dioxide, carbon nanotubes, A coating layer formed by composite porous pitch pyrolysis carbon; wherein, the mass ratio of elemental sulfur to nano-titanium dioxide and carbon nanotubes is 0.5:1:0.1, and the mass ratio of nano-titanium dioxide to porous pitch forming pyrolytic carbon is 1:1 .

[0047] The preparation method of the aluminum ion battery sulfur / titanium dioxide / pyrolytic carbon composite positive electrode material of the present embodiment comprises the following steps:

[0048] 1) Preparation of porous asphalt:

[0049] Add 1g of asphalt into 100ml of anhydrous carbon tetrachloride, stir until the asphalt is completely dissolved to obtain a pitch-based carbon tetrachloride solution; place 5g of ...

Embodiment 3

[0058] The sulfur / titanium dioxide / pyrolytic carbon composite positive electrode material for aluminum ion batteries of this embodiment has a core-shell structure, the core of the core-shell structure is elemental sulfur, and the shell is mainly composed of nano-titanium dioxide, carbon nanotubes, The coating layer formed by porous pitch pyrolysis carbon composite; wherein, the mass ratio of elemental sulfur to nano-titanium dioxide and carbon nanotubes is 5:5:1, and the mass ratio of nano-titanium dioxide to porous pitch forming pyrolytic carbon is 5:10 .

[0059] The preparation method of the aluminum ion battery sulfur / titanium dioxide / pyrolytic carbon composite positive electrode material of the present embodiment comprises the following steps:

[0060] 1) Preparation of porous asphalt:

[0061] Add 10g of asphalt into 200ml of anhydrous carbon tetrachloride, and stir until the asphalt is completely dissolved to obtain a pitch-based carbon tetrachloride solution; 50g of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com