Truss type oiling machine

An oiler and truss-type technology, which is applied in coatings, ceramic molding machines, and devices for coating liquid on the surface, can solve the problems of low efficiency of manual oiling, and reduce the probability of direct contact with harmful substances. Structure Sophisticated, pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

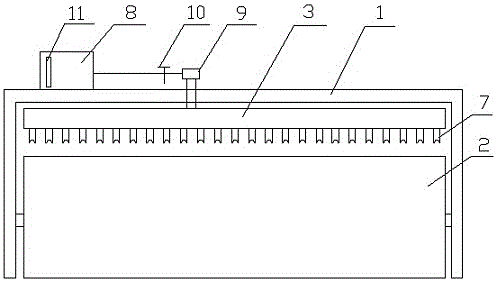

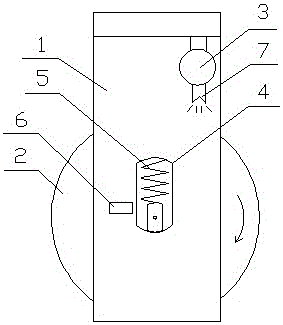

[0020] As shown in the figure, a truss-type oiler according to the present invention includes a gantry 1, a roller 2, and a fuel injection pipe 3. The roller 2 is arranged between the gantry 3, and the gantry 3 Both sides are provided with vertical waist-shaped holes 4, and springs 5 are arranged in the said waist-shaped holes 4. The lower edge of the gantry 1 is at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com