Automatic pot edge polishing device

A technology for edge grinding and cooking utensils, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc. It can solve problems such as uneven product quality, different quality of pot edges, smoothness, etc., to improve product quality, Improve efficiency and ensure personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

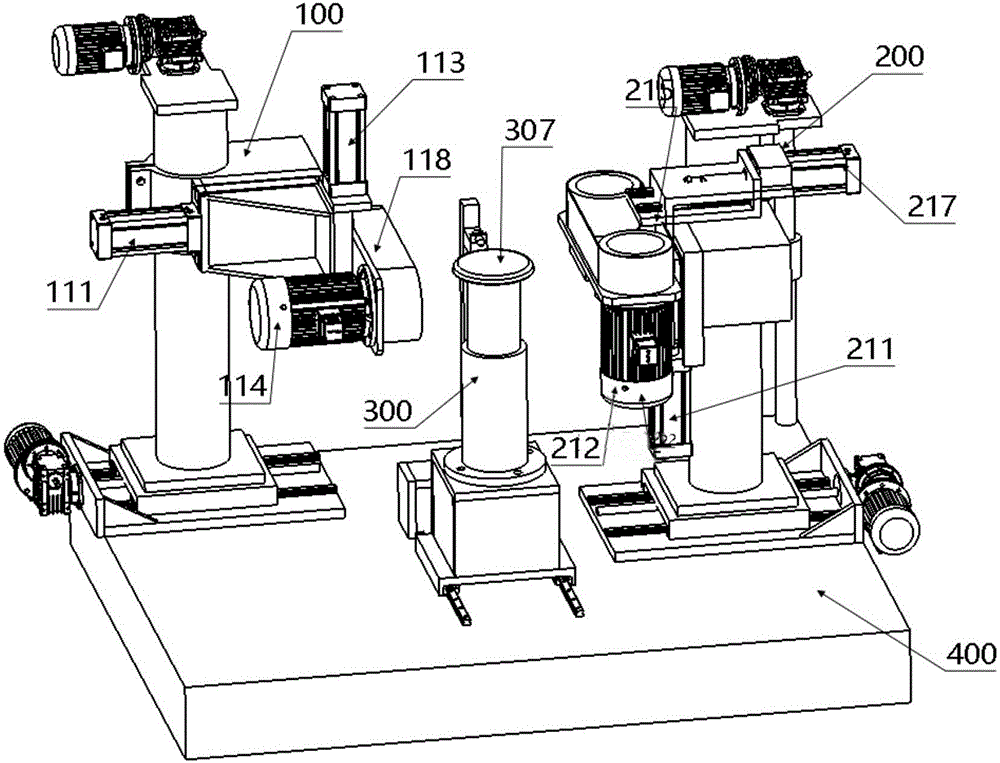

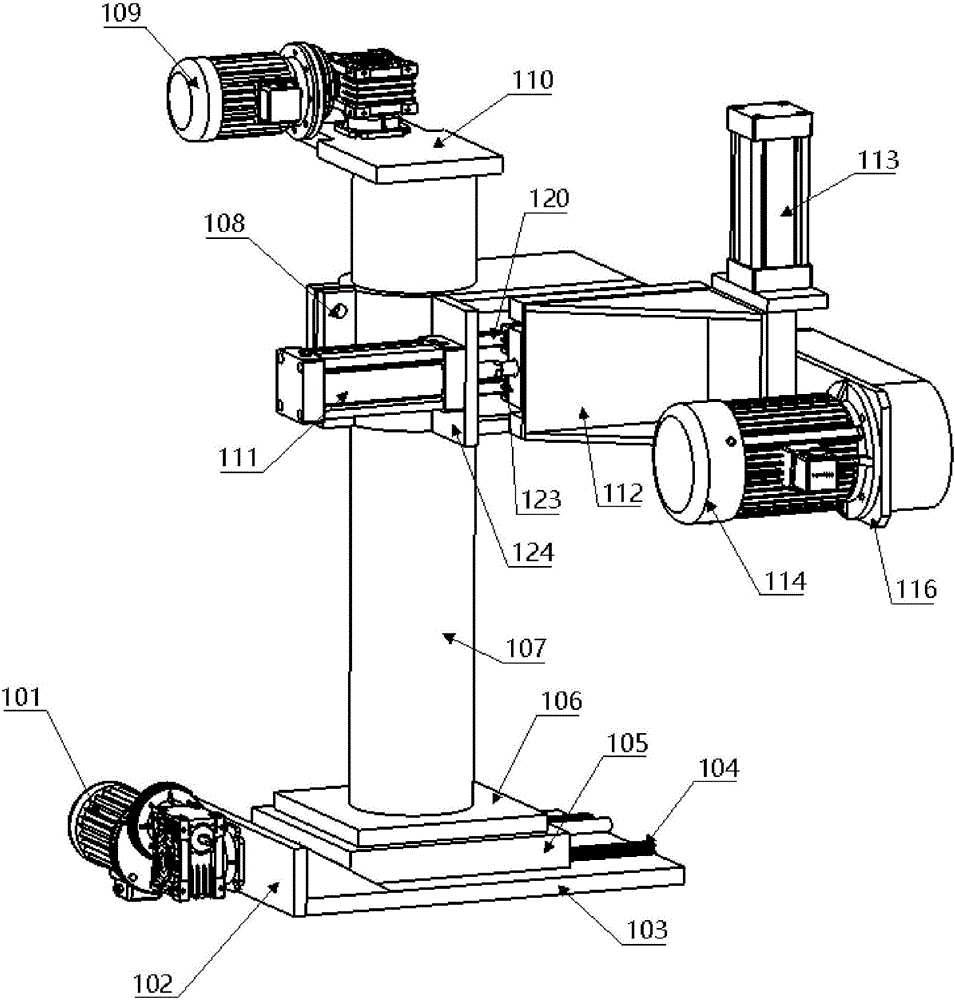

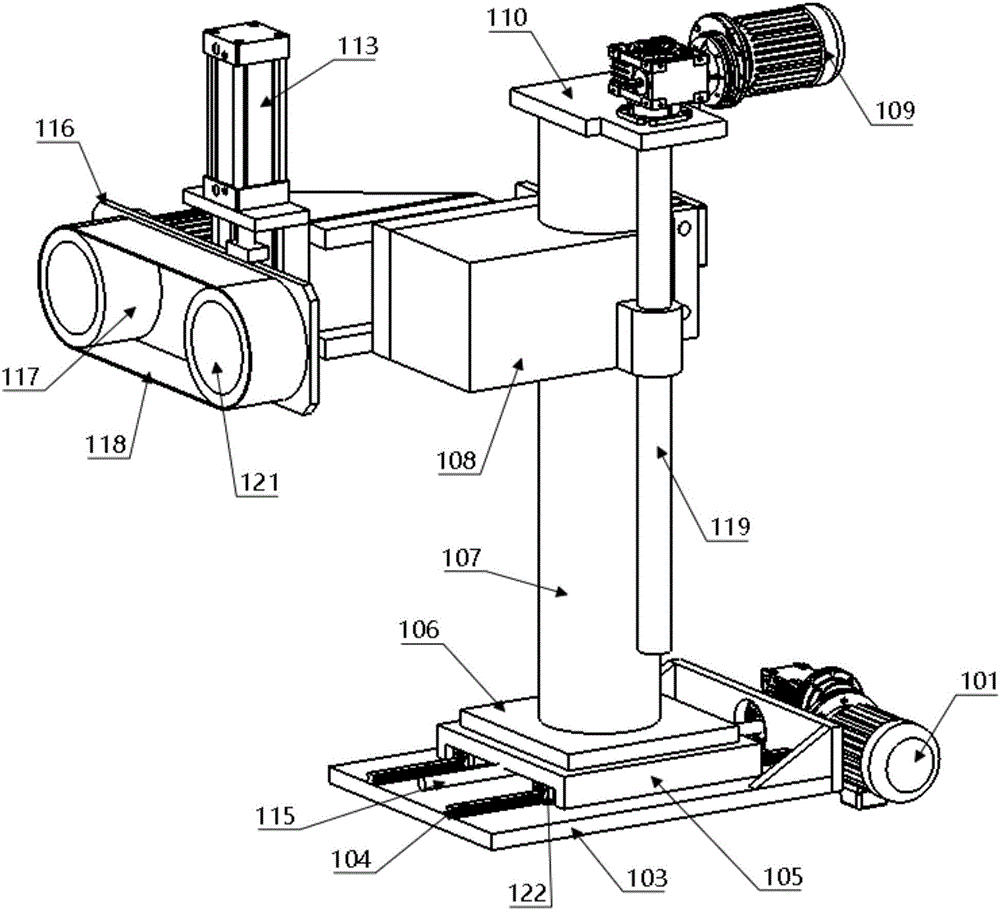

[0020] refer to Figure 1 to Figure 5 , is an automatic edging device for pots, including a device bottom plate 400, a pot rim surface edging device 100 for smoothing the pot rim surface, and a pot rim side grinder for smoothing the pot rim surface Edge device 200, is provided with die head 307 and is used for detecting whether pot is in die head 307 automatic detection pot device 300; pot edge surface edging device 100, pot edge surface edging device 100, automatic detection pot device 300 Both are arranged on the bottom plate 400 of the device.

[0021] The 100 module of the edging device for the pot edge surface can polish the surface of the pot edge smoothly, so that the surface of the pot edge feels smooth and does not hurt hands; The surface of the side of the pot feels smooth and does not hurt the hands; the automatic detection pot device 300 module is used to detect whether the pot is on the die head 307, so as to prevent the device from running dry and save energy. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com