Air-generating agent for air-entrained concrete and its application method

A technology of air-entrained concrete and air-entraining agent, applied in the field of building materials, can solve problems such as restricting the development of air-entrained concrete, and achieve the effects of low price, simplified production process and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

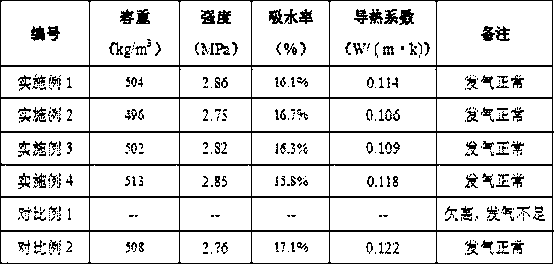

Examples

Embodiment 1

[0020] (1) Ferrosilicon powder, fineness 45um sieve is 2%, silicon content is 98%.

[0021] (2) Dissolve 4 grams of sodium hydroxide in water to prepare a 1.5% mass concentration sodium hydroxide solution, heat it to 60°C, add 1 gram of ferrosilicon powder, and stir for 1 min.

[0022] (3) According to the process flow of using aluminum powder air-generating agent to prepare air-entrained concrete, ferrosilicon powder is used as air-generating agent to prepare air-entrained concrete.

Embodiment 2

[0024] (1) Ferrosilicon powder, fineness 45um sieve is 4%, silicon content is 98%.

[0025] (2) Dissolve 6 grams of sodium hydroxide in water to make a sodium hydroxide solution with a mass concentration of 2.05%, heat it to 57°C, add 1 gram of ferrosilicon powder, and stir for 1.5 minutes.

[0026] (3) According to the process flow of using aluminum powder air-generating agent to prepare air-entrained concrete, ferrosilicon powder is used as air-generating agent to prepare air-entrained concrete.

Embodiment 3

[0028] (1) Ferrosilicon powder, fineness 45um sieve is 6%, silicon content is 98%.

[0029] (2) Dissolve 8 grams of sodium hydroxide in water to make a sodium hydroxide solution with a mass concentration of 2.55%, heat it to 55°C, add 1 gram of ferrosilicon powder, and stir for 2 minutes.

[0030] (3) According to the process flow of using aluminum powder air-generating agent to prepare air-entrained concrete, ferrosilicon powder is used as air-generating agent to prepare air-entrained concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com