A suction muffler applied to a compressor

A muffler and compressor technology, applied in the field of compressors, can solve the problems of reducing suction pulsation, failing to eliminate noise, and reducing the cooling capacity of the compressor, so as to reduce suction noise and suction pulsation, and ensure suction. Airtightness and the effect of reducing the amount of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Attached below Figure 1-15 The present invention is described in further detail with specific embodiment:

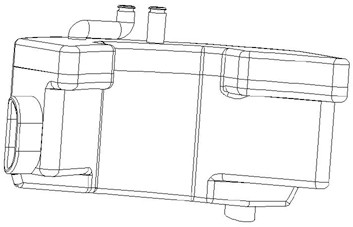

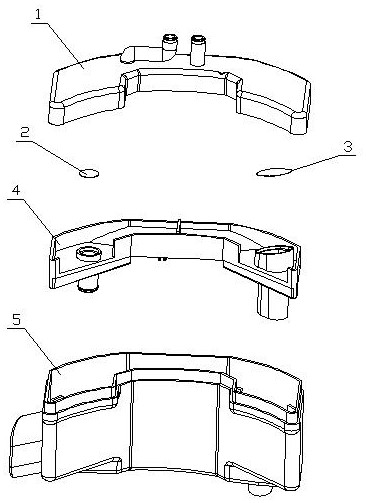

[0036] A suction muffler applied to a compressor, comprising an upper cover 1, a filter screen 1 2, a filter screen 2 3, a middle partition 4 and a casing 5;

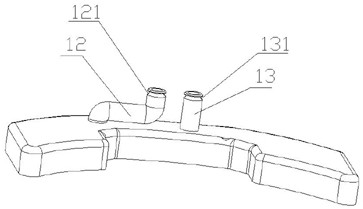

[0037] The top of the upper cover 1 is welded with an outlet pipe 1 12 and an outlet pipe 2 13, the bottom of the upper cover 1 is injection molded with an installation groove 14, and the middle of the upper cover 1 is injection molded with an installation groove 2 15;

[0038] The middle partition 4 includes a wall surface one 41 and a bottom surface one 40, the wall surface one 41 is injection molded on the periphery of the bottom surface one 40, and the bottom surface one 40 is integrally injection-molded by the slope one 43, the slope two 44 and the slope three 45, The middle part of the slope 44 is injection molded with a separation plate 42, and the two ends of the separation plate 42 are injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com