Tea bran soap and preparation method thereof

A technology for dry tea and dry soap, applied in the field of washing, can solve the problems of inability to achieve good efficacy, inconspicuous efficacy, short duration of efficacy, etc., and achieve the effects of good market prospects, improved ductility, and prolonged efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

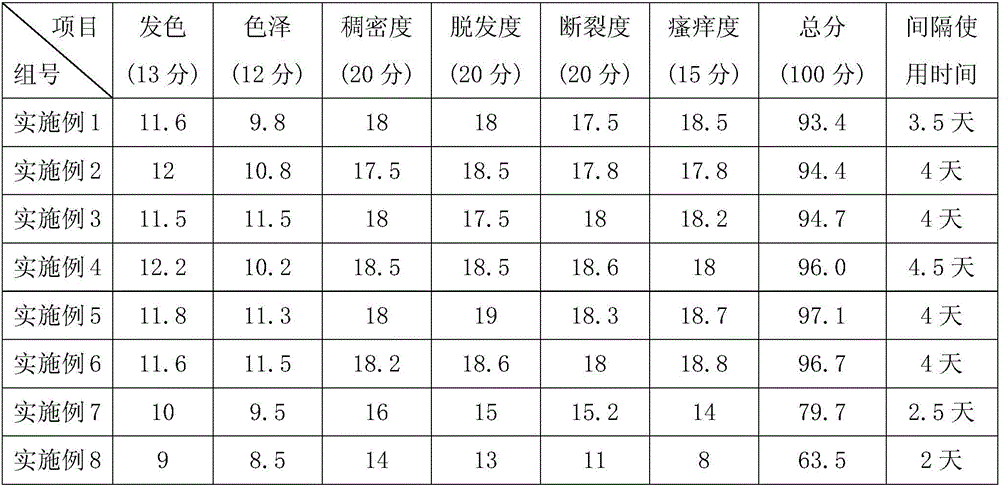

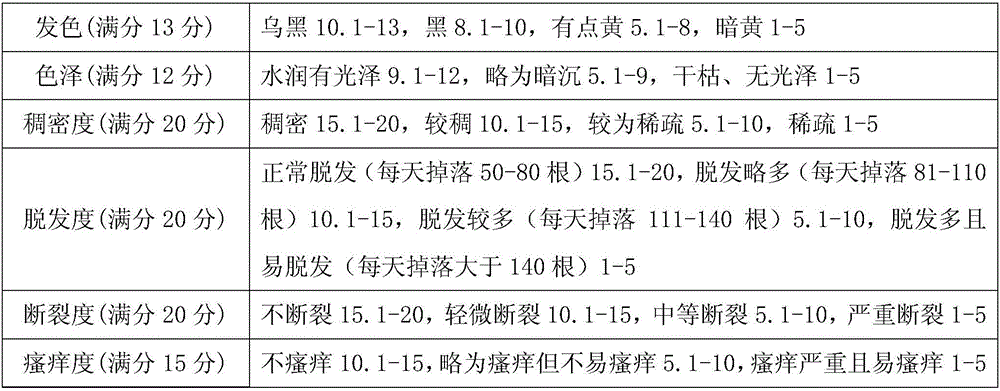

Examples

Embodiment 1

[0027] A tea tree soap, mainly made of the following raw materials in parts by weight: 25g of tea tree, 35g of vegetable oil, 5g of sodium hydroxide, 15g of rice extract, 10g of glycerin, 4g of extract of mugwort leaves, 5g of horsetail ointment, 5g of rose branch and white Perilla oil 3g; Wherein, the vegetable oil is olive oil, the rice extract is the slurry obtained by adding 8 times the weight of water to the rice and grinding and filtering, and the Artemisia argyi extract is obtained by directly squeezing the juice from fresh Artemisia argyi.

[0028] The preparation method of described tea dead soap comprises the following steps:

[0029] 1) Preparation of materials: Weighing the raw materials according to the above parts by weight; then, crushing and grinding the tea leaves and rose branches into fine powders respectively, and passing the obtained fine powders through a 150-mesh sieve for later use;

[0030] 2) Soap solution pretreatment: first, cool the rice extract to...

Embodiment 2

[0034] A kind of tea dead soap, mainly made of the following raw materials in parts by weight: 30g of tea dead, 40g of vegetable oil, 5.5g of sodium hydroxide, 17g of rice extract, 11g of glycerin, 5g of extract of mugwort leaf, 6g of horsetail paste, 6g of rose branch and Perilla seed oil 3.5g; Wherein, the vegetable oil is olive oil, the rice extract is the slurry obtained after rice is ground with 9 times the weight of water and filtered, and the Artemisia argyi extract is obtained by directly squeezing the juice from fresh Artemisia argyi .

[0035] The preparation method of described tea dead soap comprises the following steps:

[0036] 1) Preparation of materials: weighing the raw materials according to the above parts by weight; then, crushing and grinding the tea leaves and rose branches into fine powders respectively, and passing the obtained fine powders through a 160-mesh sieve for later use;

[0037] 2) Soap solution pretreatment: first, cool the rice extract to 1...

Embodiment 3

[0041] A kind of tea dead soap, which is mainly made of the following raw materials in parts by weight: 32g of tea dead, 42g of vegetable oil, 5.9g of sodium hydroxide, 18.5g of rice extract, 12g of glycerin, 6g of extract of mugwort leaves, 7g of horsetail paste, and 7g of rose branches and white perilla oil 4g; wherein, the vegetable oil is olive oil, the rice extract is the slurry obtained by adding 10 times the weight of water to the rice after grinding and filtering, and the Artemisia argyi extract is obtained by directly squeezing the juice from fresh Artemisia argyi .

[0042] The preparation method of described tea dead soap comprises the following steps:

[0043] 1) Preparation of materials: weighing the raw materials according to the above parts by weight; then, crushing and grinding the tea leaves and rose branches into fine powders respectively, and passing the obtained fine powders through a 170-mesh sieve for later use;

[0044] 2) Soap solution pretreatment: fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com