A hydraulic clamping device for high-frequency fatigue test of thin-walled flat specimens

A fatigue test and hydraulic clamping technology, applied in the field of high-frequency fatigue test, can solve problems such as stress relaxation, and achieve the effect of solving stress relaxation, good controllability, ease of processing, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

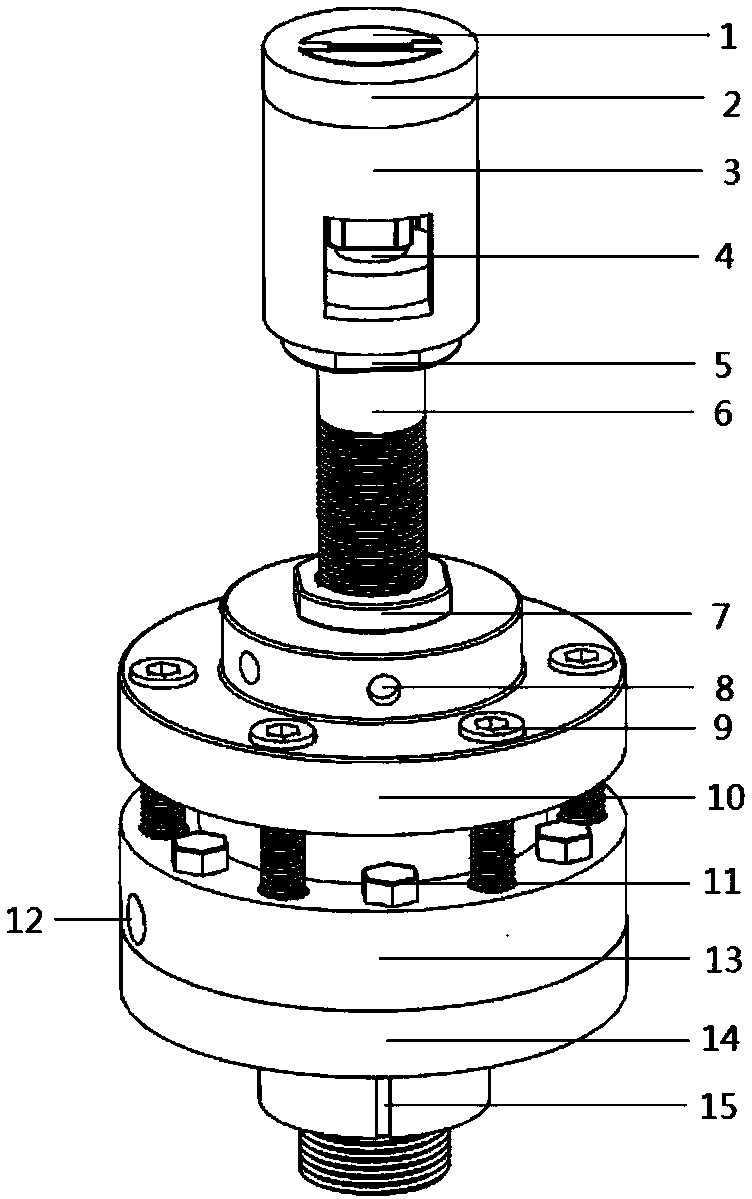

[0031] This embodiment is a hydraulic clamping device used for high frequency fatigue test of thin-walled flat test piece.

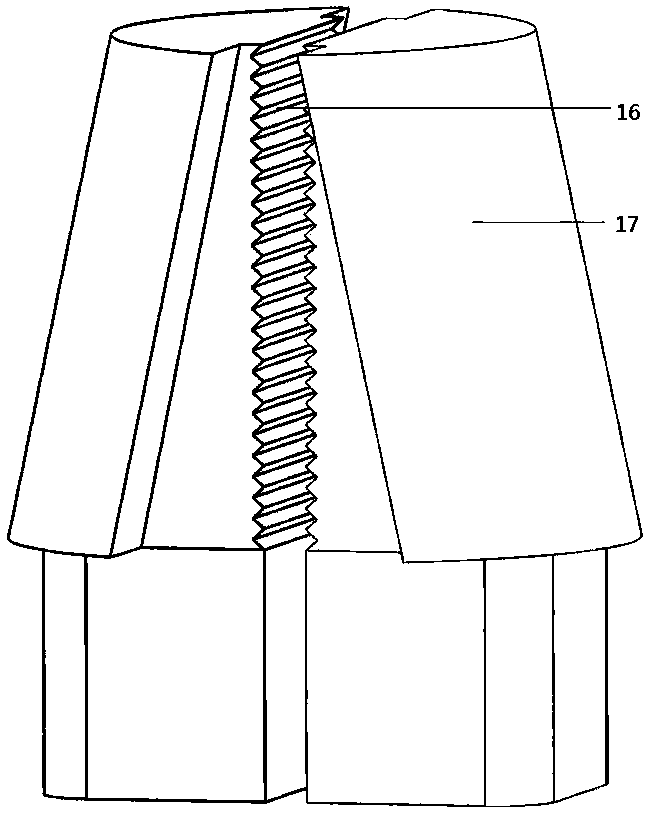

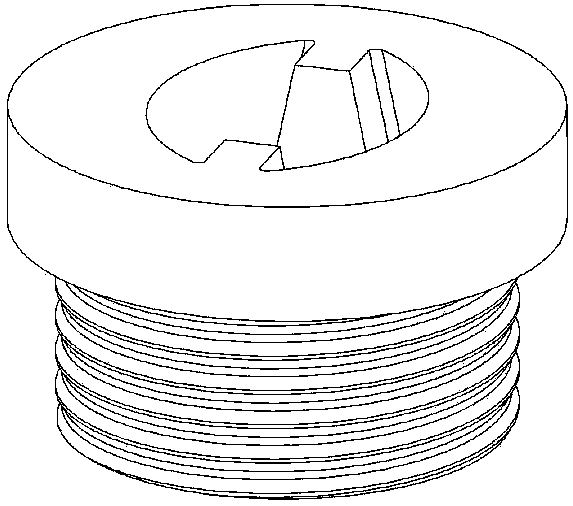

[0032] Refer to Figure 1 ~ Figure 12 This embodiment is used for the hydraulic clamping device for the high-frequency fatigue test of thin-walled flat specimens. It consists of a slider 1, a collet cover 2, a sleeve 3, a piston 4, an upper nut 5, a strut 6, a nut 7, and a cooling nozzle. 8. Bolt 9, water cooling plate 10, hexagonal bolt 11, hydraulic oil inlet 12, hydraulic cylinder 13, hydraulic chassis 14, lower nut 15, serrated teeth 16, slider arc 17, arc chute 18, rectangular hole 19 , Countersunk screw hole 20, spring 21, spring interface 22, hydraulic oil outlet 23; according to the strength requirements of the fatigue test, K403 is selected as the fixture material. Among them, the hydraulic cylinder 13 is disc-shaped, with multiple screw holes evenly distributed around the edge. The bottom of the middle cavity is processed with a hydraulic oil out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com