Rotary compressor and refrigeration cycle device having same

A technology of rotary compressor and compression mechanism, which is applied to rotary piston machinery, components of pumping devices for elastic fluids, and rotary piston/oscillating piston pump components, etc., which can solve the problem of oil drop in the compressor and other problems to achieve the effect of reducing oil discharge, sealing oil and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

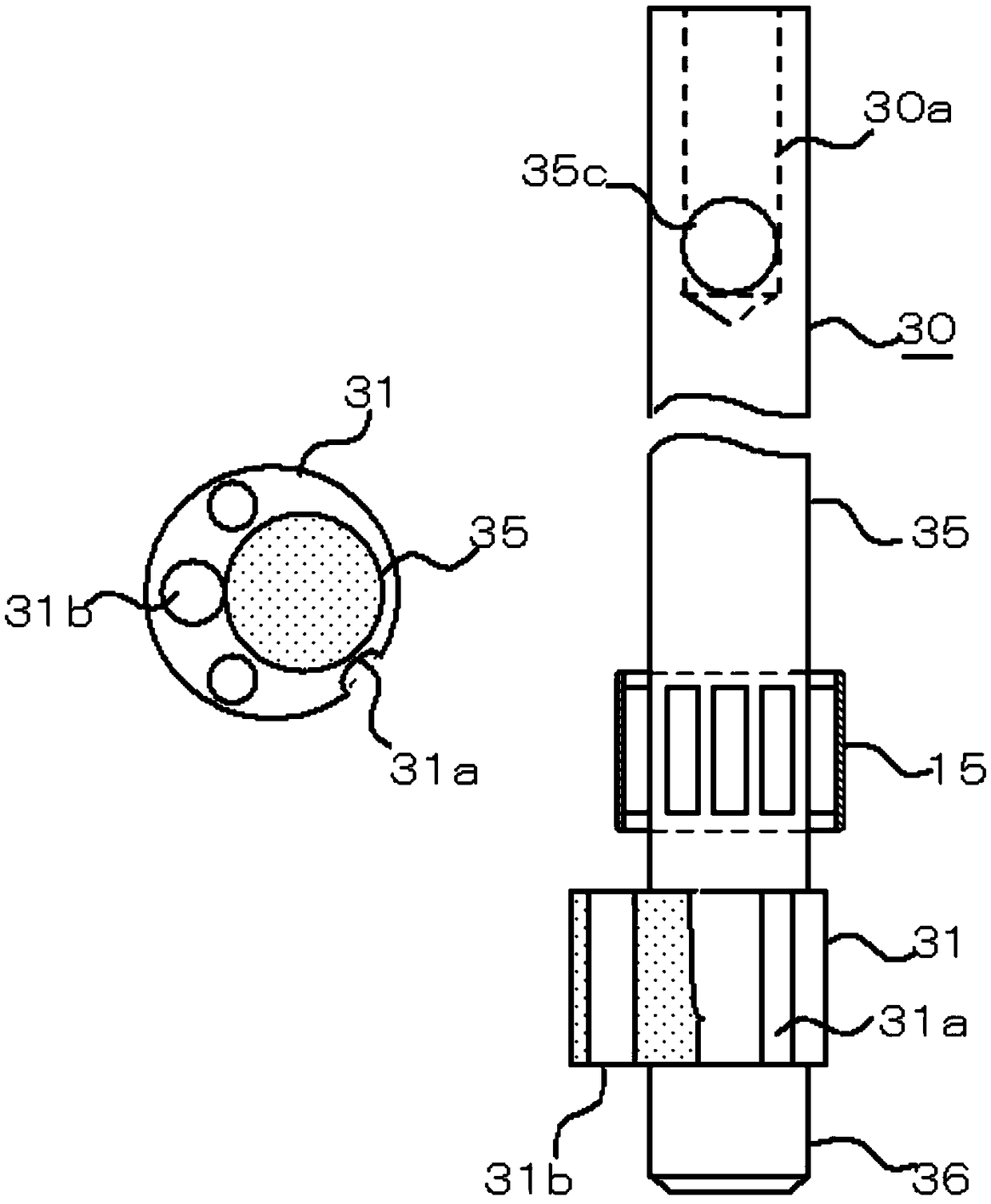

[0055] figure 1 It is an overall diagram of a single-cylinder rotary compressor and a diagram of a refrigeration cycle connected with the rotary compressor. figure 2 It is a detailed view of the compression mechanism part 5. figure 1 Among them, the outer peripheral wall of the stator 7 constituting the electric motor 4 (hereinafter referred to as the motor 4 ) and the outer peripheral wall of the second end plate 43 of the compression mechanism part 5 are fixed to the inner peripheral wall of the housing 2 .

[0056] The housing 2 is composed of a cylindrical housing, an upper housing end plate 2c and a lower housing end plate 2d welded at the upper and lower ends, and lubricating oil 9 (hereinafter referred to as oil 9 ) is injected into the oil storage tank 4 at the bottom of the housing 2 . The amount of sealed oil is much less than that of conventional rotary compressors.

[0057] The first compression chamber 11 a of the first cylinder 11 of the compression mechanism ...

Embodiment 2

[0087] Figure 5 It is an overall sectional view of a two-cylinder rotary compressor and a diagram of a refrigeration cycle connected to the rotary compressor. Figure 6 It is a detailed view of the compression mechanism unit 5 . Figure 5 Among them, the intermediate partition plate 50 is fixed on the inner peripheral wall of the housing 2 , and the first rolling bearing 15 is arranged in the intermediate partition plate 50 . The second rolling bearing 17 is disposed on the bearing bracket 18 fixed at the center of the bearing frame 19 .

[0088] The crankshaft 30 includes, in addition to a main shaft 35 and a counter shaft 36 , a first eccentric shaft 31 , a second eccentric shaft 32 , and an intermediate shaft 33 connected to these eccentric shafts. Therefore, the intermediate shaft 33 of the crankshaft 30 is in sliding engagement with the first rolling bearing 15 and the upper end of the main shaft 35 and the second rolling bearing 17 . At the center of the crankshaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com