Blade detachable steel plate drill

A detachable, steel plate drilling technology, which is used in repair drilling, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of blade tissue strength damage, hardness, strength reduction, strength damage, etc. The effect of saving processing time and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

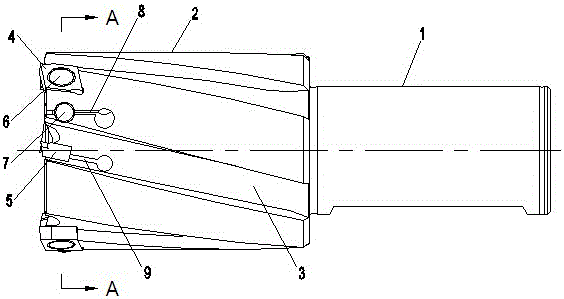

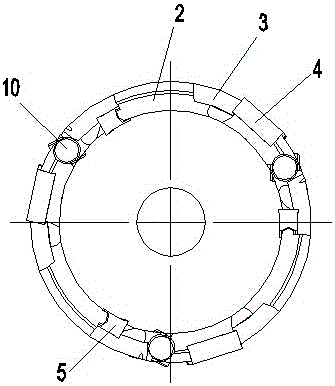

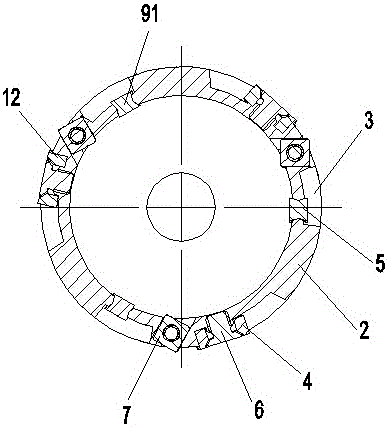

[0019] see Figure 1 to Figure 4 , The blade detachable steel plate drill in this embodiment includes a blade 4, a blade 5, a cutter body 2, a screw 6, a screw 10, and a nut 7, wherein the screw 6, the screw 10, and the nut 7 are accessories of the cutter body 2.

[0020] In this embodiment, one end of the cutter body 2 is provided with six blade positioning structures, which can respectively install three blades 4 and three blades 5, and each blade communicates with (corresponds to) a chip removal groove 3 .

[0021] In this embodiment, the cuboid positioning groove 12 (a positioning structure) of the blade 4 processed on the cutter body 2 is closely attached to the mounting part (four angled surfaces) of the blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com