The construction process of the protective pipe of the fpso seawater lift pump

A technology for seawater lifting pumps and protective pipes, which is applied in ship construction, floating buildings, ship components, etc. It can solve problems affecting the roundness and straightness of protective pipes, increase construction costs, maintenance costs, collisions, etc., and achieve precision control Requirement, reduction of repeated coating period, convenient installation and positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

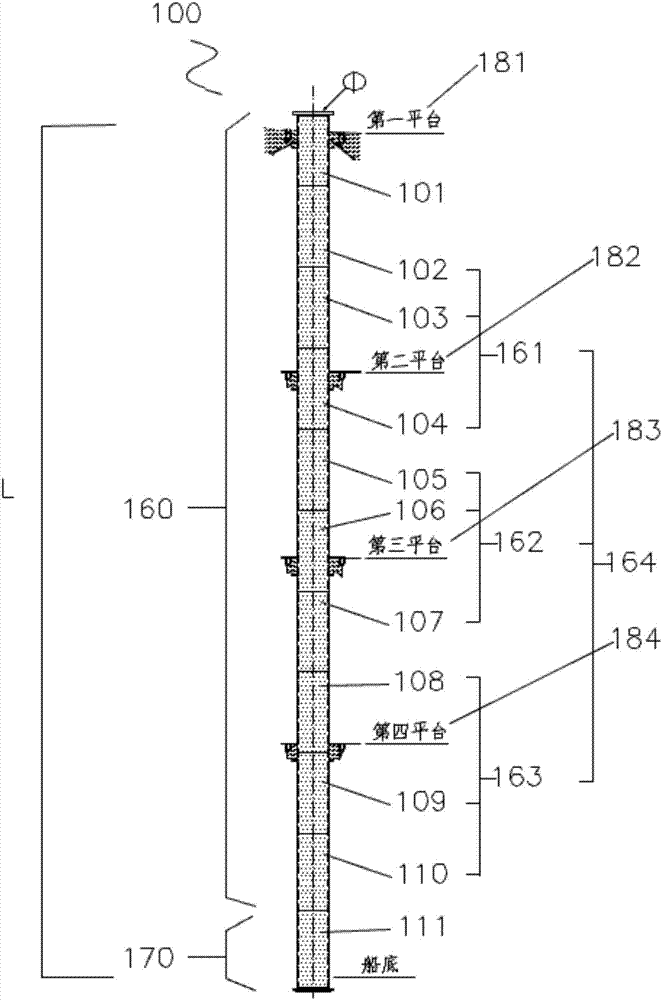

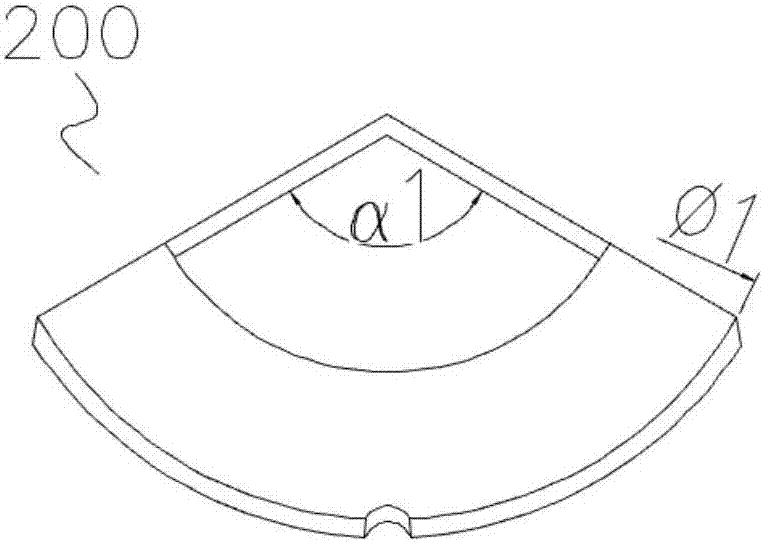

[0036] Please also see Figure 1 to Figure 7 , figure 1It is a structural schematic diagram of the protection pipe of the FPSO seawater lift pump of the present invention, figure 2 It is a structural schematic diagram of arc-shaped tooling in the present invention, image 3 It is a structural schematic diagram of the ring tooling in the present invention, Figure 4 It is a schematic diagram of the butt jointing process of the base section in the present invention, Figure 5 It is a schematic structural view of the outer arc code plate in the present invention, Figure 6 It is a schematic structural view of the inner arc code plate in the present invention, Figure 7 It is a schematic diagram of the welding process of the longitudinal welding zone in the present invention.

[0037] Construction and hoisting process of the protective pipe of the FPSO seawater lift pump of the present invention The protective pipe 100 of the seawater lift pump to be built is located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com