Diamond wire ingot squarer

A diamond wire and square cutting machine technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of uncontrollable cutting size, increasing the wheelbase of cutting guide wheels, and no support at the bottom of the crystal ingot, etc., so as to avoid The effect of uncontrollable size and chipping, improvement of working environment, and avoidance of cutting size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

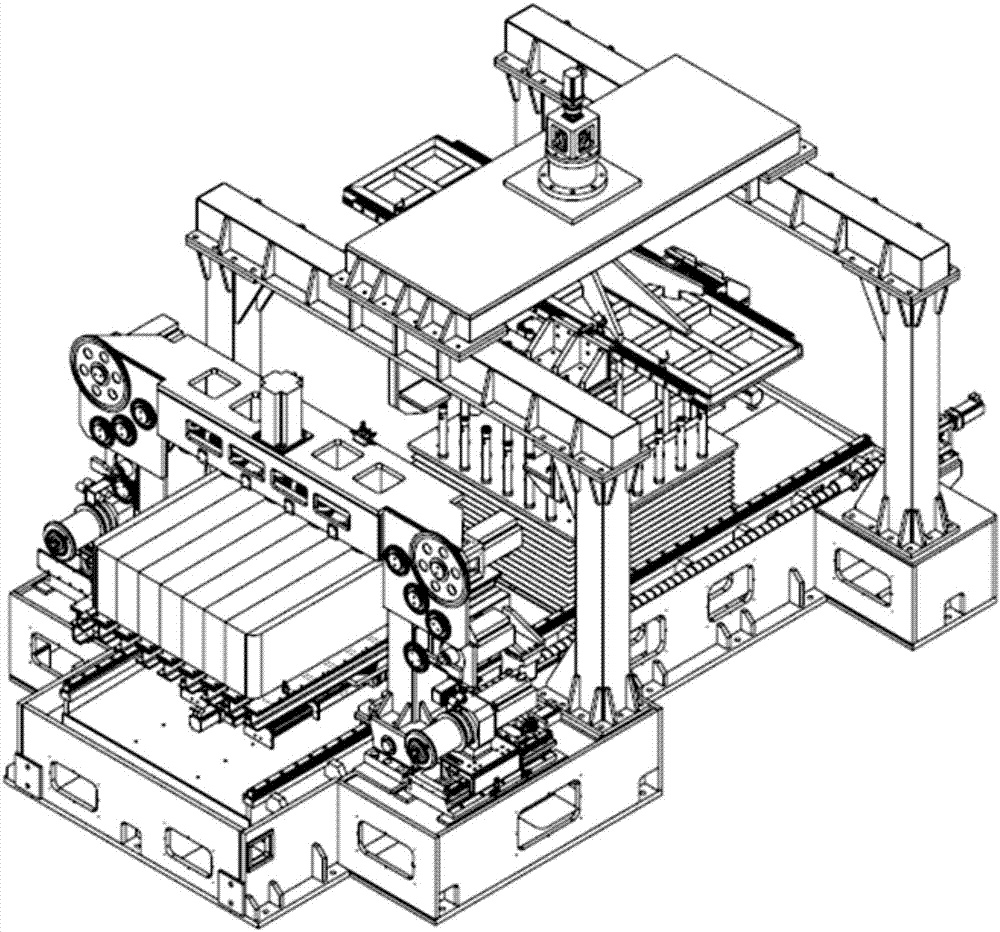

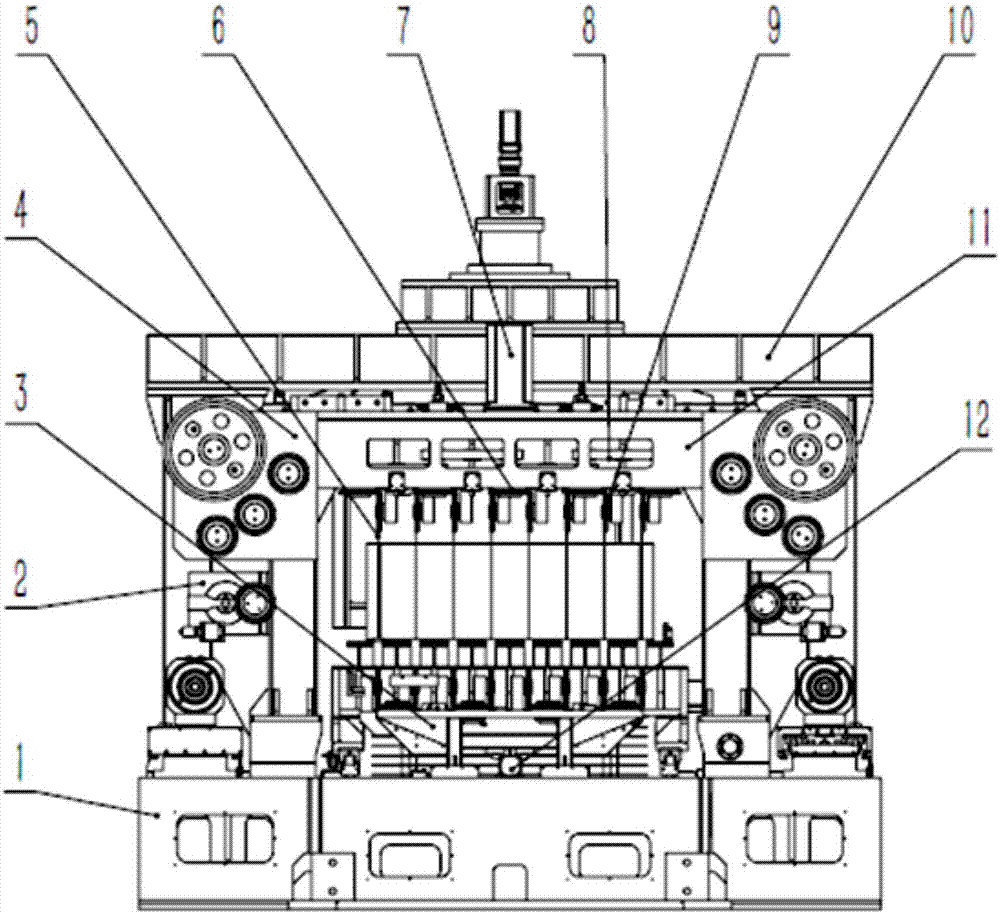

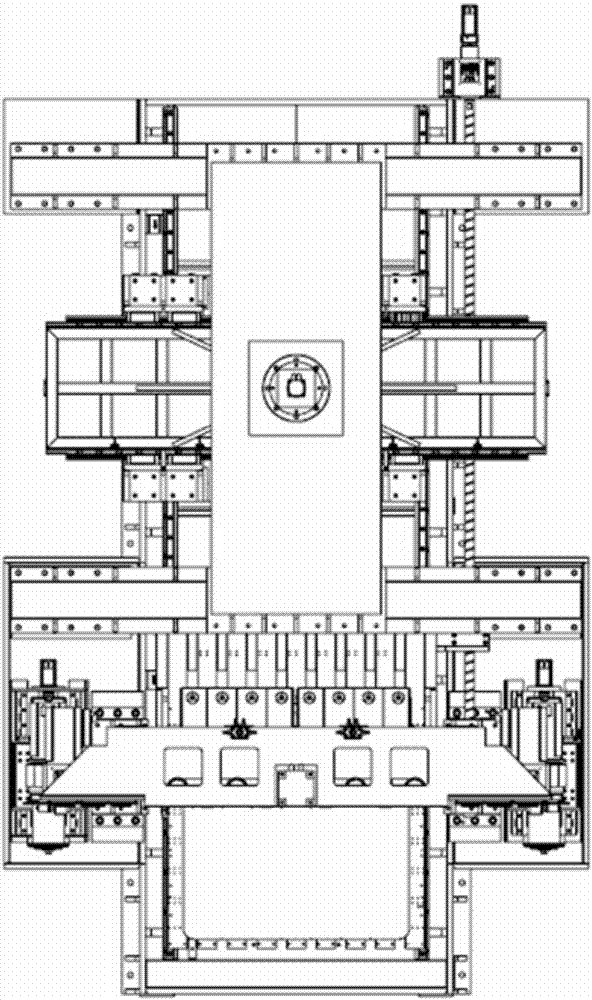

[0035] Such as Figure 1 to Figure 4 The shown diamond wire crystal ingot squarer includes a large chassis 1, a workbench 27, a workbench horizontal movement motor 13, a reducer 14, a main screw 15, a manipulator part 10, a cutting chamber part 4, a lifting mechanism 16, a retractor The wire releasing part 25 , the tension part 2 , and the bottom guide wheel part 3 can utilize the diamond wire 5 to cut the crystal ingot 26 .

[0036] Main rail 28 is housed on the described big chassis 1, and workbench 27 is housed above the main rail 28. The horizontal movement motor 13 of the workbench is installed on one side of the large chassis 1, the horizontal movement motor 13 of the workbench is connected with a speed reducer 14, and the speed reducer 14 is connected with the workbench 27 by the main screw 15, so that the workbench 27 can move along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com