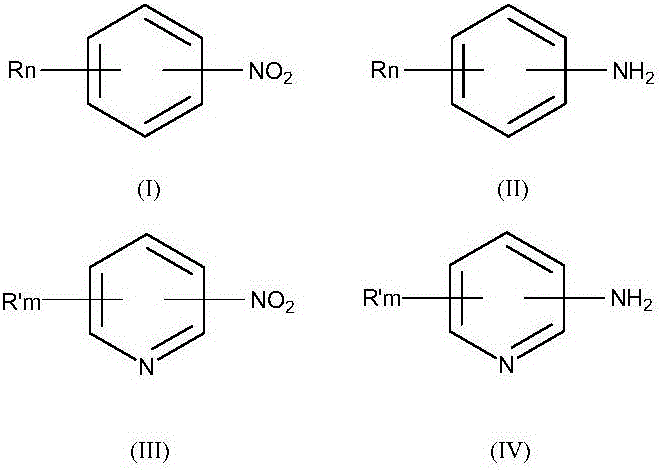

Activated carbon loaded compound metal catalyst, preparation method and application thereof.

A composite metal and catalyst technology, which is applied in the field of activated carbon-supported composite metal catalyst and its preparation, can solve problems in the field of catalytic hydrogenation, and achieve the effects of many application times, shortened reaction time, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

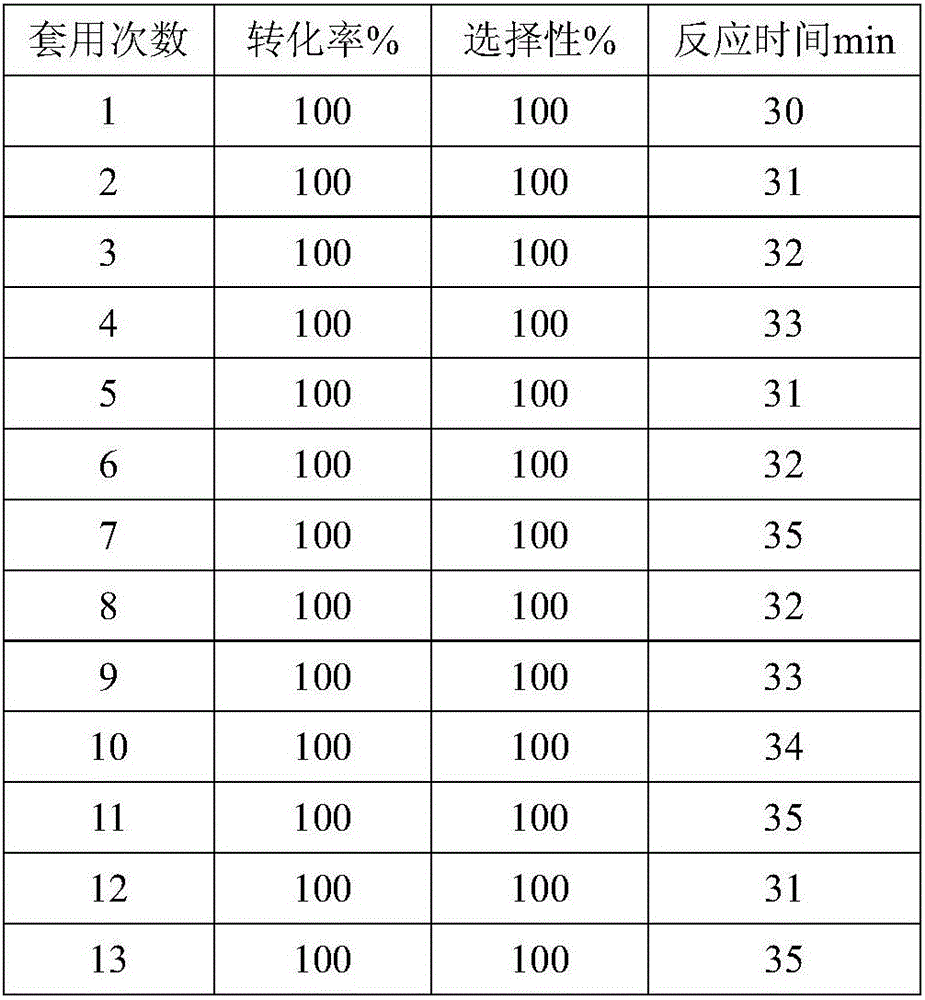

Embodiment 1

[0048] The physical parameters of the carrier activated carbon: the ash content is 3.0wt%, and the specific surface area is 1500m 2 / g, the proportion of micropore specific surface area is not less than 75%, and the particle size of activated carbon is D 10 :2.5μm, D 50 : 12 μm, D 90 : 30 μm; the material of the activated carbon is coconut shell.

[0049] Weigh the palladium chloride corresponding to 0.5g palladium, the platinum dichloride corresponding to 0.3g platinum and 2.5g sodium citrate, add ethylene glycol and stir until completely dissolved; mix 10g gac with 50ml ethylene glycol to prepare Make a slurry, heat up to 50°C and stir for 2 hours, then drop into the ethylene glycol solution of the active component, and stir at a constant temperature for 5 hours; add ferric chloride corresponding to 0.1g of iron and chloride corresponding to 0.2g of zinc For zinc, continue to stir at constant temperature for 5 hours; add dropwise an ethylene glycol solution of sodium hydr...

Embodiment 2

[0051] The physical parameters of the carrier activated carbon: the ash content is 4.0wt%, and the specific surface area is 1200m 2 / g, the proportion of micropore specific surface area is not less than 70%, and the particle size of activated carbon is D 10 : 4.5 μm, D 50 : 15μm, D 90 : 32 μm; the material of the activated carbon is coconut shell.

[0052] Weigh the palladium chloride corresponding to 0.5g palladium, the platinum dichloride corresponding to 0.3g platinum and 3.5g sodium citrate, add ethylene glycol and stir until completely dissolved; mix 10g gac with 40ml ethylene glycol to prepare Form a slurry, heat up to 80°C and stir for 2 hours, then drop into the ethylene glycol solution of the active component, and stir at a constant temperature for 3 hours; add ferric chloride corresponding to 0.1g of iron and chloride corresponding to 0.2g of zinc For zinc, continue to stir at constant temperature for 5 hours; add dropwise an ethylene glycol solution of sodium hyd...

Embodiment 3

[0054] The physical parameters of the carrier activated carbon: the ash content is 3.0wt%, and the specific surface area is 1500m 2 / g, the proportion of micropore specific surface area is not less than 75%, and the particle size of activated carbon is D 10 :2.5μm, D 50 : 12 μm, D 90 : 30 μm; the material of the activated carbon is coconut shell.

[0055] Weigh the palladium chloride corresponding to 0.6g palladium, the platinum dichloride corresponding to 0.2g platinum and 2.5g sodium citrate, add ethylene glycol and stir until completely dissolved; mix 10g gac with 50ml ethylene glycol to prepare Make a slurry, heat up to 50°C and stir for 2 hours, then drop into the ethylene glycol solution of the active component, and stir at a constant temperature for 5 hours; add ferric chloride corresponding to 0.2g of iron and chloride corresponding to 0.3g of zinc Zinc, continue stirring at constant temperature for 5 hours; add dropwise an ethylene glycol solution of sodium hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com