Rapid film-forming dust suppressant for high-intensity building construction site

A construction and dust suppressant technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as difficulty in raising dust and damage to film-type dust suppressants, and achieve improved dust suppression efficiency and good and fast film formation Sex and cohesiveness, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

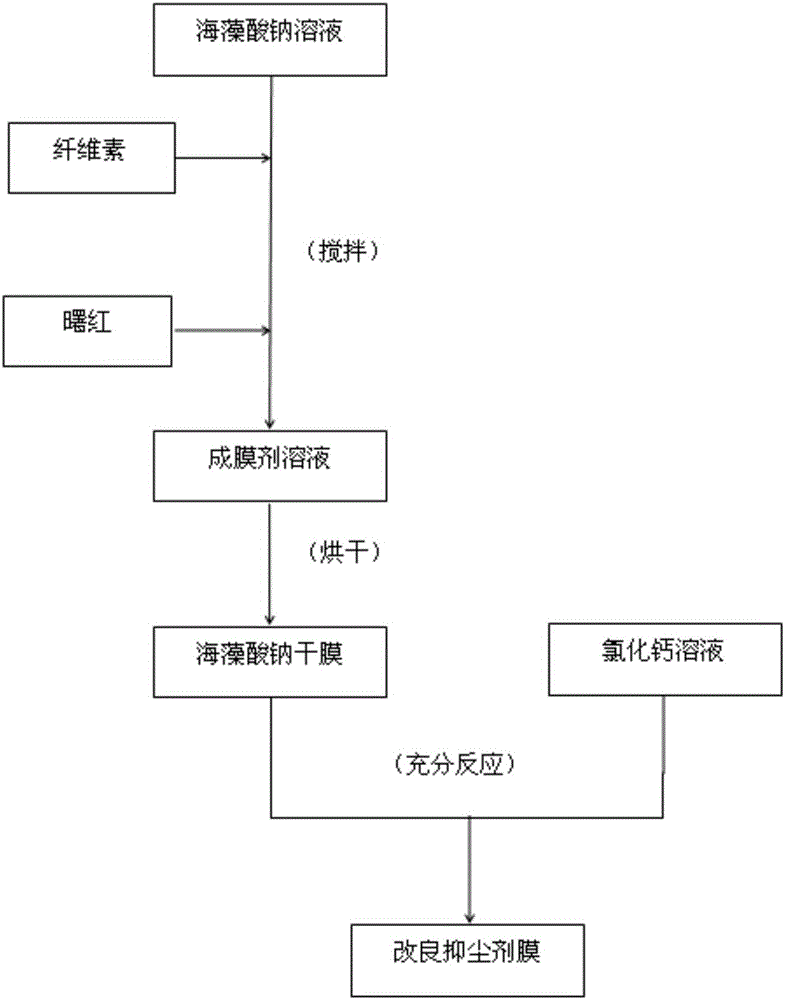

Method used

Image

Examples

Embodiment 1

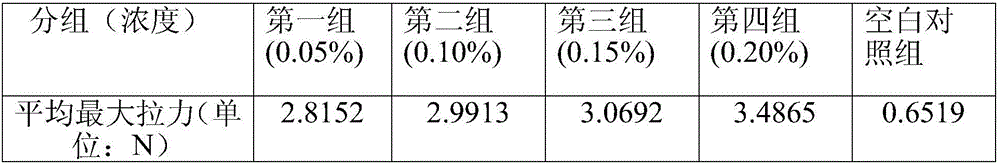

[0043] The composition of the high-strength building construction site rapid film-forming dust suppressant is:

[0044] Sodium alginate solution: the mass concentration of sodium alginate is 0.75%, and the mass concentration of methyl cellulose is 0.10%;

[0045] Calcium chloride solution: the mass concentration of calcium chloride is 7.5%.

[0046] How to use: After preparing sodium alginate solution (containing methyl cellulose) and calcium chloride solution, first spray the sodium alginate solution on the ground surface of the construction site, and then spray the above chlorine on the surface of the same construction site The spray ratio of calcium chloride solution, sodium alginate solution and calcium chloride solution is 1:0.80 by volume.

[0047] For areas where pedestrians and vehicles pass more frequently such as unhardened road surfaces and horse paths, after spraying the dust suppressant of the present invention, the consolidation layer and surface adhesive film a...

Embodiment 2

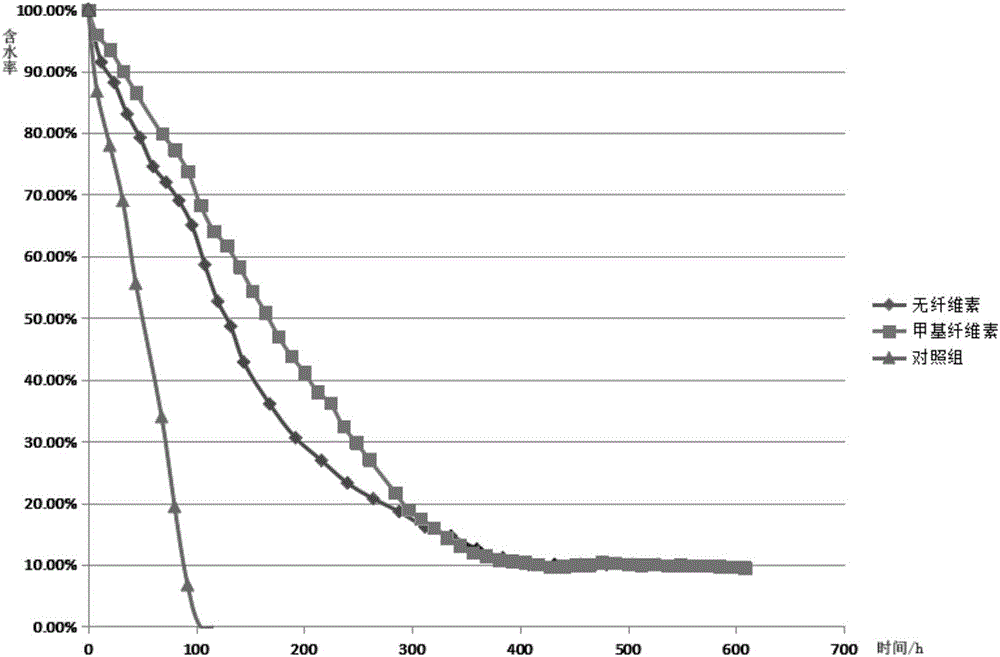

[0049] The mass concentration of methylcellulose in the sodium alginate solution is 0.05%, and the others are the same as in Example 1.

Embodiment 3

[0051] The mass concentration of methylcellulose in the sodium alginate solution is 0.15%, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com