Bacillus amyloliquefaciens and method for preparing succinyl ononin in nonaqueous phase

A technology of amylolytic spores and succinyl formonone, which is applied in the field of biocatalysis, can solve the problems of high cost and cumbersome steps, and achieve the effects of low cost, simple separation and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

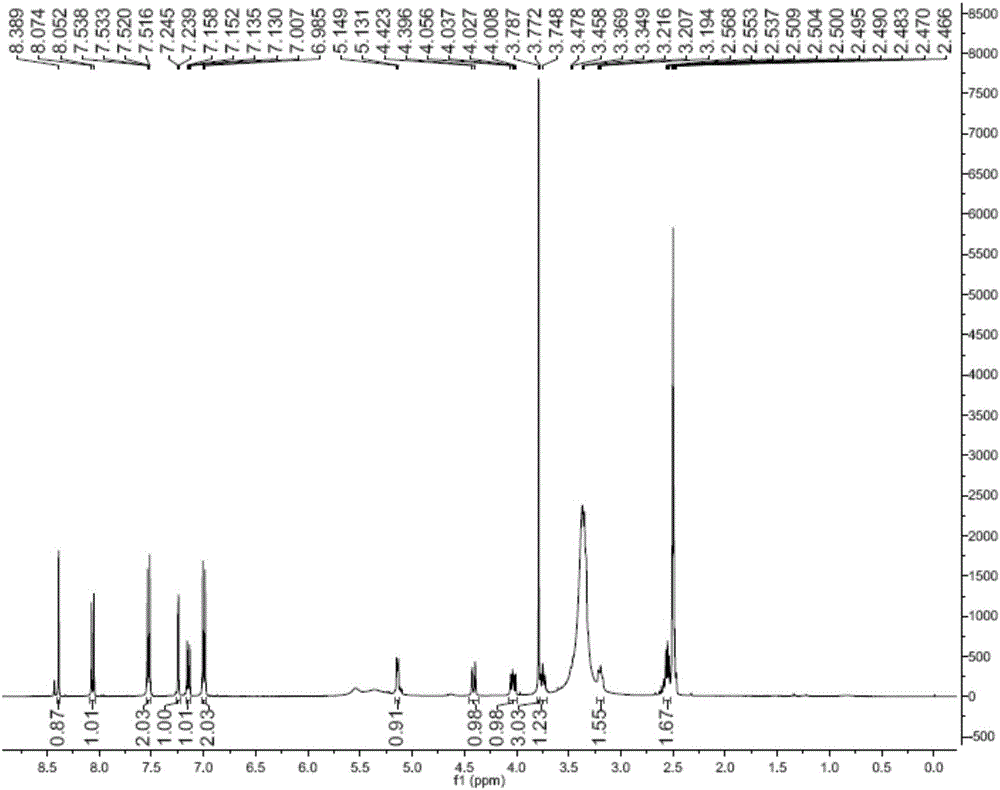

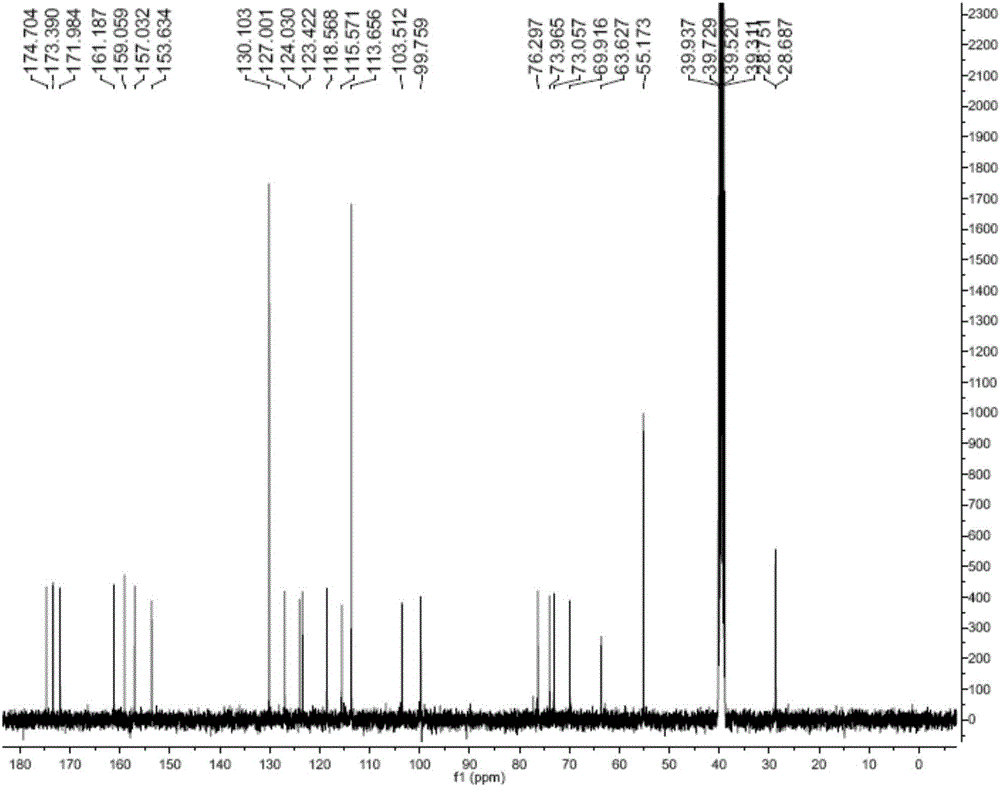

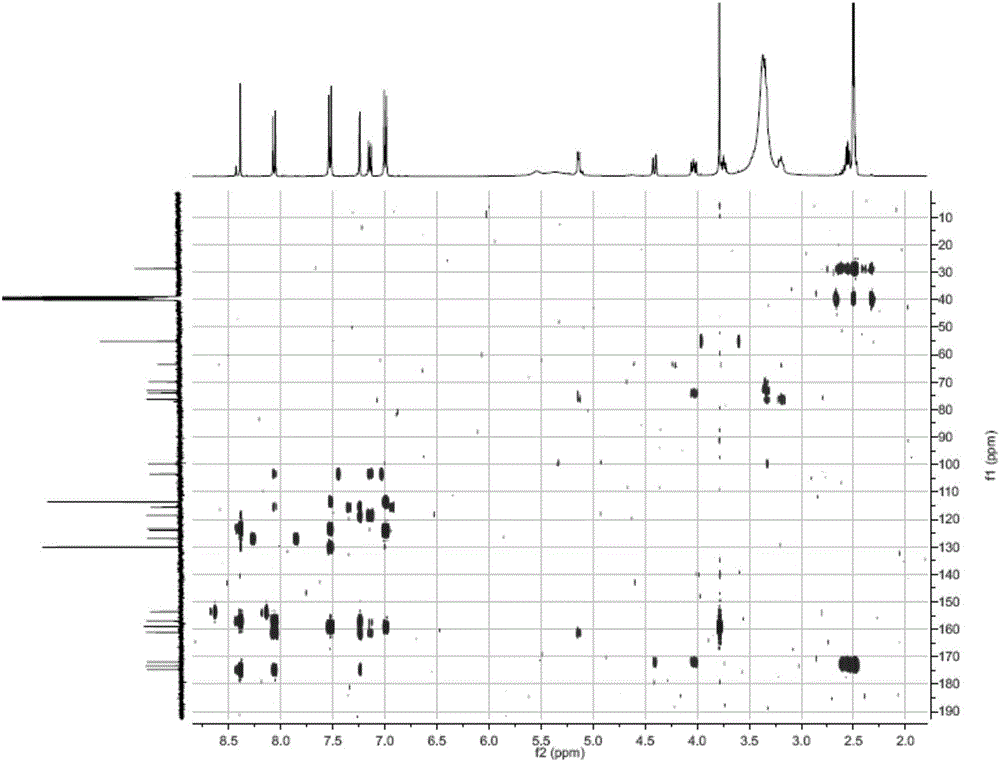

Image

Examples

Embodiment 1

[0029] Screening and identification of strains for producing succinylated formononetin in non-aqueous phase

[0030] The soil samples for strain isolation were from the soils with severe chemical pollution and the soil of medicinal botanical gardens in various regions of Jiangsu Province. Extremophiles resistant to organic solvents were screened and isolated from the soil samples. Take about 1g of soil sample, put it into a conical flask filled with 20mL screening medium, 30°C, 180r min -1 Shake culture in a water bath for 24 hours, and transfer 3 times with 5% inoculum. After appropriate dilution of the culture solution, spread it with LB plate medium, incubate at 30°C for 24 hours, observe the colony shape, and then pick a single colony on the LB plate medium for streak isolation to obtain a single clone. numbered and stored in cryopreservation.

[0031] Using sucrose as the carbon source for the growth of organic solvent-resistant bacteria, adding 20% (v / v) dimethylform...

Embodiment 2

[0037] Fermentation of Bacillus amyloliquefaciens FJ18 and preparation of resting cells

[0038] Fermentation of Bacillus amyloliquefaciens FJ18 was inoculated into the seed medium: yeast extract 5.0g / L, peptone 10.0g / L, NaCl 10.0g / L, pH7.0, cultured at 30°C, 200rpm for 12 hours. Expansion medium, fermentation medium, its components and contents are: sucrose 20g / L, yeast powder 15g / L.KH 2 PO 4 1.0g / L, CaCl 2 0.8g / L. The pH was adjusted to 8.0 with NaOH. The seed solution was inoculated into the expansion medium and the fermentation medium at 0.5% (v / v), and cultivated at 30° C. and 200 rpm for 12 hours. After centrifuging at 10000rpm for 15 minutes, the bacterial cells were collected, washed 1-2 times with physiological saline, and the resting cells of Bacillus amyloliquefaciens FJ18 were obtained.

Embodiment 3

[0040] The thalline cell fermentation broth in Example 2 was filtered to obtain wet thalline. The raw material solution, ie the reaction solution, is prepared with dimethyl sulfoxide, formononetin, sucrose and phosphate buffer. The ratio of organic solvent dimethyl sulfoxide in the reaction solution is 20% (v / v), formononetin 0.5g / L, the molar concentration of phosphate buffer is 150mmol / L, the pH of phosphate buffer is 8.0, and the sucrose concentration is 50g / L. Disperse the wet bacteria obtained above in the reaction solution, add it to the reactor, cultivate it at 30°C and 200 rpm for 24 hours, centrifuge at 10,000 rpm for 10 minutes to obtain the supernatant of the reaction solution, and detect and analyze the formononetin conversion by HPLC The rate is 97.2%.

[0041] The product is separated with a macroporous resin, and an appropriate amount of resin is taken, soaked in ethanol for 24 hours, and then resin fragments and sundries are removed. Wet Packing Rinse wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com