Flexible sensor and preparation method thereof

A flexible sensor and flexible insulating material technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement and other directions, can solve the problems of inaccessible, complicated, and difficult to flexible sensors, and achieves low cost, simple and convenient method, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The concrete steps of preparation are:

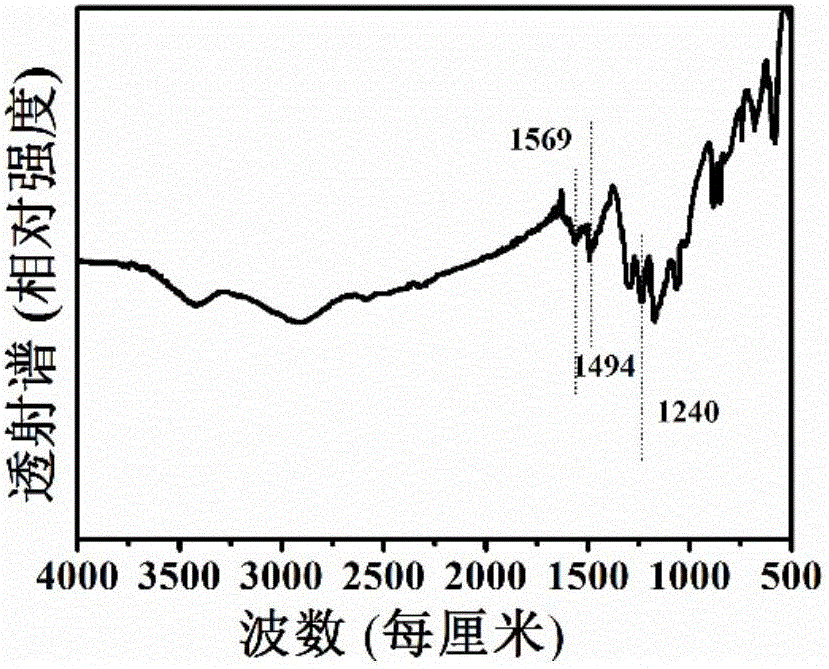

[0045] In step 1, the molar ratio of aniline and protonic acid is 0.8:2.2, and the two are mixed and then stirred evenly to obtain a transparent mixed solution; wherein, the protonic acid is sulfuric acid. Then put the positive electrode and graphite negative electrode in a transparent mixed solution, and the current density is 0.2A / cm 2 After 2 hours of electrodeposition, the following figure 1 Protonic acid-doped polyaniline coated on the positive electrode shown in the spectral line; wherein, the positive electrode is conductive glass.

[0046]Step 2, first bake the protonic acid-doped polyaniline covered on the positive electrode at 50°C for 30 minutes, and then install electrodes on the upper surfaces of both ends; where the electrodes are installed by using conductive silver glue to mix the wire with protonic acid The mixed polyaniline is connected to obtain the protonic acid-doped polyaniline covered on the positive elec...

Embodiment 2

[0048] The concrete steps of preparation are:

[0049] In step 1, the molar ratio of aniline and protonic acid is 0.9:2.1, and the two are mixed and then stirred evenly to obtain a transparent mixed solution; wherein, the protonic acid is sulfuric acid. Then put the positive electrode and graphite negative electrode in a transparent mixed solution, and the current density is 0.4A / cm 2 After 1.7h of electrodeposition, the following figure 1 Protonic acid-doped polyaniline coated on the positive electrode shown in the spectral line; wherein, the positive electrode is conductive glass.

[0050] Step 2, first bake the protonic acid-doped polyaniline covered on the positive electrode at 55°C for 25 minutes, and then install electrodes on the upper surfaces of both ends; wherein, the installation electrode is to use conductive silver glue to mix the wire with protonic acid The mixed polyaniline is connected to obtain the protonic acid-doped polyaniline covered on the positive elec...

Embodiment 3

[0052] The concrete steps of preparation are:

[0053] In step 1, the molar ratio of aniline and protonic acid is 1:2, the two are mixed and then stirred evenly to obtain a transparent mixed solution; wherein the protonic acid is sulfuric acid. Then put the positive electrode and graphite negative electrode in a transparent mixed solution, and the current density is 0.6A / cm 2 After 1.3h of electrodeposition, the following figure 1 Protonic acid-doped polyaniline coated on the positive electrode shown in the spectral line; wherein, the positive electrode is conductive glass.

[0054] Step 2, first bake the protonic acid-doped polyaniline covered on the positive electrode at 60°C for 20 minutes, and then install electrodes on the upper surfaces of both ends; wherein, the installation electrode is to use conductive silver glue to mix the wire with protonic acid The mixed polyaniline is connected to obtain the protonic acid-doped polyaniline covered on the positive electrode wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com