Atmospheric supersonic-speed plasma spraying device capable of forming shielding gas hood

A technology of supersonic plasma and protective gas shield, which is applied in the direction of coating, molten spraying, metal material coating process, etc., which can solve the problems of large size and high spraying cost, and achieve the possibility of reducing oxidation, simple structure, and lower temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

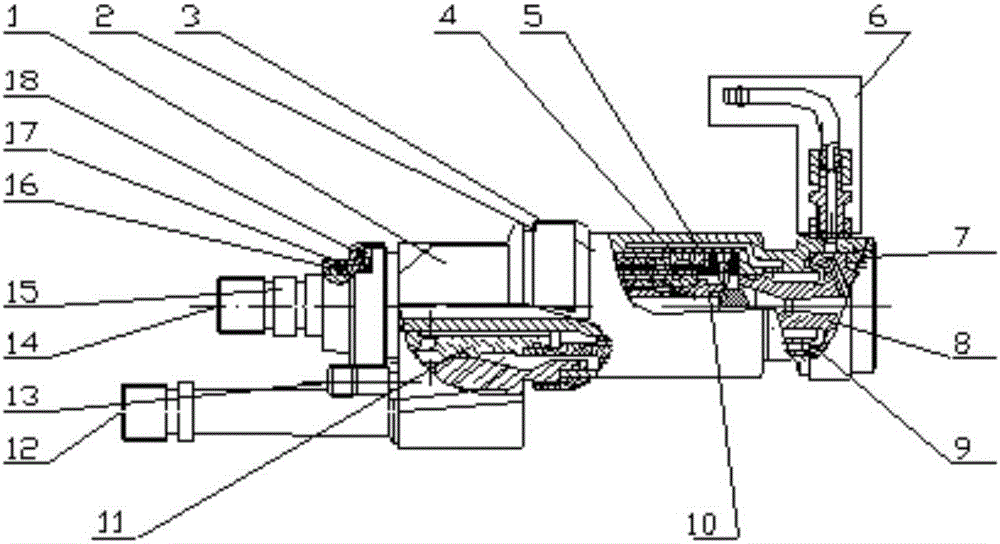

[0032] Such as figure 1 As shown, the present invention provides a kind of atmospheric supersonic plasma spraying device that forms protective gas cover, comprises gun seat 1, gun body pressure cap 2, gun body 3, insulator 4, gas swirl ring 5, powder feeding frame 6, Nozzle pressure cap 7, anode nozzle 8, diversion structure 9, cathode head 10, rear insulator 11, water inlet 12, plasma gas inlet 13, water outlet 14, cathode body 15, entire gasket 16, rear insulation pressure cap 17, Cathode body pressure cap 18 .

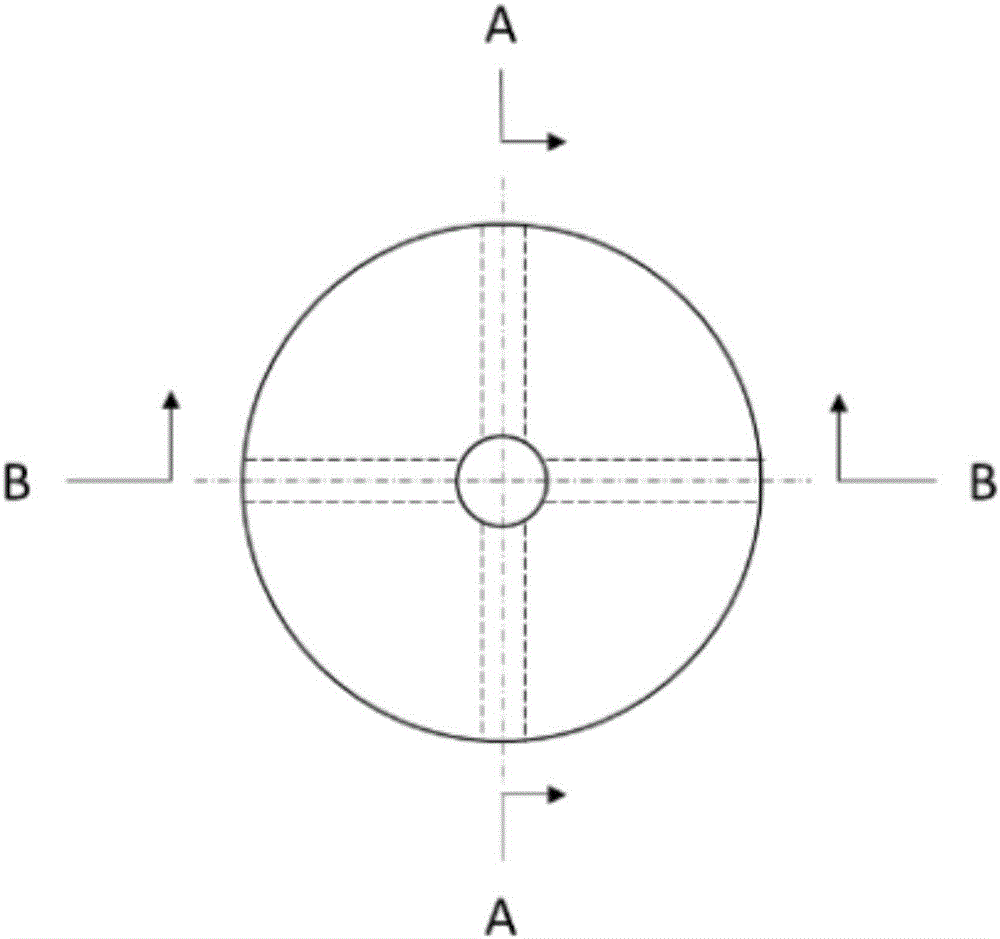

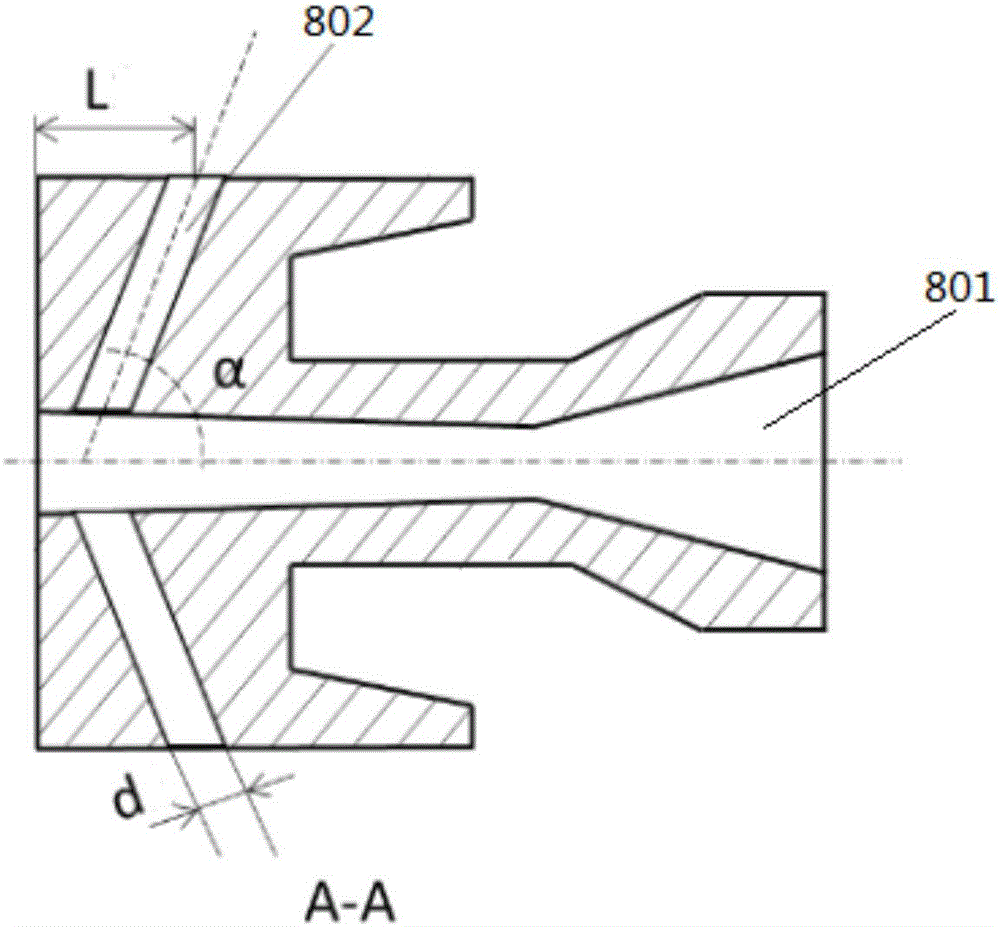

[0033] Such as figure 2 , image 3 , Figure 4 As shown, the anode nozzle 8 is in the shape of a body of revolution, and a central through hole 801 is provided at the central axis of the anode nozzle 8 , and a protective gas hole 802 and a powder feeding hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com