Radix isatidis cellulose fiber and preparation method thereof

A technology of cellulose fiber and Radix isatidis, applied in the direction of single-component cellulose rayon, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of short slow-release period of active ingredients, bad effect, and weakened antibacterial effect. Achieve the effect of preventing and resisting viral cold, good antibacterial effect and improving immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 The preparation method of Radix isatidis cellulose fiber whose specification is 1.67dtex*38 mm

[0035] The preparation of step 1, Radix Radix Radix Microcapsules

[0036] (1) Selection of raw materials

[0037] Isatis root extract is selected as the raw material of Radix isatidis microcapsules, the extract of Radix isatidis is brownish-yellow powder, 100% passes through an 80-mesh sieve, the content of Radix isatidis is 60%, the ash content is ≤3.2%, the moisture content is ≤3.8%, and the heavy metal content is ≤5ppm, lead content≤1ppm, arsenic content≤0.5ppm, mercury content≤0.4ppm, total number of bacteria≤500cfu / g, total number of mold≤50cfu / g, Salmonella and Escherichia coli should not be detected.

[0038] (2) Preparation of wall material emulsion

[0039] Mix and dissolve maltodextrin, xanthan gum, and gum arabic into deionized water at 50°C, stir and emulsify at a stirring speed of 300r / min for 50min to prepare a wall material emulsion;

[0040] The...

Embodiment 2

[0071] Example 2 The experiment that the isatidis cellulose fiber prepared by the present invention improves immunity

[0072] Experimental method: choose 600 people, be divided into 2 groups, the present invention group and control group, main symptoms are: mental stress, irritability and insomnia, easy fatigue, easy cold, low immunity; the course of disease is between 6-8 weeks;

[0073] The group of the present invention: try on textiles made of 100% isatidis fibers prepared by the present invention for 3 months;

[0074] Control group: tried on textiles made of ordinary fibers for 3 months;

[0075] Efficacy evaluation criteria:

[0076] Cure: Energetic, quick thinking, symptoms of waist soreness and leg weakness disappear, God can sleep peacefully, immunity is improved, and appetite is strong;

[0077] Significantly effective: 3 of the above symptoms have improved;

[0078] Effective: Those who have improved 2 of the above symptoms;

[0079] Ineffective: none of the a...

Embodiment 3

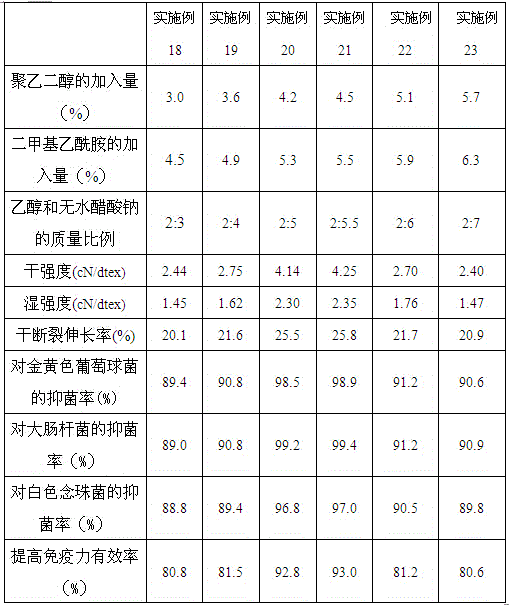

[0082] Example 3 Single Factor Analysis Experiment of Addition of Dispersant

[0083] Adopt the fiber preparation method described in embodiment 1, only change step 3, add dispersant step, the add-on of dispersant, carry out single factor analysis experiment, test the dry strength of the prepared fiber, wet strength, dry elongation at break, Bacteriostasis performance, adopt the method described in embodiment 2, test the effect that fiber improves immunity, see table 2 specifically.

[0084] Table 2 Single factor analysis experiment of dispersant addition amount

[0085]

[0086] From the above-mentioned single factor analysis experiment, it can be seen that embodiments 6 and 7 are preferred embodiments, that is, step 3, the step of adding dispersant, and the addition of dispersant is preferably 4-4.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com