An automatic shrinkage grinder

A grinding machine and grinding mechanism technology, applied in the analysis of materials, cleaning methods using gas flow, sampling, etc., can solve the problems of increased cost, mutual pollution of materials, large occupation, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

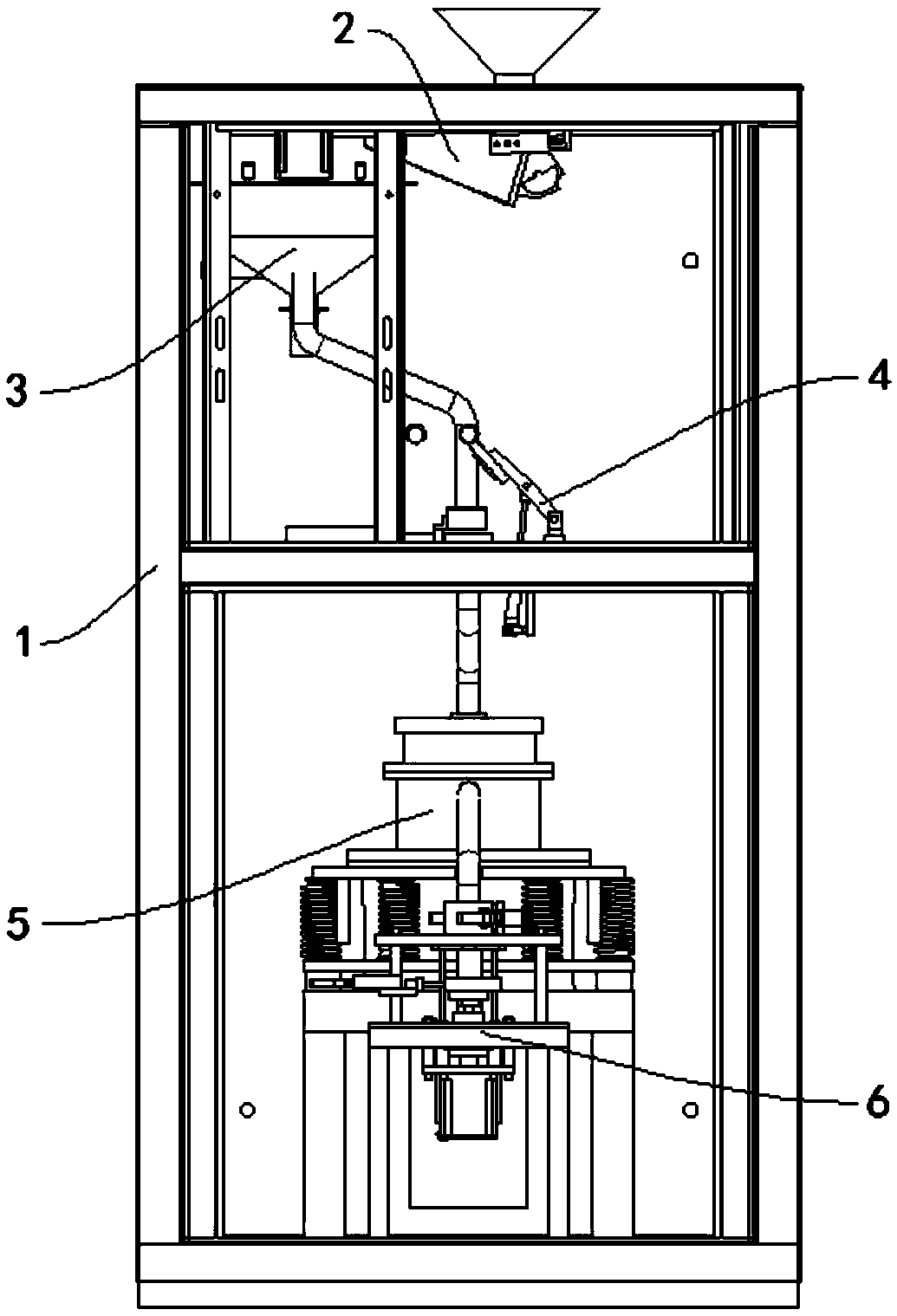

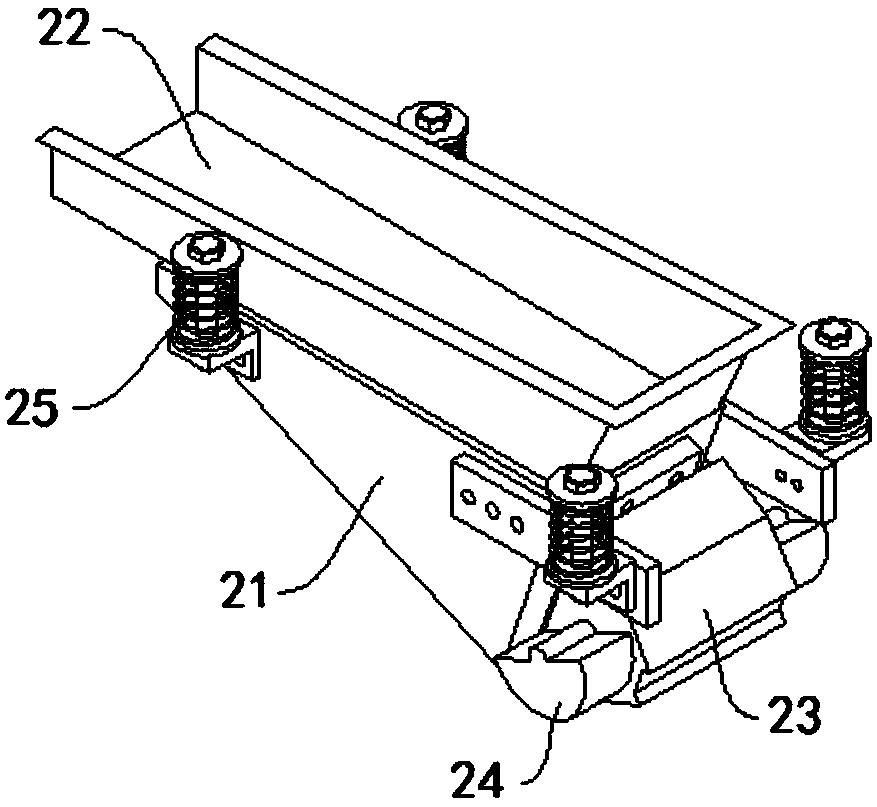

[0043] like figure 1 , figure 2 Shown, a kind of automatic shrinkage grinder, it comprises main frame 1 and the feeding mechanism 2 that is arranged on main frame 1, shrinkage mechanism 3, feeding mechanism 4, grinding mechanism 5, material receiving rotating mechanism 6, and The grinding mechanism 5 arranged on the ground, because the grinding mechanism 5 vibrates greatly, in order to ensure that the vibration will not affect other mechanisms, the grinding frame of the grinding mechanism 5 is placed on the ground alone, not connected with the main frame 1, and the grinding mechanism 5 It can be an existing technology, that is, a spring excitation system that drives an eccentric block by a motor, or an improved ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com