Epitaxial growth technology for nitride semiconductor luminescent device

A nitride semiconductor and epitaxial growth technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of low luminous efficiency, NH3 waste, and large consumption of long-wave nitride semiconductor light-emitting devices, so as to improve nitrogen partial pressure, Inhibit concentration and improve the effect of alloy quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

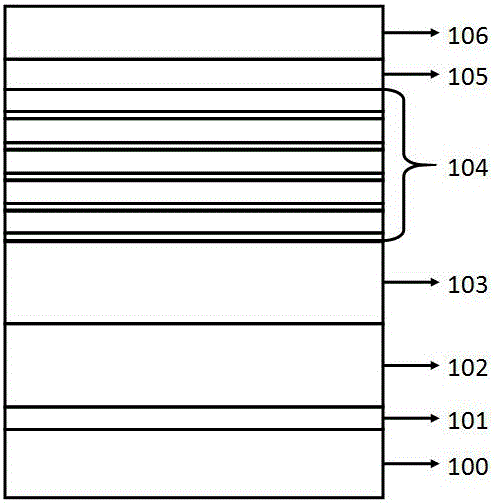

[0025] The In composition in the high In composition InGaN well layer is above 30%, and the growth temperature is between 600°C and 900°C. The nitrogen source required for growing a high In composition InGaN well layer is a nitrogen-containing compound with high decomposition ability below 700°C, and the V / III ratio of the nitrogen-containing compound to the group III source is 20-80:1.

Embodiment B

[0027] The In composition in the high In composition InGaN well layer is above 30%, and the growth temperature is between 600°C and 900°C. The nitrogen source required to grow a high In composition InGaN well layer is NH 3 A mixed gas composed of nitrogen-containing compounds with high decomposition ability below 700°C, the NH in the mixed gas 3 The mixing molar ratio of the nitrogen-containing compound with high decomposition ability below 700°C is 0-9:1, and the V / III ratio of the nitrogen source mixed gas to the Group III source is 20-1000:1.

[0028] Nitrogen-containing compounds that have a high decomposition ability below 700°C as described in Example A and Example B above may include the following compounds: monomethylhydrazine (CH 3 HNNH 2 , MMHy), dimethylhydrazine ((CH 3 ) 2 NNH 2 , DMHy), tert-butylhydrazine ((CH 3 ) 3 CHNNH 2 , TBHy), hydrazine (H2 NNH 2 ), etc., but not limited to this.

[0029] 5. An electron blocking layer 105 with a thickness of 15 nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com