Water permeable type large-hole cement stabilized macadam pavement base layer material and preparation method thereof

A technology for stabilizing gravel and base material with cement, applied in the directions of roads, roads, pavement details, etc., can solve problems such as not involving drainage and storage, so as to improve social and economic benefits, reduce maintenance costs, and increase drainage and storage functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

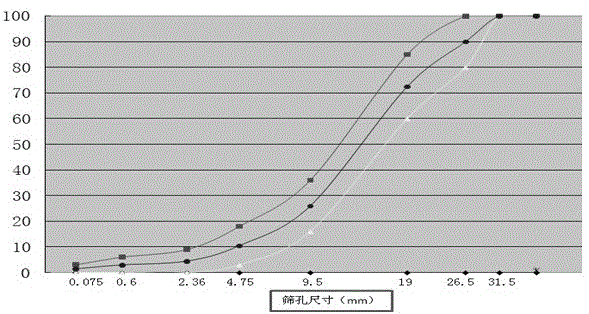

Image

Examples

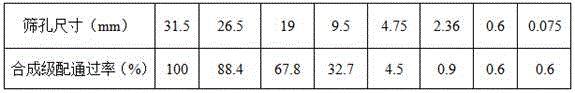

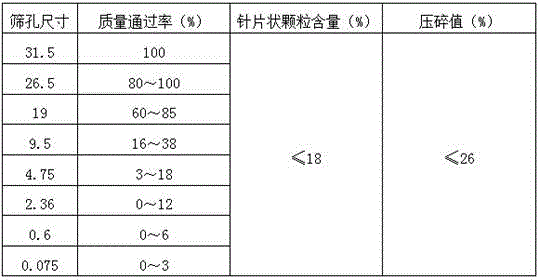

Embodiment 1

[0051] A permeable macroporous cement-stabilized macadam pavement material: See Table 2 for the mixture gradation, 10% cement dosage, 12.1% needle flake particle content, 18.4% crushing value, 0.38 water-cement ratio, no side The limit compressive strength test piece Ra=2.8MPa, the void ratio of the test piece is 19.5%, suitable for medium and light traffic.

Embodiment 2

[0053] A permeable macroporous cement-stabilized macadam pavement material mixture: see Table 2 for gradation, 10% cement dosage, 12.1% needle-like particle content, 18.4% crushing value, 0.43 water-cement ratio, no side The limited compressive strength test piece Ra=3.6MPa, the void ratio of the test piece is 18.8%, which is suitable for heavy traffic and medium and light traffic.

Embodiment 3

[0055] A permeable macroporous cement-stabilized macadam pavement material: see Table 2 for the mixture gradation, 10% cement dosage, 12.1% needle flake particle content, 18.4% crushing value, 0.48 water-cement ratio, no side The limit compressive strength test piece Ra=3.3MPa, the void ratio of the test piece is 19.1%, suitable for medium and light traffic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com