Fully automatic liquid dispensing and injection device for polishing

A liquid injection device, polishing liquid technology, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increased labor intensity, poor reliability, short life, etc., to ensure personal safety, reduce contact Probability, the effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with embodiment now.

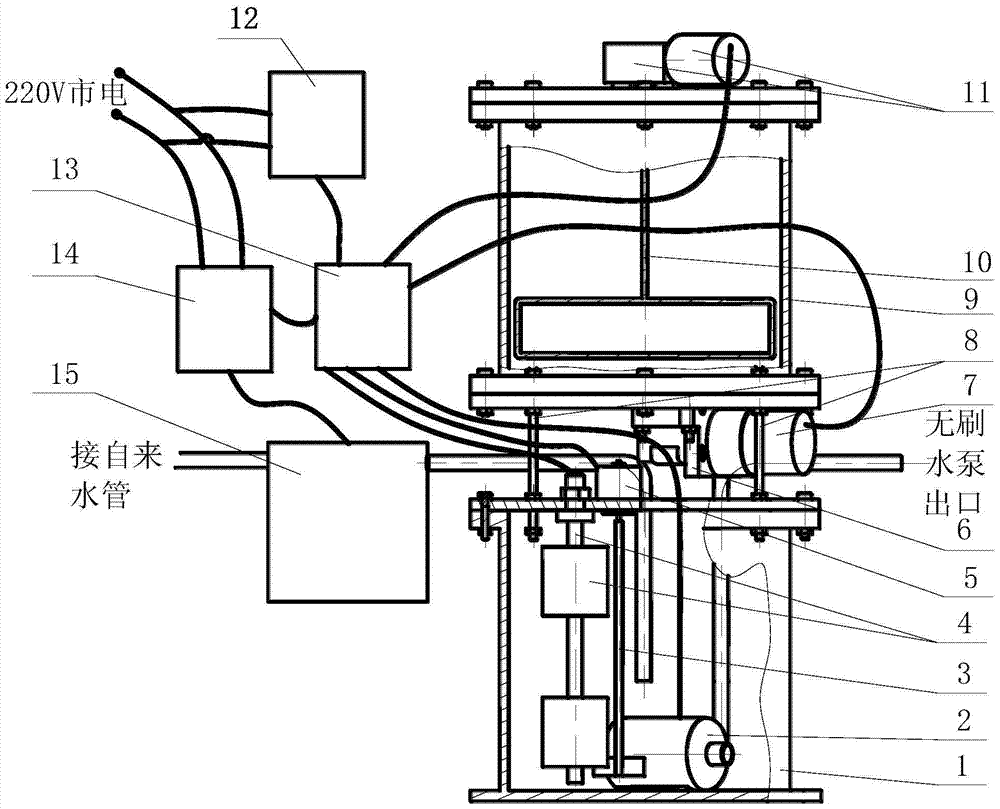

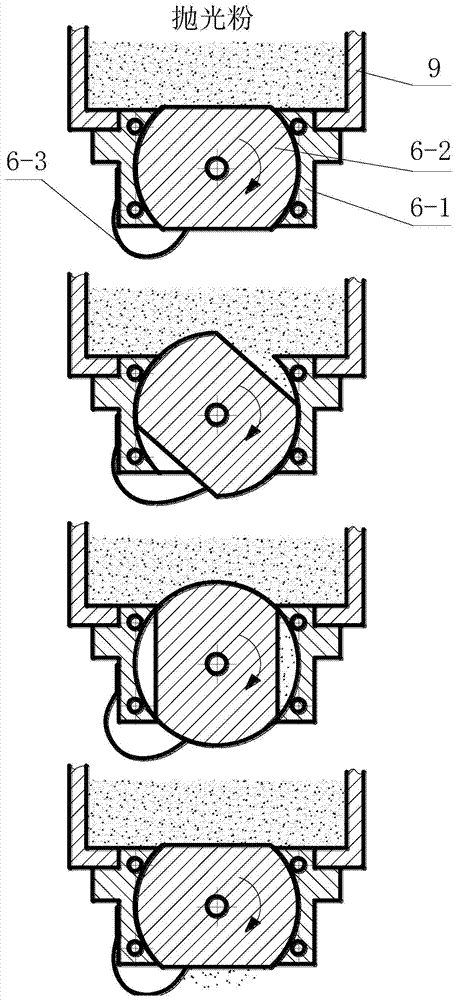

[0025] Please see figure 1 , figure 2 and image 3 , figure 1 It is a partial cross-sectional view of a fully automatic liquid preparation and injection device of the present invention, including a polishing liquid bottle 1, a brushless water pump 2, a polishing liquid stirring rotor 3, a liquid level sensor 4, a polishing liquid stirring motor 5, an automatic feeding device 6, Feed motor 7, connecting screw 8, storage bottle 9, polishing powder stirring rotor 10, polishing powder stirring motor 11, power supply 12, controller 13, AC contactor 14 and electromagnetic water valve 15, the positional relationship of the above components is as follows :

[0026] The bottom of the polishing liquid bottle 1 is provided with the brushless water pump 2, and the outlet pipe of the brushless water pump 2 leads to the outside of the bottle through the small hole on the bottle cap of the polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com