Wrinkling cutter and manufacturing method thereof

The invention relates to a technology for wrinkling knives and bases, which is applied in the field of new wrinkling knives and their preparation, which can solve the problems of edge cracking, increase energy consumption, shorten the life of wrinkling knives, etc., and achieve the effect of ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

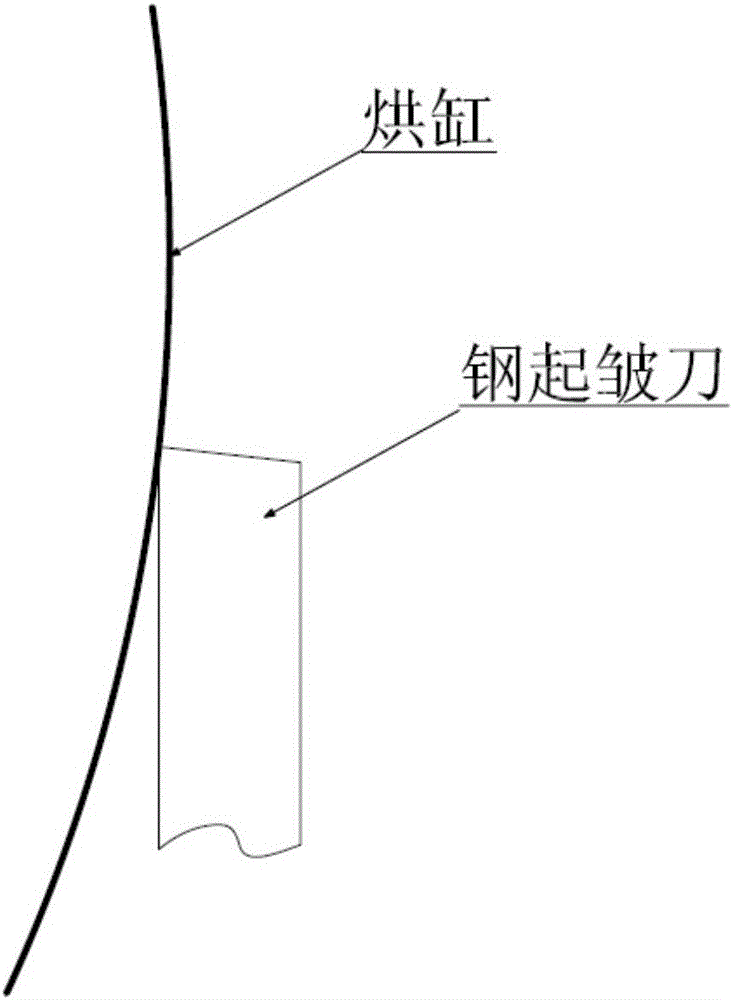

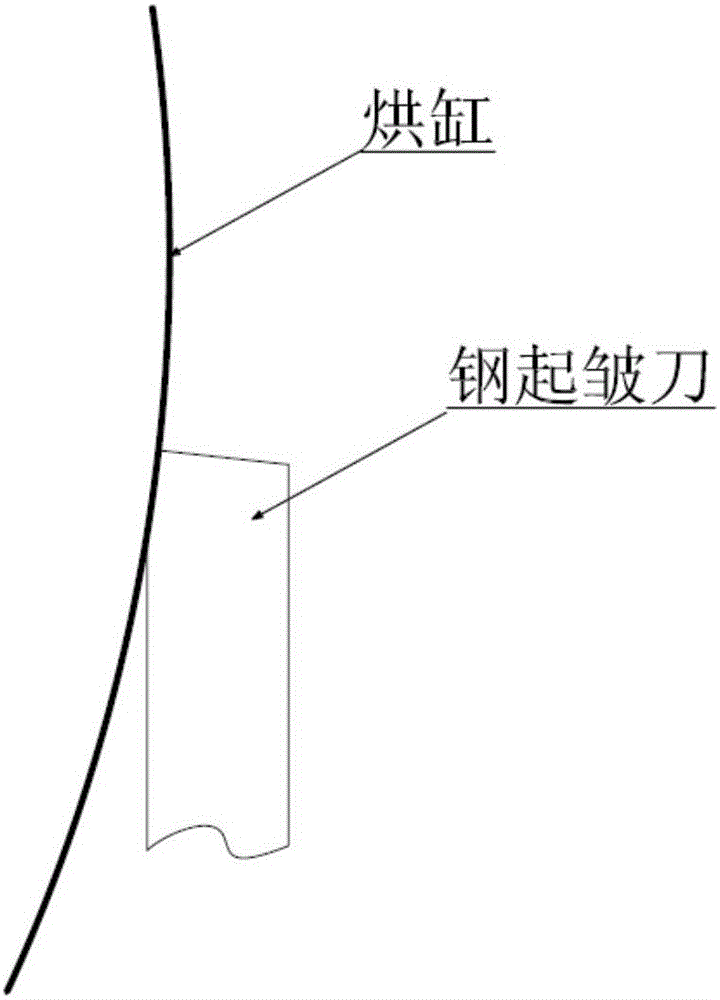

[0066] This embodiment provides a kind of wrinkling knife, its specification is 4000mm * 120mm * 1.2mm, and it is prepared through the following steps:

[0067] According to the specifications of the corrugating knife, select the steel substrate of the corresponding specification;

[0068] Pre-grind a transitional inclination angle of 5° on the surface of the base body close to the top of the drying cylinder, and the width of the pre-grinding part is 2mm;

[0069] Process the top end face of the substrate to form the structural angle of the corrugating knife, with an angle of 77°;

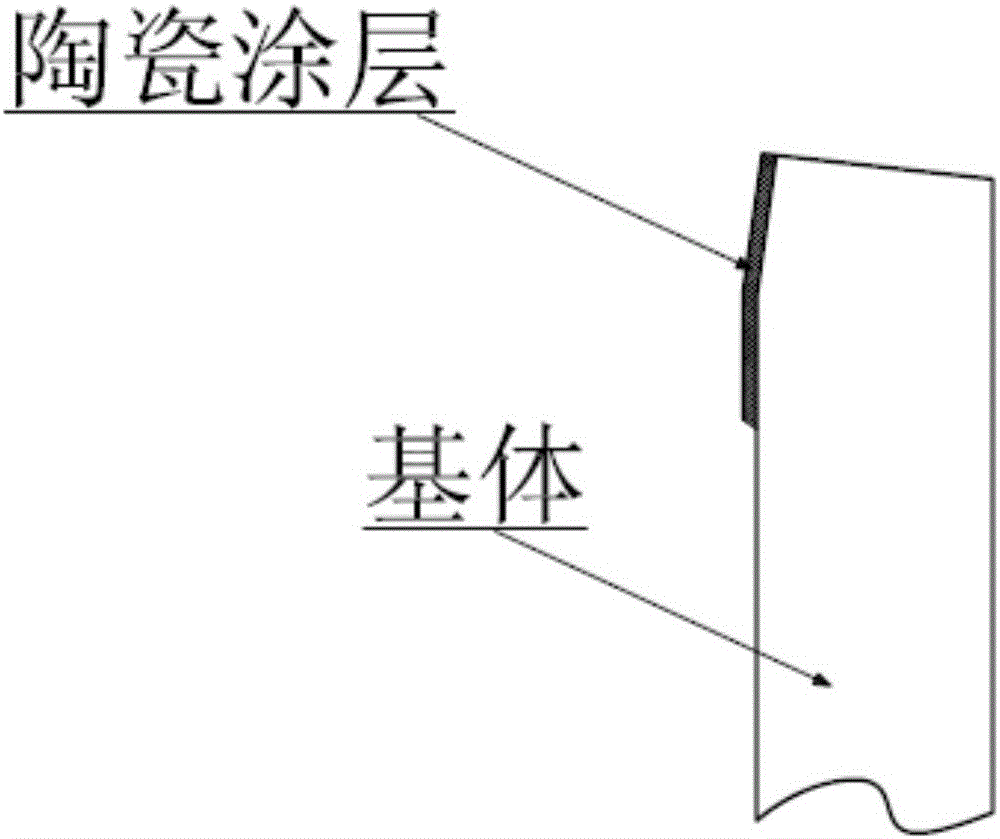

[0070] Supersonic flame spraying is used to form a coating on the top surface of the substrate and one side of the working surface. The coating material is tungsten carbon (WC) series metal powder; the coating is ground, and the thickness of the final coating is 0.08mm;

[0071] The working surface part of the substrate is processed to obtain working piles and grooves, and a corrugating knife is o...

Embodiment 2

[0098] This embodiment provides a kind of wrinkling knife, its specification is 3850mm * 120mm * 1.2mm (other dimensions are identical with embodiment 1), and it is prepared through the following steps:

[0099] According to the specifications of the corrugating knife, select the steel substrate of the corresponding specification;

[0100] Pre-grind a transitional inclination angle between 0°-15° on the surface of the base body near the top of the drying cylinder, and the width of the pre-grinding part is between 1mm-2.5mm;

[0101] Process the top end face of the substrate to form the structural angle of the corrugating knife, with an angle of 77°;

[0102] Supersonic flame spraying is used to form a coating on the top surface of the substrate and one side of the working surface. The coating material is tungsten carbon (WC) series metal powder; the coating is ground, and the thickness of the final coating is 0.08mm;

[0103] The working surface part of the substrate is proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com