Self-spraying self-adhesive type environment-friendly silica gel adhesive and preparation method thereof

A silicone glue, self-adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of the decline of the mechanical properties of the silica gel, the poisoning of the platinum catalyst, the poor compatibility of the silica gel, etc., and achieve easy operation. , good adhesion, good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

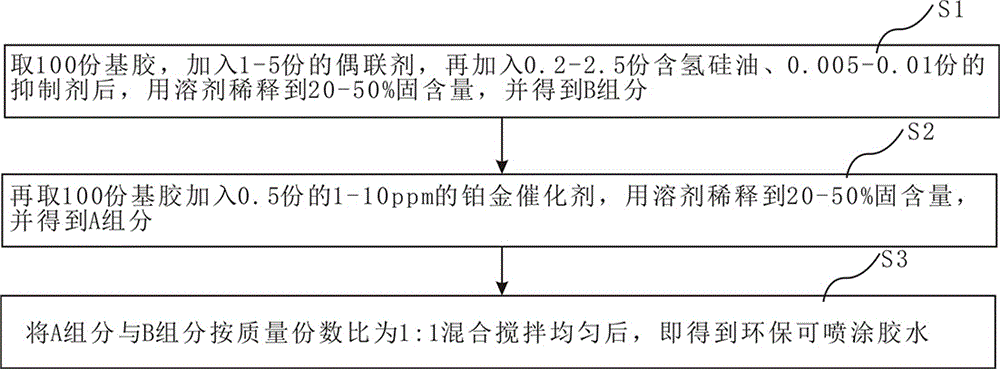

[0031] see figure 1 , the present invention also provides a preparation method of sprayable self-adhesive environmental protection silicone glue, comprising the following steps:

[0032] Step S1, take 100 parts of base glue, add 1-5 parts of coupling agent, then add 0.2-2.5 parts of hydrogen-containing silicone oil, 0.005-0.01 parts of inhibitor, dilute to 20-50% solid content with solvent, and Get component B;

[0033] Step S2, taking 100 parts of base glue and adding 0.5 parts of 1-10ppm platinum catalyst, diluting with solvent to 20-50% solid content, and obtaining A component;

[0034] In step S3, the component A and the component B are mixed and stirred evenly at a ratio of 1:1 by mass to obtain an environmentally friendly sprayable glue.

[0035] In this embodiment, the gum base includes the following components in terms of parts by mass: 40-60 parts of vinyl-terminated polydimethylsiloxane with a viscosity of 20,000-80,000, vinyl-terminated 20-40 parts of polydimethy...

Embodiment 1

[0043] Glue preparation and application

[0044] 50 parts of vinyl-terminated polydimethylsiloxane with a viscosity of 60,000, 18 parts of vinyl-terminated polydimethylsiloxane with a viscosity of 20,000, and 3 parts with a viscosity of 300 mPa.s vinyl mass fraction of 1% vinyl silicone oil, 26 parts of fumed silica, 5 parts of hexamethyldisilazane, 1.53 parts of water, add to kneader at room temperature and stir evenly, then heat up to 180°C, vacuum degree is 0.01MPa, After treatment for 3 hours, the base rubber was obtained after three-roll grinding.

[0045] Take 100 parts of base glue, add 5 parts of self-made coupling agent, then add 1.5 parts of hydrogen-containing silicone oil with hydrogen content of 0.85, 0.02 parts of inhibitor, dilute to 20% solid content with dimethylcyclosiloxane solvent, Obtain the B component.

[0046] Then take 100 parts of gum base, add 0.5 parts of 4000ppm platinum catalyst, and dilute to 20% solid content with dimethylcyclosiloxane solvent...

Embodiment 2

[0049] On the basis of Example 1, the solvent was diluted to a solid content of 30% with a mixed solvent of dimethyl carbonate and dimethylcyclosiloxane with a mass ratio of 1:1, and tested by the same method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com