A medical antibacterial needle-resistant rubber stopper and preparation method thereof

A rubber stopper, antibacterial and resistant technology, applied in the field of medical antibacterial needle-resistant rubber stopper and its preparation, can solve the problems of puncture debris, medical disputes, etc., and achieve good puncture ability, good product quality, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

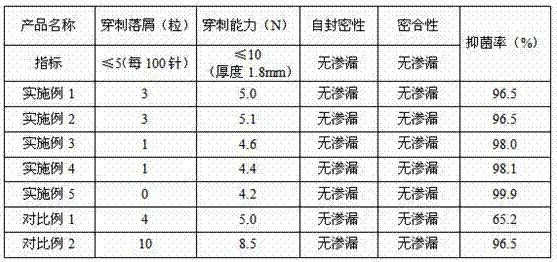

Examples

Embodiment 1

[0017] A medical antibacterial needle-resistant rubber stopper, which is prepared from the following ingredients in parts by weight: 120 parts of bromobutyl rubber, 1.5 parts of stearic acid, 5 parts of zinc oxide, 0.2 parts of sulfur, 6 parts of titanium dioxide, and 70 parts of calcined kaolin 0.1 part of accelerator ZDC, 0.5 part of accelerator DM, 0.8 part of 2-mercaptobenzimidazole, 20 parts of ethylene-ethyl acrylate copolymer, styrene-isoprene-styrene triblock copolymer 10 parts, 0.5 parts of galangal extract, 1.5 parts of calamus extract.

[0018] The preparation method of the above-mentioned medical antibacterial needle-resistant rubber stopper is as follows: (1) take galangal medicinal material and grind it, extract it with 80% ethanol under reflux, extract the extract with petroleum ether, chloroform, ethyl acetate respectively, after obtaining the active part, use silica gel The chemical components were separated and purified by column chromatography to obtain gala...

Embodiment 2

[0020] A medical antibacterial needle-resistant rubber stopper, which is prepared from the following ingredients in parts by weight: 90 parts of bromobutyl rubber, 0.5 parts of stearic acid, 2 parts of zinc oxide, 0.15 parts of sulfur, 10 parts of titanium dioxide, and 90 parts of calcined kaolin 1 part, 1 part of accelerator ZDC, 0.1 part of accelerator DM, 0.3 parts of 2-mercaptobenzimidazole, 10 parts of ethylene-ethyl acrylate copolymer, styrene-isoprene-styrene triblock copolymer 20 parts, galangal extract 1.5 parts, calamus extract 0.5 parts.

[0021] The preparation method of the above-mentioned medical antibacterial needle-resistant rubber stopper is as follows: (1) take galangal medicinal material and grind it, extract it with 80% ethanol under reflux, extract the extract with petroleum ether, chloroform, ethyl acetate respectively, after obtaining the active part, use silica gel The chemical components were separated and purified by column chromatography to obtain ga...

Embodiment 3

[0023] A medical antibacterial and needle-resistant rubber stopper, prepared from the following ingredients in parts by weight: 100 parts of bromobutyl rubber, 1.4 parts of stearic acid, 3 parts of zinc oxide, 0.18 parts of sulfur, 8 parts of titanium dioxide, and 80 parts of calcined kaolin 0.5 parts of accelerator ZDC, 0.4 parts of accelerator DM, 0.8 parts of 2-mercaptobenzimidazole, 15 parts of ethylene-ethyl acrylate copolymer, styrene-isoprene-styrene triblock copolymer 18 parts, galangal extract 1.4 parts, calamus extract 0.8 parts.

[0024] The preparation method of the above-mentioned medical antibacterial needle-resistant rubber stopper is as follows: (1) take galangal medicinal material and grind it, extract it with 80% ethanol under reflux, extract the extract with petroleum ether, chloroform, ethyl acetate respectively, after obtaining the active part, use silica gel The chemical components were separated and purified by column chromatography to obtain galangal ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com