A Design Method for Increased Lift Wing Tip

A design method and wingtip technology, applied in aircraft parts, ground equipment, transportation and packaging, etc., can solve the problems of increasing the complexity of the manufacturing process and increasing the weight, so as to increase the complexity of the manufacturing process, reduce the weight of the structure, increase the The effect of lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

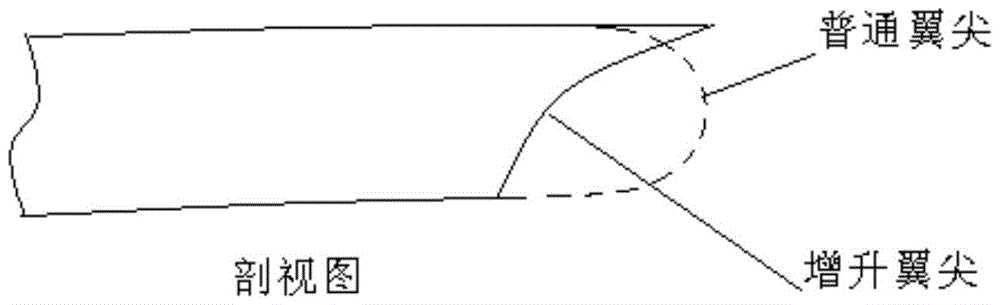

[0020] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0021] The steps of the present invention include:

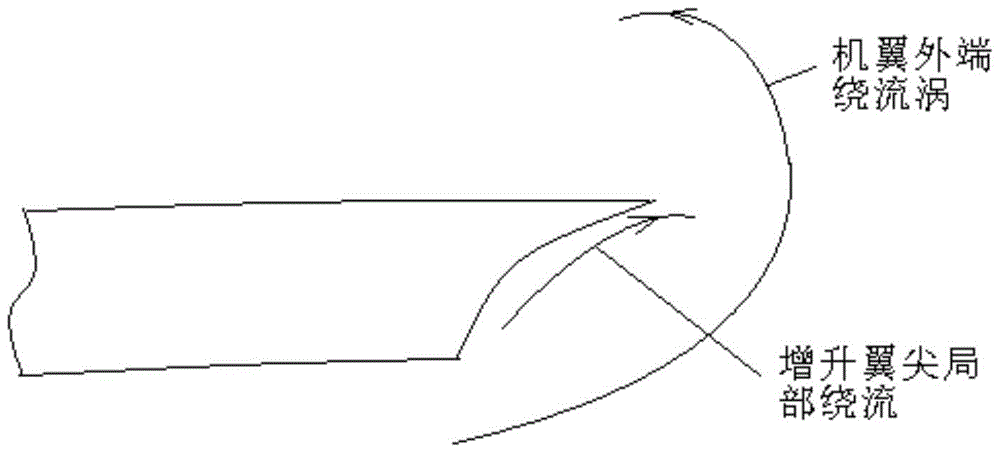

[0022] Step 1. Different from the previous design of increased wingtip, which mainly uses winglets to block the vortex flow around the wingtip, first establish a new theory that uses the reverse vortex around the wingtip to reduce the vortex flow around the wingtip. The new vorticity calculation formula is:

[0023] Γ 总 =Γ 翼尖 -Γ 增升

[0024] After the design of the special shape of the increased wing tip, the circulation of the wing tip vortex can be partially offset, thereby reducing the loss of the three-dimensional flow around the wing tip, and achieving the purpose of reducing the overall aircraft resistance and increasing the overall aircraft lift;

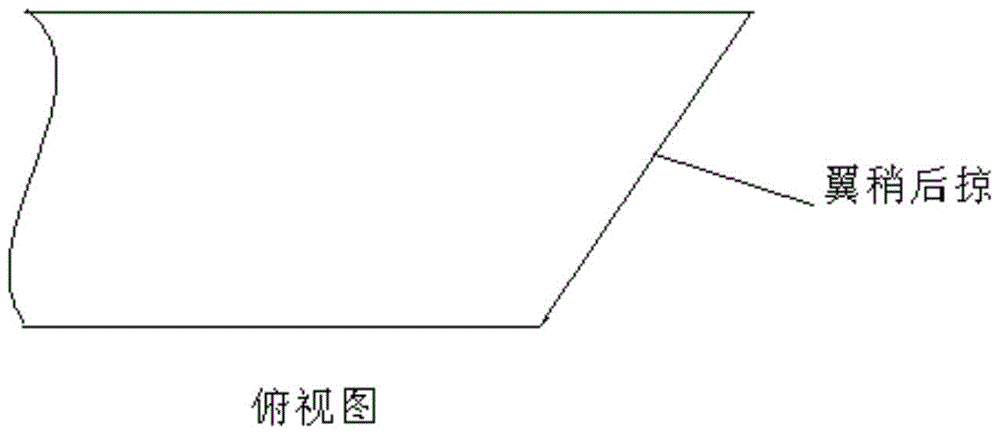

[0025] Step 2, select the appropriate wing tip average sweep angle according to the aircraft design flight M number, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com