Environment-friendly leveling agent for disperse dye

A technology of disperse dyes and leveling agents, applied in dyeing, textile and papermaking, etc., can solve the problems of reducing foaming, high preparation cost, complex raw materials, etc., and achieve the effect of promoting adsorption, pure and full color, and increasing solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

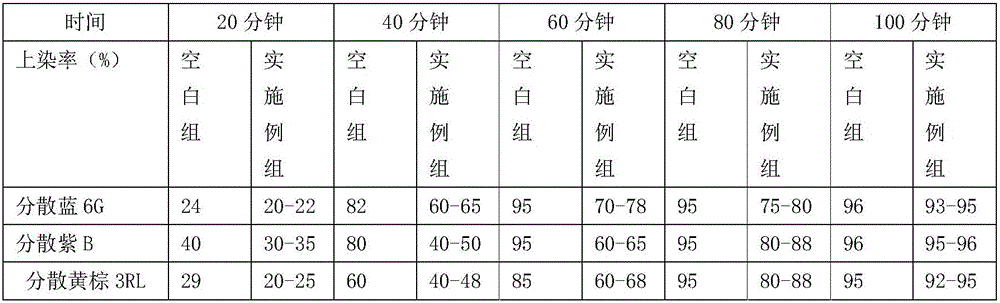

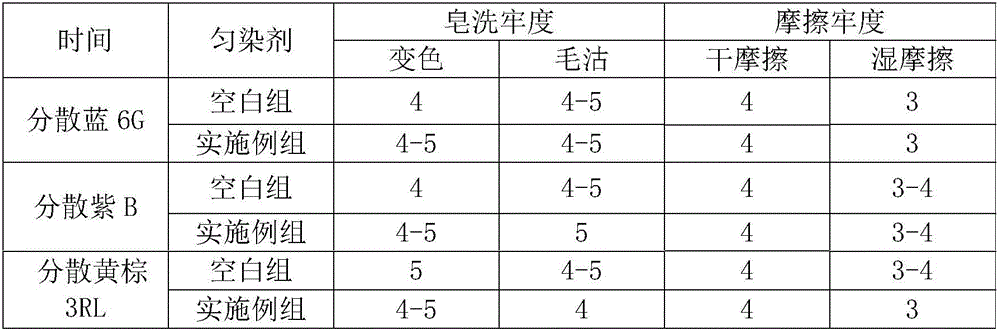

Examples

Embodiment 1

[0025] An environmentally friendly leveling agent for disperse dyes, consisting of the following components in parts by weight:

[0026] 0.01 part of dimethyl disulfide, 14 parts of sodium octadecyl toluene sulfonate, 5 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1 part of sodium thiosulfate, 15 parts of fatty alcohol polyoxyethylene ether, 90 parts of water.

[0027] The preparation method of the environment-friendly leveling agent for disperse dyes comprises the following steps:

[0028] Step 1: Mix and stir sodium octadecyl toluene sulfonate, 2-acrylamide-2-methylpropanesulfonic acid, fatty alcohol polyoxyethylene ether and water evenly, adjust the pH value to 6, and obtain the mixed material;

[0029] The second step: heat the mixed material obtained in the first step to 40°C, then slowly add dimethyl disulfide and sodium thiosulfate, and stir until uniform.

Embodiment 2

[0031] An environmentally friendly leveling agent for disperse dyes, consisting of the following components in parts by weight:

[0032] 0.02 parts of dimethyl disulfide, 17 parts of sodium octadecyl toluene sulfonate, 7 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1.4 parts of sodium thiosulfate, 20 parts of fatty alcohol polyoxyethylene ether, 120 parts of water.

[0033] The preparation method of the environment-friendly leveling agent for disperse dyes comprises the following steps:

[0034] Step 1: Mix and stir sodium octadecyl toluene sulfonate, 2-acrylamide-2-methylpropanesulfonic acid, fatty alcohol polyoxyethylene ether and water evenly, adjust the pH value to 7, and obtain the mixed material;

[0035] The second step: heat the mixed material obtained in the first step to 45°C, slowly add dimethyl disulfide and sodium thiosulfate, and stir until uniform.

Embodiment 3

[0037] An environmentally friendly leveling agent for disperse dyes, consisting of the following components in parts by weight:

[0038] 0.01 parts of dimethyl disulfide, 17 parts of sodium octadecyl toluene sulfonate, 5 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1.4 parts of sodium thiosulfate, 15 parts of fatty alcohol polyoxyethylene ether, 120 parts of water.

[0039] The preparation method of the environment-friendly leveling agent for disperse dyes comprises the following steps:

[0040] Step 1: Mix and stir sodium octadecyl toluene sulfonate, 2-acrylamide-2-methylpropanesulfonic acid, fatty alcohol polyoxyethylene ether and water evenly, adjust the pH value to 6, and obtain the mixed material;

[0041] The second step: heat the mixed material obtained in the first step to 45°C, slowly add dimethyl disulfide and sodium thiosulfate, and stir until uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com