Automatic cage rewinder

A fully automatic netting and rewinding machine technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of low work efficiency, uneven cutting edges, manual cutting of base paper, etc., and achieve labor saving , neat cutting edge, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

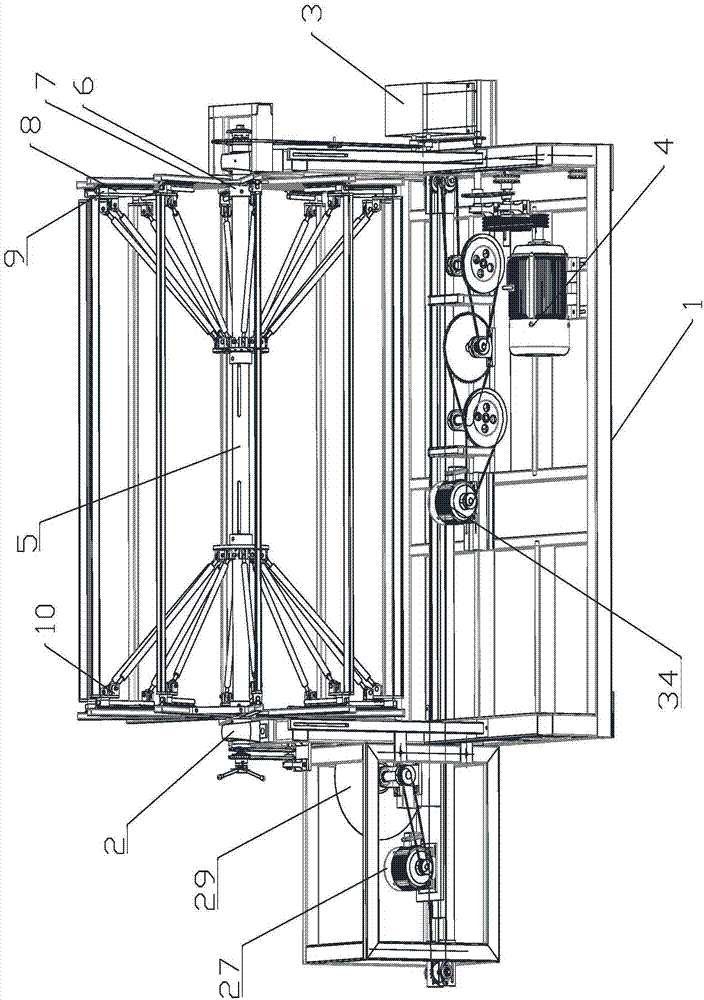

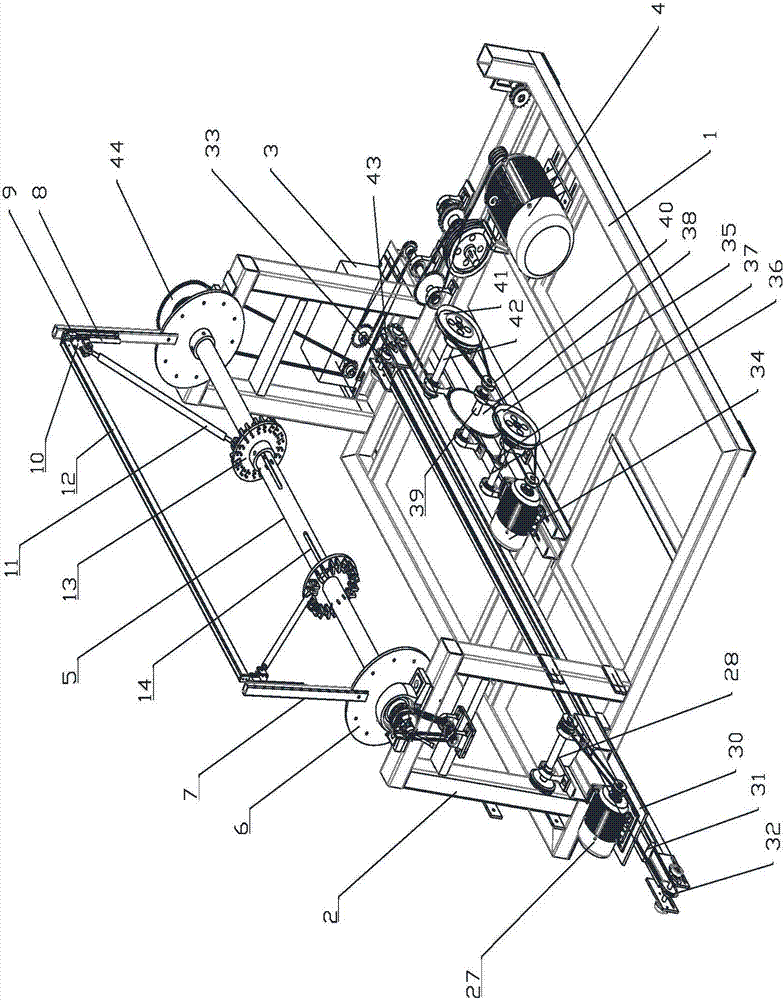

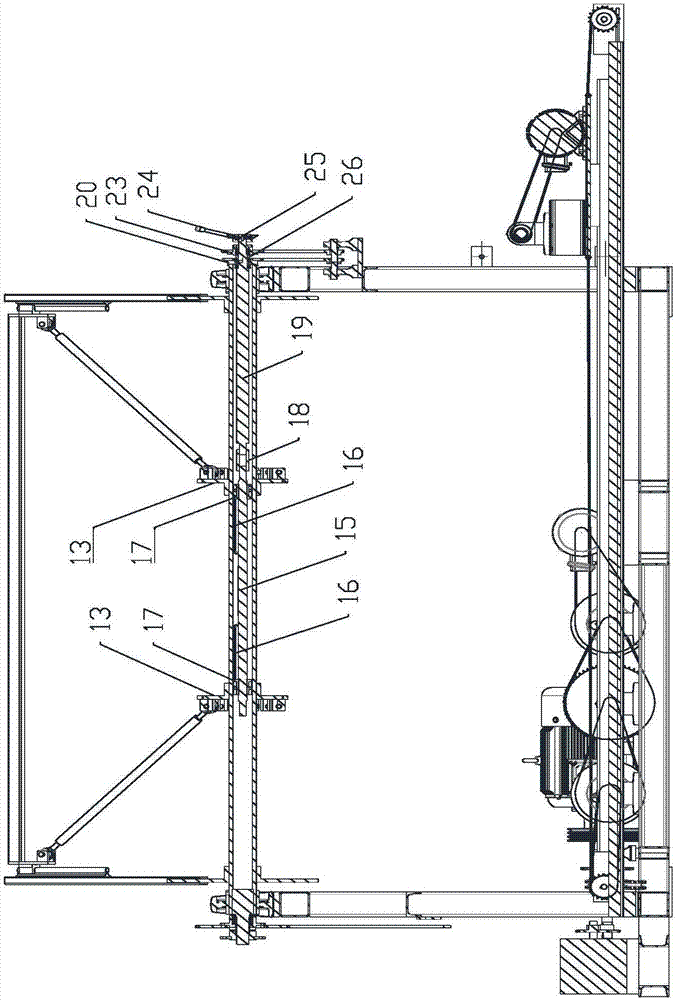

[0017] Such as figure 1 , figure 2 As shown, the fully automatic cage rewinding machine includes a frame 1, a paper cutting device is provided on the frame 1, and a stand 2 is arranged symmetrically on both sides of the frame 1, and a cage is arranged on the stand 2 As for the paper winding device, the cage winding device is chain-driven with a gearbox 3, and the gearbox 3 is connected with a third motor 4 for transmission.

[0018] The cage winding device includes a cage main shaft 5, and the two ends of the cage main shaft 5 are provided with a cage disc 6, and two umbrella column discs 13 are sleeved on the cage main shaft 5, so that Described two umbrella column discs 13 are arranged symmetrically about cage main shaft 5, and described two umbrella column discs 13 are arranged between two cage discs 6, and described each cage disc 6 is provided with two Root net cage side column 7, described net cage side column 7 is provided with line rail 8 near the side of umbrella c...

Embodiment 2

[0029] Such as figure 1 , figure 2 As shown, the automatic cage rewinding machine includes a frame 1, a paper cutting device is provided on the frame (1), and a stand 2 is arranged symmetrically on both sides of the frame 1, and a stand 2 is arranged on the stand 2 A cage winding device, the cage winding device is chain-driven with a gearbox 3, and the gearbox 3 is connected with a third motor 4 through transmission.

[0030] The cage winding device includes a cage main shaft 5, and the two ends of the cage main shaft 5 are provided with a cage disc 6, and two umbrella column discs 13 are sleeved on the cage main shaft 5, so that Describe two umbrella column discs (13) to be arranged symmetrically about cage main shaft 5, described two umbrella column discs 13 are located between two cage discs 6, set on each cage disc 6 There are six net cage side columns 7, and the side column 7 of the net cage is provided with a line track 8 near the umbrella column disc 13, and the line...

Embodiment 3

[0041] Such as figure 1 , figure 2 As shown, the automatic cage rewinding machine includes a frame 1, a paper cutting device is provided on the frame (1), and a stand 2 is arranged symmetrically on both sides of the frame 1, and a stand 2 is arranged on the stand 2 A cage winding device, the cage winding device is chain-driven with a gearbox 3, and the gearbox 3 is connected with a third motor 4 through transmission.

[0042] The cage winding device includes a cage main shaft 5, and the two ends of the cage main shaft 5 are provided with a cage disc 6, and two umbrella column discs 13 are sleeved on the cage main shaft 5, so that Describe two umbrella column discs (13) to be arranged symmetrically about cage main shaft 5, described two umbrella column discs 13 are located between two cage discs 6, set on each cage disc 6 There are ten net cage side columns 7, and the side column 7 of the net cage is provided with a line track 8 near the side of the umbrella column disc 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com