Self-sticking macromolecular pre-laid waterproof roll material and preparation method

A waterproof membrane and polymer technology, applied in chemical instruments and methods, layered products, building components, etc., can solve the problems of no treatment on the surface of the membrane, poor adhesion of post-cast concrete, and low cohesive strength , to achieve strong anti-ultraviolet ability, control water channeling phenomenon, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

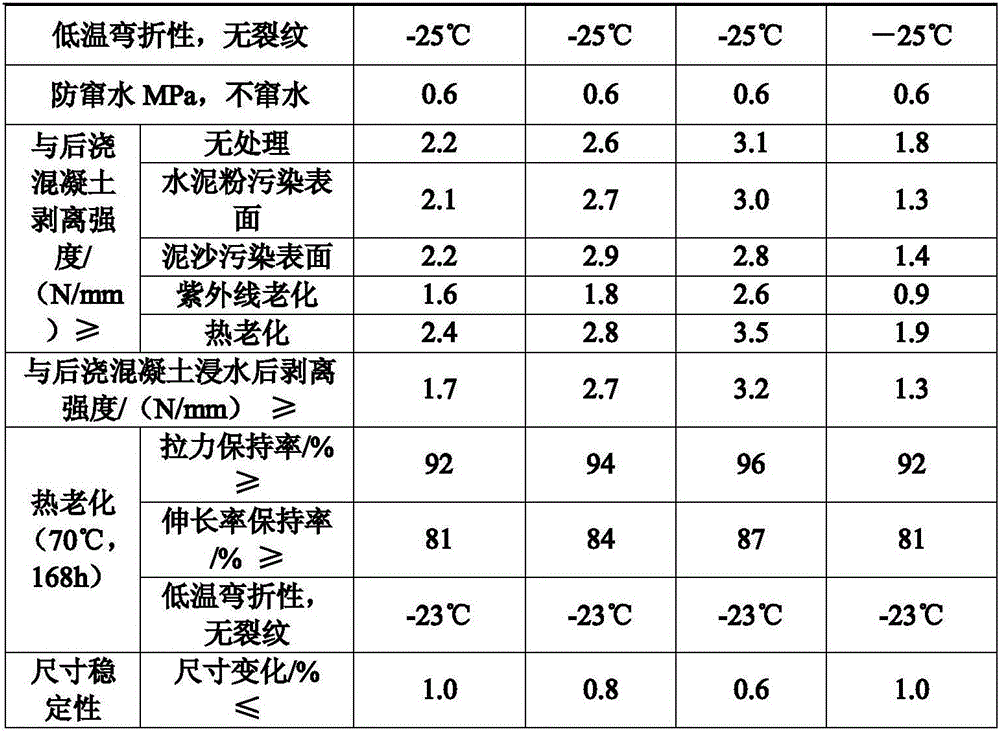

Embodiment 1

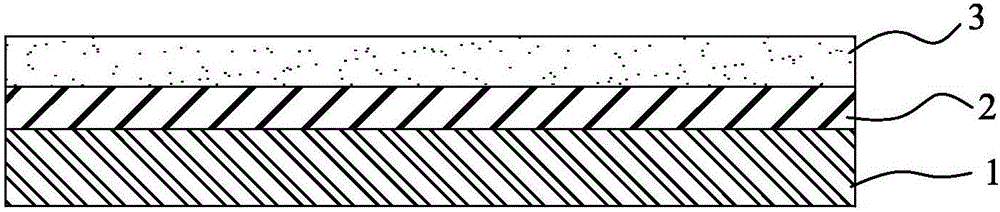

[0032] This embodiment provides a self-adhesive macromolecule pre-laid waterproof roll, such as figure 1 As shown, the waterproof membrane has a three-layer structure, including a sheet-like polymer substrate layer 1, a hot-melt pressure-sensitive adhesive layer 2 formed on the sheet-like polymer substrate layer 1, and a hot-melt pressure-sensitive adhesive layer arranged on the sheet-like polymer substrate layer. 2 on the anti-stick layer 3.

[0033] In this example, the raw materials used for the sheet polymer substrate layer 1 are high-density polyethylene pellets and low-density polyethylene pellets in a mass ratio of 1:1, which are mixed at high and low speeds and sent to the twin-screw extruder to be shaped by the die head. A waterproof sheet with a thickness of 1.0mm is made, and the temperature of each section of the twin-screw extruder is controlled, the temperature of the feeding section is at room temperature, the temperature of the compression section is 120-160°C,...

Embodiment 2

[0040] This embodiment provides a self-adhesive polymer pre-laid waterproof membrane.

[0041] The raw material used for the sheet-like polymer substrate layer 1 of the waterproof roll material in this example is a combination of high-density polyethylene and polyvinyl acetate particles in a mass ratio of 8:2.

[0042]The raw material of the hot-melt pressure-sensitive adhesive layer 2 is SIS rubber: naphthenic oil: hydrogenated petroleum resin in a mass ratio of 30:24:46, and 3‰ and 5% of the total weight of the hot-melt pressure-sensitive adhesive are added to the raw material. ‰ antioxidant bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, UV stabilizer 2-hydroxy-4-methoxybenzophenone. The thickness of the hot-melt pressure-sensitive adhesive layer 2 is 0.3mm.

[0043] The raw materials of anti-sticking mineral particles are 99.62% of special white cement, 0.3% of polycarboxylate water reducer, 0.06% of defoamer, and 0.02% of retarder. The particle size distribution is 8% ...

Embodiment 3

[0046] This embodiment provides a self-adhesive polymer pre-laid waterproof membrane.

[0047] The raw material used for the sheet-like polymer substrate layer 1 of the waterproof roll material in this example is a combination of high-density polyethylene, low-density polyethylene, and polyvinyl acetate particles in a mass ratio of 6:3:1.

[0048] The raw material of the hot-melt pressure-sensitive adhesive layer 2 is SIS rubber: polybutadiene: hydrogenated carbon nine petroleum resin in a mass ratio of 28:28:42, and 3‰ of the total weight of the hot-melt pressure-sensitive adhesive is added to the raw material , 5‰ antioxidant bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, UV stabilizer 2-hydroxy-4-methoxybenzophenone. The thickness of the hot-melt pressure-sensitive adhesive layer 2 is 0.36mm.

[0049] The raw materials of anti-sticking mineral particles are 99.62% of special white cement, 0.3% of polycarboxylate water reducer, 0.06% of defoamer, and 0.02% of retarder. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com