Grinding aid for improving compatibility of cement and water reducing agent

A water-reducing agent and compatibility technology, applied in the field of cement grinding aids, can solve problems such as the adverse effect of cement strength, and achieve the effects of improving compatibility, ease of reconciliation, and slowing down hydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

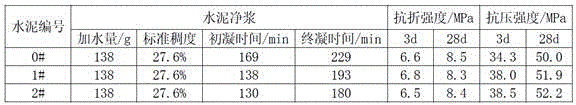

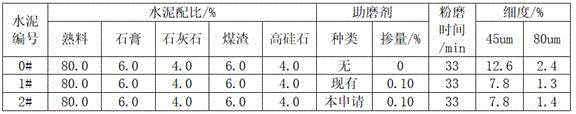

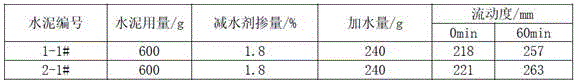

Examples

Embodiment 1

[0015] A grinding aid for improving the compatibility of cement and water reducer in this embodiment, including the following percentages by weight: 20% to 25% of diethanol monoisopropanolamine or triisopropanolamine, and 10% of inorganic salt ~15%, methylene succinic acid industrial waste liquid 20%~30%, and the balance is water. The processing method of this grinding aid is to sequentially mix water, diethanol monoisopropanolamine or triisopropanolamine, The inorganic salt is added to the methylene succinic acid industrial waste liquid, and stirred evenly. The grinding aid is suitable for ordinary Portland cement, fly ash cement and composite Portland cement, and the dosage is 0.10%.

[0016] The methylene succinic acid industrial waste liquid used in this example is the waste liquid produced by the fermentation method. The methylene succinic acid is also called itaconic acid, and the methylene succinic acid industry Waste liquid includes reducing sugar (about 23%-25%), ino...

Embodiment 2

[0034] A grinding aid for improving the compatibility of cement and water reducer in this embodiment includes the following percentages by weight: 20% triisopropanolamine, 15% inorganic salt, 25% methylene succinic acid industrial waste liquid %, the balance is water.

[0035] The processing method of this grinding aid is identical with embodiment 1.

Embodiment 3

[0037] A grinding aid for improving the compatibility of cement and water reducer in this embodiment, including the following percentages by weight: 24% diethanol monoisopropanolamine, 12% inorganic salt, methylene succinic acid industrial waste Liquid 20%, the balance is water.

[0038] The processing method of this grinding aid is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com