High-bulk coated white kraft paper and preparation method thereof

A technology of bulk and white coating, applied in the field of high-bulk coated white kraft paper and its preparation, can solve the problems of poor bursting resistance, slow ink absorption, low bulk, etc. Excellent effect of thickness stiffness and bursting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

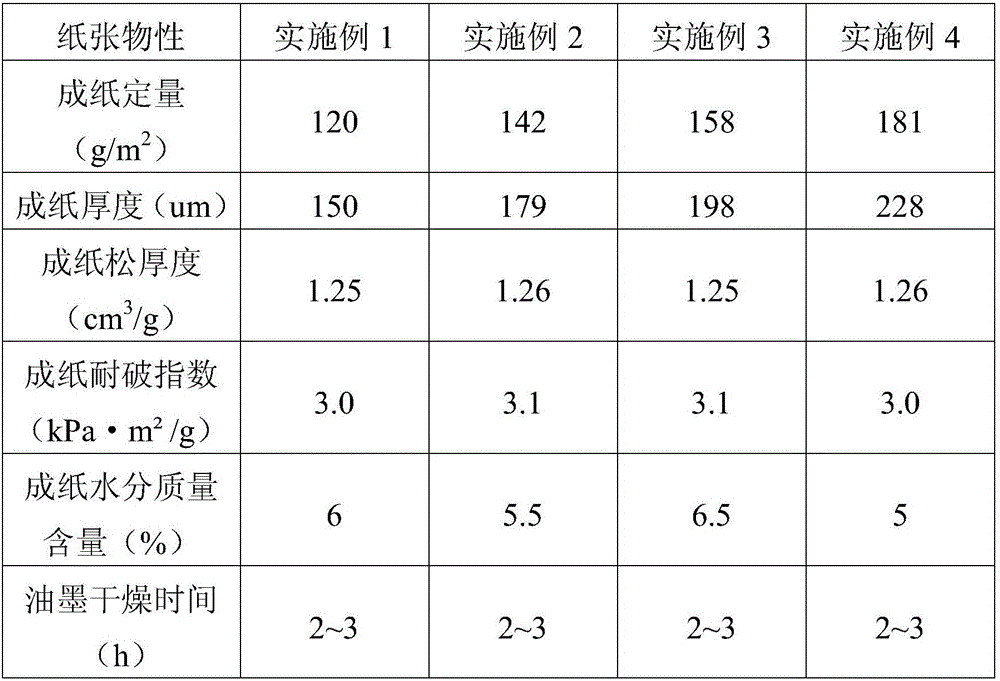

Examples

Embodiment 1

[0033] A kind of high-bulk coated white kraft paper, including base paper and coatings formed on both sides of the base paper, calculated by weight,

[0034] The pulp for making this base paper includes: 30 parts of kraft softwood pulp, the freeness after beating is 450ml, and the bulk is 1.25cm 3 / g; 52 parts of bleached kraft hardwood pulp, the freeness after beating is 420ml, and the bulk is 1.25cm 3 / g; 18 parts of bleached chemical thermomechanical pulp, the freeness after beating is 330ml, and the bulk is 2.8cm 3 / g; 8 parts of ground calcium carbonate, the average particle size of ground calcium carbonate particles is 1-2um; 0.8 parts of positive starch, the degree of substitution of positive starch is 0.025-0.03; and 1.2 parts of alkenyl succinic anhydride;

[0035] The paint for preparing the coating includes: 15 parts of superfine clay, the average particle size of ultrafine clay is 0.1-1um; 85 parts of ground calcium carbonate, the average particle size of ground c...

Embodiment 2

[0042] A kind of high-bulk coated white kraft paper, including base paper and coatings formed on both sides of the base paper, calculated by weight,

[0043] The pulp for making this base paper includes: 20 parts of kraft softwood pulp, the freeness after beating is 450ml, and the bulk is 1.3cm 3 / g; 65 parts of bleached kraft hardwood pulp, the freeness after beating is 420ml, and the bulk is 1.3cm 3 / g; 20 parts of bleached chemical thermomechanical pulp, the freeness after beating is 330ml, and the bulk is 3cm 3 / g; 8 parts of ground calcium carbonate, the average particle size of ground calcium carbonate particles is 1-2um; 0.8 parts of positive starch, the degree of substitution of positive starch is 0.025-0.03; and 1.2 parts of alkenyl succinic anhydride;

[0044] The paint for preparing the coating includes: 15 parts of superfine clay, the average particle size of ultrafine clay is 0.1-1um; 85 parts of ground calcium carbonate, the average particle size of ground calcium...

Embodiment 3

[0051] A kind of high-bulk coated white kraft paper, including base paper and coatings formed on both sides of the base paper, calculated by weight,

[0052] The pulp for making the base paper includes: 10 parts of kraft softwood pulp, the freeness after beating is 400ml, and the bulk is 1.25cm 3 / g; 70 parts of bleached kraft hardwood pulp, the freeness after beating is 380ml, and the bulk is 1.25cm 3 / g; 15 parts of bleached chemical thermomechanical pulp, the freeness after beating is 300ml, and the bulk is 2.8cm 3 / g; 5 parts of light calcium carbonate, the average particle size of which is 1-2um; 0.5 part of polyacrylamide and polyamide-polyamine-epichlorohydrin copolymer composition; and 0.8 part of ethylene maleic anhydride copolymer;

[0053] The paint for preparing the coating includes: 10 parts of superfine white clay, with an average particle size of 0.1-1um; 20 parts of china clay, with an average particle size of 1-2um; 70 parts of ground calcium carbonate, with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| free rate | aaaaa | aaaaa |

| free rate | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com